6

Operating Instructions

www.chpower.com

User - Maintenance

Instructions

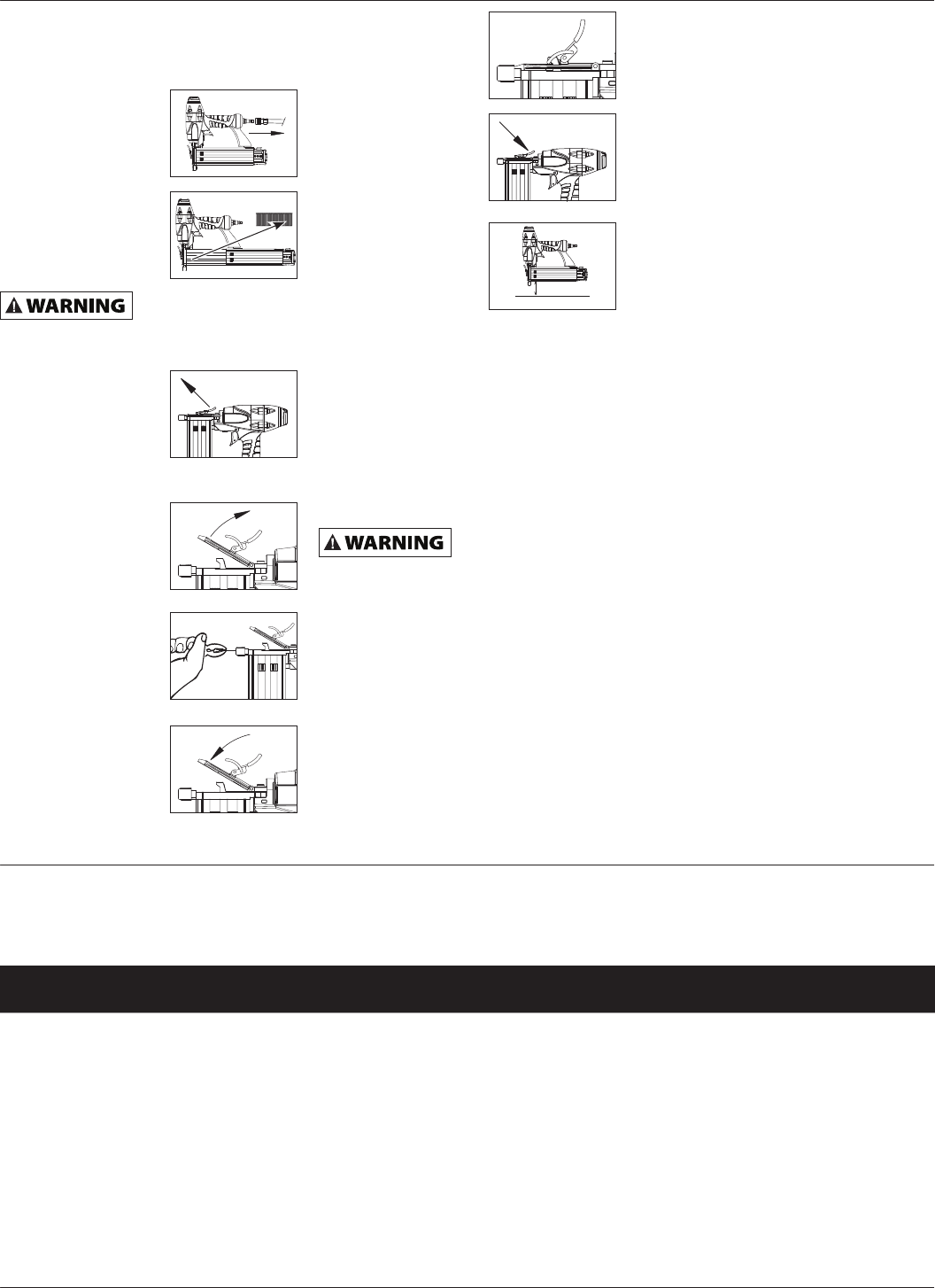

CLEARING A JAM FROM THE TOOL

1. Disconnect the air

supply from the

tool.

2. Remove all nails

from the magazine

(see Loading/

Unloading).

Failure to remove

all fasteners will

cause the fasteners to eject from the

front of the tool.

3. Undo latch by

pulling out

and down. The

wire latch will

disengage from

the hooks on the nose.

4. The door can

now be rotated,

exposing the

jammed fastener.

5. Remove the

jammed fastener,

using pliers or

a screwdriver if

required.

6. Rotate door back

into the closed

position.

7. Extend the wire

latch and place

over the hooks on

the nose.

8. Close the latch by

pushing the latch

up and in until the

latch snaps into

place.

9. Make sure the

trigger and work

contact element

(WCE) move freely

up and down

without sticking or binding.

TECHNICAL SERVICE

Please call our Tool Hotline at 1-800-

543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual.

FASTENER AND REPLACEMENT

PARTS

Use only headless

micropins, 18 gauge.

Tool performance, safety and durability

could be reduced if improper fasteners

are used. When ordering replacement

parts or fasteners, specify by part

number.

TOOL REPAIR

Only qualified personnel should repair

the tool and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently.

ASSEMBLY PROCEDURE FOR SEALS

When repairing a tool, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W

non-detergent oil or equivalent, must

be added through the air line before

testing.

STORAGE

The tool should be stored in a cool dry

place.

Fasteners

The following Campbell Hausfeld finishing nails are available at local retail stores. If you need help locating any item, call

customer service at 1-800-543-6400. Campbell Hausfeld nails meet or exceed ASTM Standard F1667.

Model Length

Shank

Gauge Finish Head Collation

Nails Per

Stick

Nails Per

Box

FB002000 3/4 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 5000

FB180016 5/8 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180025 1 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180030 1-1/4 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180040 1-1/2 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180050 2 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

Interchange Information

Can use brad nails from the following branded air-powered brad nailers: Bostitch

®

BT125SK-2 & BT200K-2, Campbell

Hausfeld

®

NB0030 & NB0040, DeWalt

®

D51238K, Paslode

®

T125-F18 & T200-F18, Porter Cable

®

BN125 & BN200, and

Senco Finish Pro

®

15 & 18.