-22-

Masonry / Concrete Cutting

With this grinder it is possible to perform

cutting of concrete and masonry materials.

When cutting, work with moderate feed,

adapted to the material being cut.

Always follow precautions for kickback.

Operate the tool with a dust extraction system

and personal dust protection, e.g. respirator,

dust mask, etc. The vacuum used for this

application must be approved for the extraction

of masonry and concrete dust. Bosch sells

suitable vacuum cleaners.

Never pull the tool backward

since blade will climb out of

the material and KICKBACK will occur.

1.Allow the tool to reach full speed before

touching the tool to the work surface.

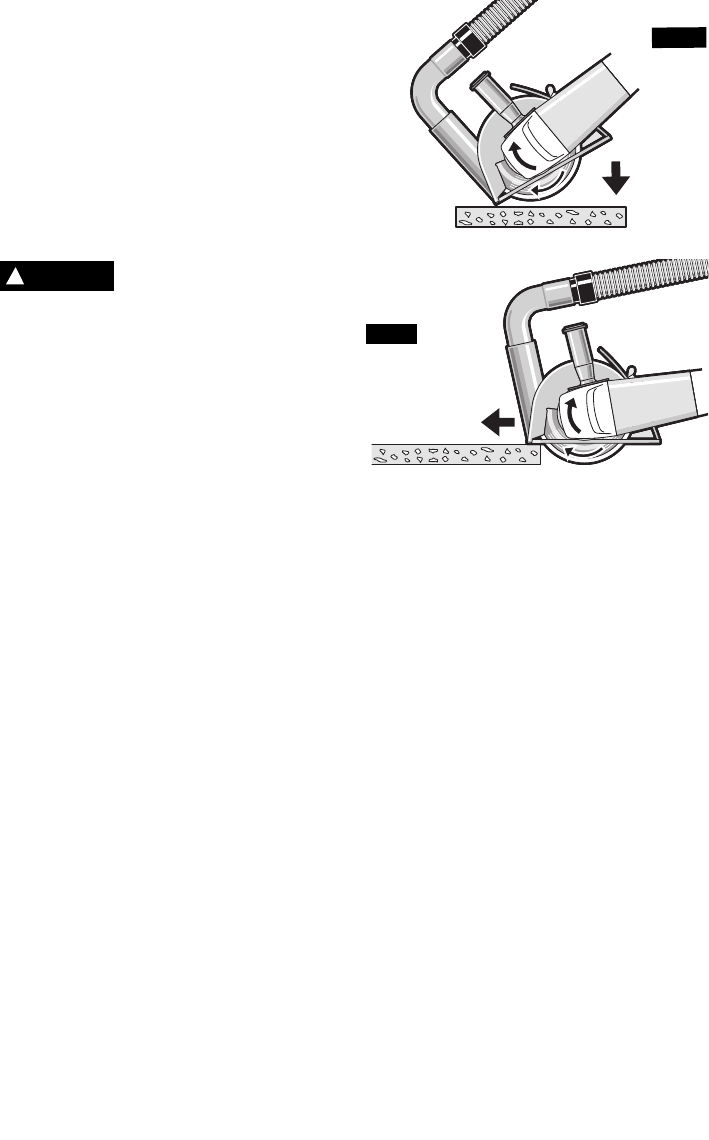

2.If plunge cutting:

a. Tilt tool forward with wheel lined up with

the cut line and hold the tool by the

grinder body and the auxiliary handle

(Fig. 21).

b. Gradually lower the rear of tool using the

front end of the foot as the hinge point.

c. When the foot rests flat on the surface

being cut, proceed cutting in forward

direction to end of cut.

3.Always maintain contact between the guard

foot and work piece.

4.Slide the tool forward at a moderate speed

adapted to the material being cut. Always

cut towards the dust extraction port to

maximize dust extraction and reduce

likelihood of kickback (Fig. 22).

5.Apply minimum pressure to the work

surface, allowing the tool to operate at high

speed. Cutting rate is greatest when the tool

operates at high speed.

6.When the cut is completed, remove tool

from work piece before turning off. Allow

wheel to stop rotating before setting tool

down.

Tip: When performing deep cuts, it is best to

cut in several shallow passes. Each pass

should be only to the segment depth of the

wheel. Masonry dust is abrasive and may

wear and weaken the segment bond.

When cutting especially hard material, e. g.,

concrete with high pebble content, the dry

diamond wheel can overheat and become

damaged. This is clearly indicated by circular

sparking of the rotating dry diamond wheel. In

this case, interrupt the cutting process and

allow the dry diamond wheel to cool by running

the tool for a short period of time at the

maximum speed with no-load.

Noticeable decreasing work progress and

circular sparking are indications of a dry

diamond wheel that has become dull. Briefly

cutting into abrasive materials (e. g. brick) can

resharpen the wheel.

FIG. 22

FIG. 21

!

WARNING