Operating The

Stapler (Continued)

2. An oiler can be

used to provide oil

circulation through

the tool. A filter

can be used to

remove liquid and

solid impurities which can rust or

“gum up” internal parts of the tool.

3. Always use air supply hoses with a

minimum working pressure rating

equal to or greater than the pres-

sure from the power source if a reg-

ulator fails, or 150 psi, whichever is

greater. Use 3/8” air hose for runs

up to 50’. Use 1/2” air hoses for 50’

run or longer. For better perfor-

mance, install a 3/8” quick plug

(1/4” NPT threads) with an inside

diameter of .315” (8mm) on the

tool and a 3/8” quick coupler on the

air hose.

4. Use a pressure regulator on the

compressor, with an operating pres-

sure of 0 - 125 psi. A pressure regu-

lator is required to control the oper-

ating pressure of the tool between

60 and 100 psi.

OPERATIONAL MODE

Always know the

operational mode

of the tool before using. Failure to

know the operational mode could

result in death or serious personal

injury.

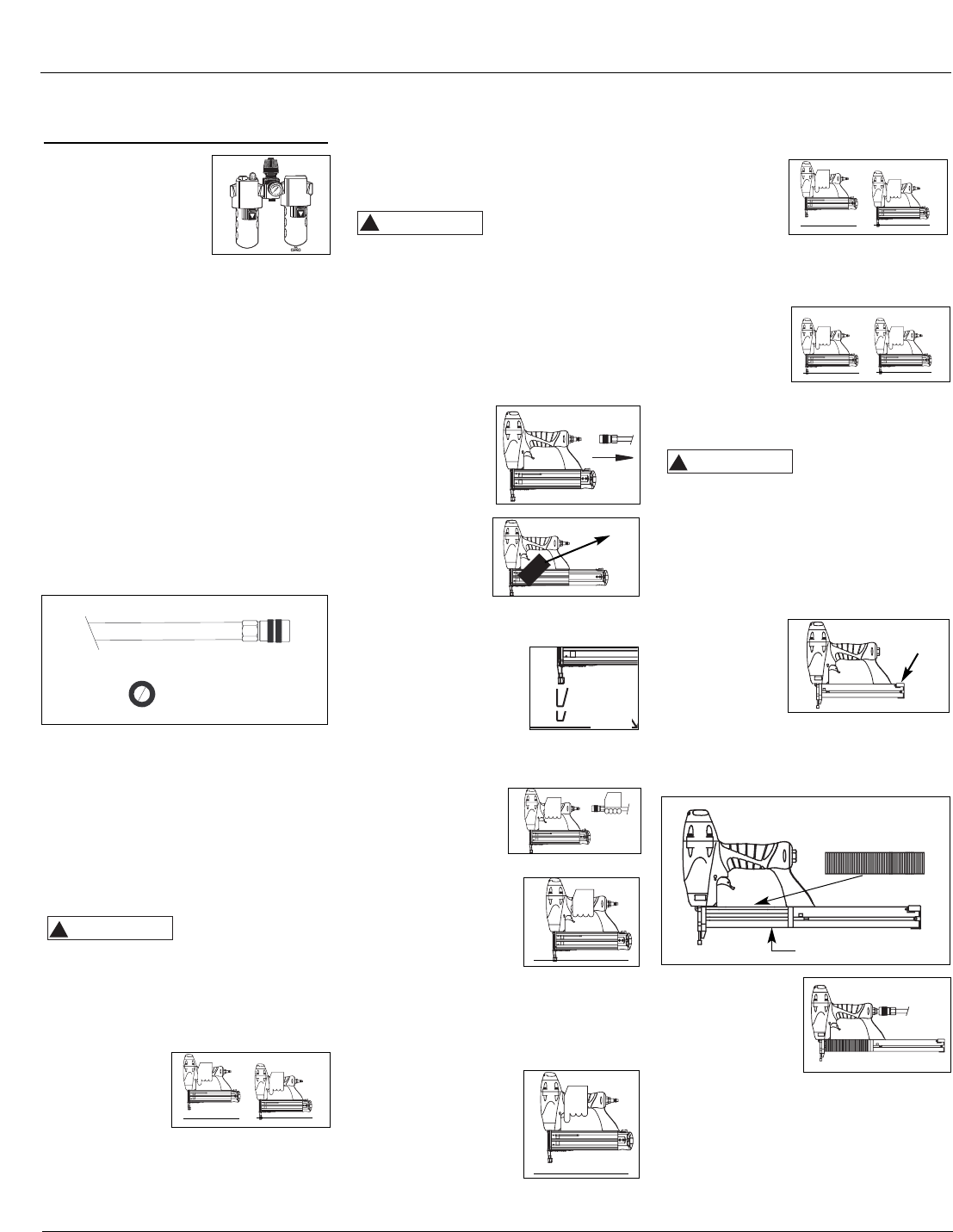

SINGLE SEQUENTIAL MODE

This mode

requires the trig-

ger to be pulled

each time a fas-

tener is driven. The tool can be actuat-

ed by depressing the Work Contact

Element (WCE) against the work sur-

face followed by pulling the trigger.

!

WARNING

OPERATE. Do not use the tool if it

operates while lifted from the work

surface. Personal injury may result.

7. Pull the trig-

ger and

depress the

work contact

element (WCE) against the work

surface. The tool MUST NOT OPER-

ATE.

8. Depress the

Work Contact

Element

(WCE) against

the work surface. Pull the trigger.

The tool MUST OPERATE.

An improperly

functioning tool

must not be used. Do not actuate the

tool unless the tool is placed firmly

against the work piece.

LOADING/UNLOADING THE TOOL

1. Always connect the tool to the air

supply before loading fasteners.

2. Push down

on the latch

button. Pull

back on the

magazine

cover.

3. Load a clip of fasteners with the

crowns straddling the magazine rail.

4. Push the maga-

zine cover for-

ward until latch

button pops

up.

5. Always unload all fasteners before

removing tool from service.

Unloading is the reverse of loading,

except always disconnect the air

supply before unloading.

!

WARNING

The trigger must be released to reset

the tool before another fastener can be

driven.

OPERATING A SEQUENTIAL TRIP

TOOL

Check the opera-

tion of the Work

Contact Element (WCE) trip mechanism

before each use. The WCE must move

freely without binding through its

entire travel distance. The WCE spring

must return the WCE to its fully extend-

ed position after being depressed. Do

not operate the tool if the WCE trip

mechanism is not operating properly.

Personal injury may occur.

1. Disconnect the

air supply from

the tool.

2. Remove all fas-

teners from the

magazine (see

Loading/

Unloading).

3. Make sure the trig-

ger and work con-

tact element (WCE)

move freely up and

down without stick-

ing or binding.

4. Reconnect air

supply to the

tool.

5. Depress the Work

Contact Element

(WCE) against the

work surface with-

out pulling the trig-

ger. The tool MUST NOT OPERATE.

Do not use the tool if it operates

without pulling the trigger.

Personal injury may result.

6. Remove the tool

from the work sur-

face. The Work

Contact Element

(WCE) must return

to its original down

position. The tool MUST NOT

!

CAUTION

CHN10302

Operating Instructions

4

www.chpower.com

movement

150 psi or greater

3/8” I.D.

1

2

1

2

Latch

Button

Magazine rail