Cleaning and Disposal

• All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the

duration of the sanding project. Vacuum filter bags should be changed frequently.

• Plastic drop cloths should be gathered up and disposed of along with any dust chips or

other removal debris. They should be placed in sealed refuse receptacles and disposed of

through regular trash pick-up procedures. During clean up, children and pregnant women

should be kept away from the immediate work area.

• All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

Operating Instructions

WARNING: To reduce the risk of serious personal injury, read and follow all important

safety warnings and instructions prior to using this tool.

Switch

To turn the tool ON, hold it as shown in Figure 1 and push the portion of the switch marked

"I". To turn the tool OFF, push the portion of the switch marked "O".

Operation (Figure 1)

Grasp product as shown in figure 1 and turn it on. NOTE: Do not rest fingers on platen

during use. Move it in long sweeping strokes across the surface, letting it do the work. Light

pressure is all that is required for sanding, polishing or scrubbing. Excessive pressure will

slow the tool and produce inferior results. Check your work often, product is capable of

removing material rapidly.

WARNING: Shock hazard. Under no circumstances should this product be used near water.

CAUTION: To reduce the risk of injury, turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories.

Detail Sanding

Your tool is equipped with a teardrop base which allows you to use it on large flat surfaces

and tight spots or corners.

The pad tips may wear unevenly, depending on use. The pads are designed to allow you to

interchange and /or rotate the diamond tip.

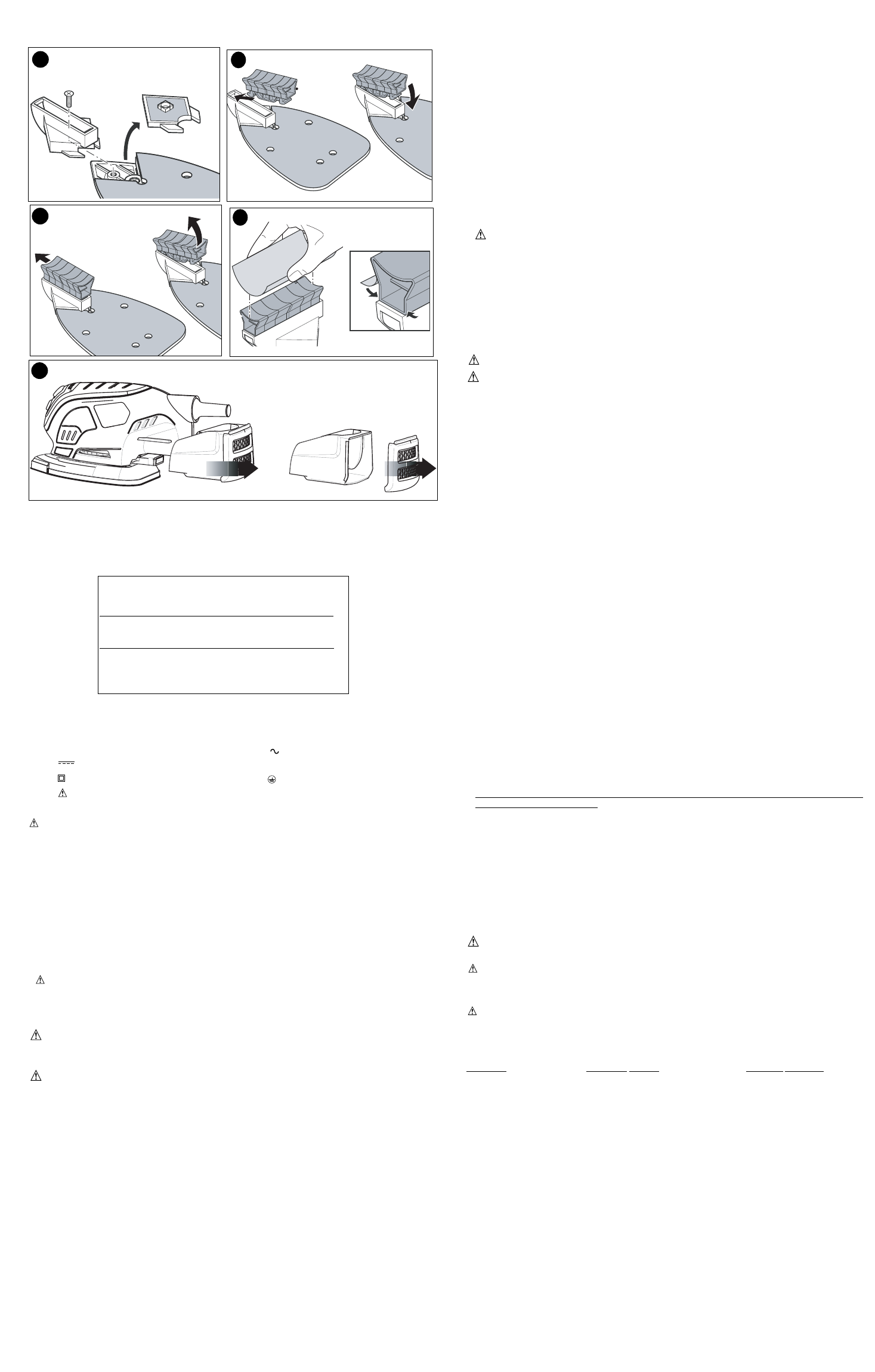

Fitting sanding sheets (Fig. 2)

• Detach the two diamond-shaped tips from the sanding sheet.

• Hold the tool with the sanding base facing upwards.

• Place the sanding sheet onto the sanding base.

The diamond-shaped tip can be reversed and replaced when worn.

• When the front part of the tip is worn, detach it from the sheet, reverse it and press it onto

the sanding base again.

• When the whole tip is worn, remove it from the sanding base and fit a new tip.

Tip of the Sanding Base (Fig. 3)

When the sanding base tip is worn, it can be reversed or replaced.

• Reverse or replace the worn part.

Finger Attachment (Fig. 4)

The finger attachment is used for fine detail sanding.

• Remove the screw.

• Remove the diamond-shaped tip holder from the sanding base.

• Fit the finger attachment onto the sanding base.

• Fit and tighten the screw.

• Align the sanding sheet with the finger attachment.

Contour Holder Attachment (Fig. 5)

• The contour sanding pieces are for sanding curved surfaces and grooves.

• Remove the screw.

• Remove the diamond-shaped tip holder from the sanding base.

• Fit the contour holder onto the sanding base.

• Fit and tighten the screw.

Fitting and Removing a Contour Piece (Fig. 6 & 7)

• Choose the contour sanding piece profile most suitable for your application.

• Place one end of the contour sanding piece into the recess at the front end of the contour

holder.

• Push the other end of the contour sanding piece until it clicks into place.

• T

o remove the contour sanding piece, push it forward then pull the rear end out of

the contour holder (fig. 7).

Fitting a Sanding Sheet Onto a Contour Sanding Piece (Fig. 8)

• Align the sanding sheet with the contour sanding piece.

• Press the sanding sheet onto the contour sanding piece, making

sure that the sanding sheet follows the shape of the profile.

Dust Extraction (Fig. 9)

To Empty Dust Canister:

• The dust canister should be emptied after every 10 minutes of sanding.

• While holding the sander, grasp the dust collection canister and pull off of the sander.

• Remove the canister door and gently shake or tap the canister and door to empty.

• Re-attach the door and firmly push the canister back onto the sander.

CAUTION: Respiratory hazard. Never operate this tool for wood sanding unless the

dust canister is in place. Sanding dust exhaust may create a breathing hazard.

WARNING: Fire hazard. Collected sanding dust from sanding surface coatings

(polyurethane, linseed oil, etc.) can self-ignite in sander dust canister or elsewhere and cause

fire. To reduce risk, empty canister frequently and strictly follow sander manual and coating

manufacturer's instructions.

WARNING: Fire hazard. When working on metal surfaces, do not use the dust canister or

a vacuum cleaner because sparks are generated. Wear safety glasses and a dust mask. Due

to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet

sanding.

TROUBLESHOOTING

Pr

oblem

Possible

Cause

Possible

Solution

• Unit will not start. • Cord not plugged in. • Plug tool into a working outlet.

• Circuit fuse is blown. • Replace circuit fuse.

(If the product repeatedly

causes the circuit fuse to

blow, discontinue use

immediately and have it

serviced at a Black & Decker

service center or authorized

servicer.)

• Circuit breaker is tripped. • Reset circuit breaker.

(If the product repeatedly

causes the circuit breaker to

trip, discontinue use

immediately and have it

serviced at a Black & Decker

service center or authorized

servicer.)

• Cord or switch is damaged. • Have cord or switch

replaced at Black & Decker

Service Center or Authorized

Servicer.

• Dust is not • Sandpaper holes do not align. • Use Mouse

®

sandpaper

being collected. with the appropriate hole

configuration.

For assistance with your product, visit our website www.blackanddecker.com for the

location of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

Extension Cords

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

Symbols

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min........................minutes ......................alternating current

......................direct current

n

o ........................no load speed

..........................

Class II Construction

........................

earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations per minute

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face and

body.

Safety Warnings and Instructions: Sanders

• ALWAYS USE PROPER EYE AND RESPIRATORY PROTECTION.

• Clean your tool out periodically.

Other Important Safety Warnings and Instructions

Sanding

Lead Based Paint

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is to children and pregnant

women.

Since it is difficult to identify whether or not a paint contains lead without a chemical analysis,

we recommend the following precautions when sanding any paint:

Personal Safety

• No children or pregnant women should enter the work area where the paint sanding is

being done until all clean up is completed.

• A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing.

• NOTE: Only those dust masks suitable for working with lead paint dust and fumes should

be used. Ordinary painting masks do not offer this protection. See your local hardware

dealer for the proper (NIOSH approved) mask.

• NO EATING, DRINKING or SMOKING should be done in the work area to prevent

ingesting contaminated paint particles. Workers should wash and clean up BEFORE

eating, drinking or smoking. Articles of food, drink, or smoking should not be left in the work

area where dust would settle on them.

Environmental Safety

• Paint should be removed in such a manner as to minimize the amount of dust generated.

• Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

• Sanding should be done in a manner to reduce tracking of paint dust outside the work

area.

9

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

5

6

7

8