-9-

Operating Instructions

TRIGGER "ON/OFF" SWITCH

Hold the tool with both

hands while starting the

tool, since torque from the motor can

cause the tool to twist.

To turn tool "ON", depress the "Lock-OFF"

button and squeeze the trigger switch. To

turn the tool "OFF", release the trigger

switch which is spring loaded and will return

to "OFF" position automatically.

To increase switch life, do not turn switch on

and off while tool and drum are held against

a workpiece.

BRAKE

When the trigger is released it activates the

electrical brake to stop the blade quickly. This

feature is especially useful when making

repetitive cuts.

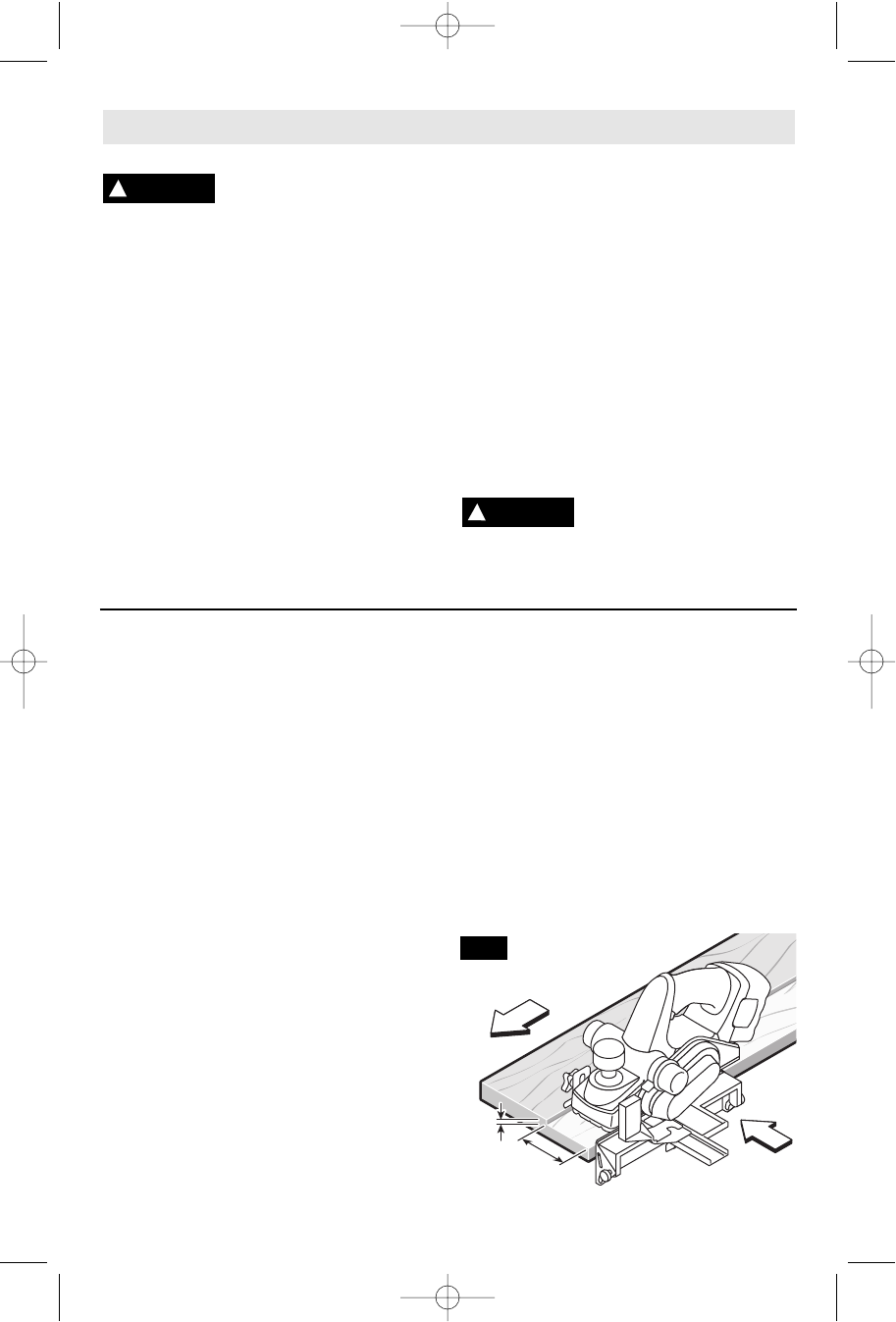

PLANING ACTION

Check that the workpiece is held in place

securely on your work surface, and standing

comfortably, hold the planer firmly with both

hands. With the planer fully adjusted, place

the front shoe on the workpiece, (be certain

that the cutter drum is not in contact with

the work) and start the planer as described

earlier. With pressure on the front shoe, and

the fence against the side of the work (to

control the width or angle,) feed the planer

steadily until the rear shoe fully engages the

workpiece. Now gradually transfer pressure

to the rear shoe, and continue planing to the

end of the cut. Feed the planer at a uniform

and reasonable rate, which does not put

excessive strain on the motor or blades, (do

not pull the planer back over the surface

already cut.) Use progressive cuts until you

are near the desired depth, and then re-

adjust to a light cut for the final pass to

obtain a good surface finish.

The motor may stall if

improperly used or

overloaded. Reduce the pressure (feed

rate) or depth of cut to prevent possible

damage to the tool if the motor labors.

!

CAUTION

ADJUSTING DEPTH OF CUT

Proper cutting depth should be determined

according to the hardness, gumminess or

moisture content of the material being cut,

as well as the feed rate, and is largely a

matter of experience. Start with a light cut

and increase the depth setting if the plane

moves freely through the workpiece with no

excessive load on the motor. Do not change

depth of cut while planing.

The cutting depth is determined by the

difference in height between the adjustable

front shoe, and the fixed rear shoe of the

planer. As the front shoe is adjusted, it

retracts and exposes the blade, which can

then remove the desired amount from the

workpiece. The cutting depth is graduated

from 0 to 1/16 of an inch, and the "0"

indicates the blade is fully retracted.

Adjusting depth of cut: Rotate depth

adjustment knob until the indicator engages

the detent which indicates the desired

cutting depth on the depth scale (Fig. 1).

The planer may be set to cut any depth from

0 to 1/16 of an inch.

STANDARD PARALLEL WIDTH

GUIDE FENCE

The width guide fence can be used to cut

various desired widths (Fig. 1).

Installing the guide fence: Place the wing

knob through the appropriate hole in the

guide bracket and screw into the housing.

Securely tighten wing knob.

Setting the cutting width: Loosen wing knob

and slide the fence along the guide bracket

to the desired position. Securely tighten

wing knob. Be certain that the flat washer

(supplied) is fitted between the bottom of the

guide fence and wing knob or the guide

fence is likely to slip.

DELUXE ANGLE FENCE

The optional deluxe angle fence (Fig. 6) can

be used to cut various desired widths, with

the additional capability of guiding the

!

WARNING

82 mm

max

8 mm

max

FIG. 6

BM 2610917139 6/02 7/10/02 10:50 AM Page 9