14.

Disconnect plug from power source

before performing any assembly,

adjustment or repair to avoid possible injury.

Checking Right 45°

Bevel Stop

1. Lower head assembly and engage head assembly

lock pin.

2. Rotate table to the 0° miter position.

3. Pull up bevel lock lever to unlock bevel.

4. Move bevel range selector knob to “0°-45° Right”

position. (See page 26)

5. Tilt the saw to the right until you feel the stop in the

45° right position. This is where the saw is cur-

rently set for the 45° right bevel cut.

6. Use a combination square to check blade at the

45° stop. Place the combination square head on

the table and press it’s 45° surface against the

blade. If the blade does not contact the full length

of the square, (figure 1), follow the calibrating pro-

cedure.

Adjustments (continued)

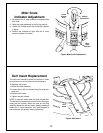

Figure 1. Right 45° Bevel Stop

Figure 2. Right 45° Bevel Adjustment

Calibrating Right 45°

Bevel Stop

1. Lift bevel lock lever to release bevel lock.

2. Tilt saw to 45° right bevel position.

3. Position combination square with 45° surface

against blade. (Figure 1)

4. Insert 3 mm “L” wrench into Right 45° hole in ver-

tical support frame. (Figure 2)

5. Rotate “L” wrench while viewing blade against

combination square until it matches 45° surface.

6. Adjust bevel pointer to 45° line on bevel scale.

3mm “L”

Wrench

in

Right 45°

Access

Hole

Bevel

Pointer

Combination

Square

WARNING

!