Operating Instructions Gravity Feed Spray Gun

6

www.chpower.com

User - Maintenance

Instructions (Continued)

4. Check and replace any damaged

o-rings and seals. O-rings and seals

can be wiped clean but not soaked

in solvent.

5. Unscrew packing nuts and replace

the packing ONLY if a leak will not

stop when the nut is tightened (See

Figure 5). Do not over-tighten a

packing nut because this will restrict

movement of the needle.

6. Re-assemble in reverse order of

above and use a non-silicone oil on

moving parts. Apply Vaseline® or

light grease on threaded joints and

hose connections.

TECHNICAL SERVICE

Please call our Tool Hotline at 1-800-

543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual.

TOOL REPAIR

Only qualified personnel should repair

the tool and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently.

STORAGE

1. When not using spray gun,

turn the fluid adjustment knob

counterclockwise to open which

will reduce spring tension on needle

fluid tip.

2. Spray gun MUST BE well cleaned

and lightly lubricated.

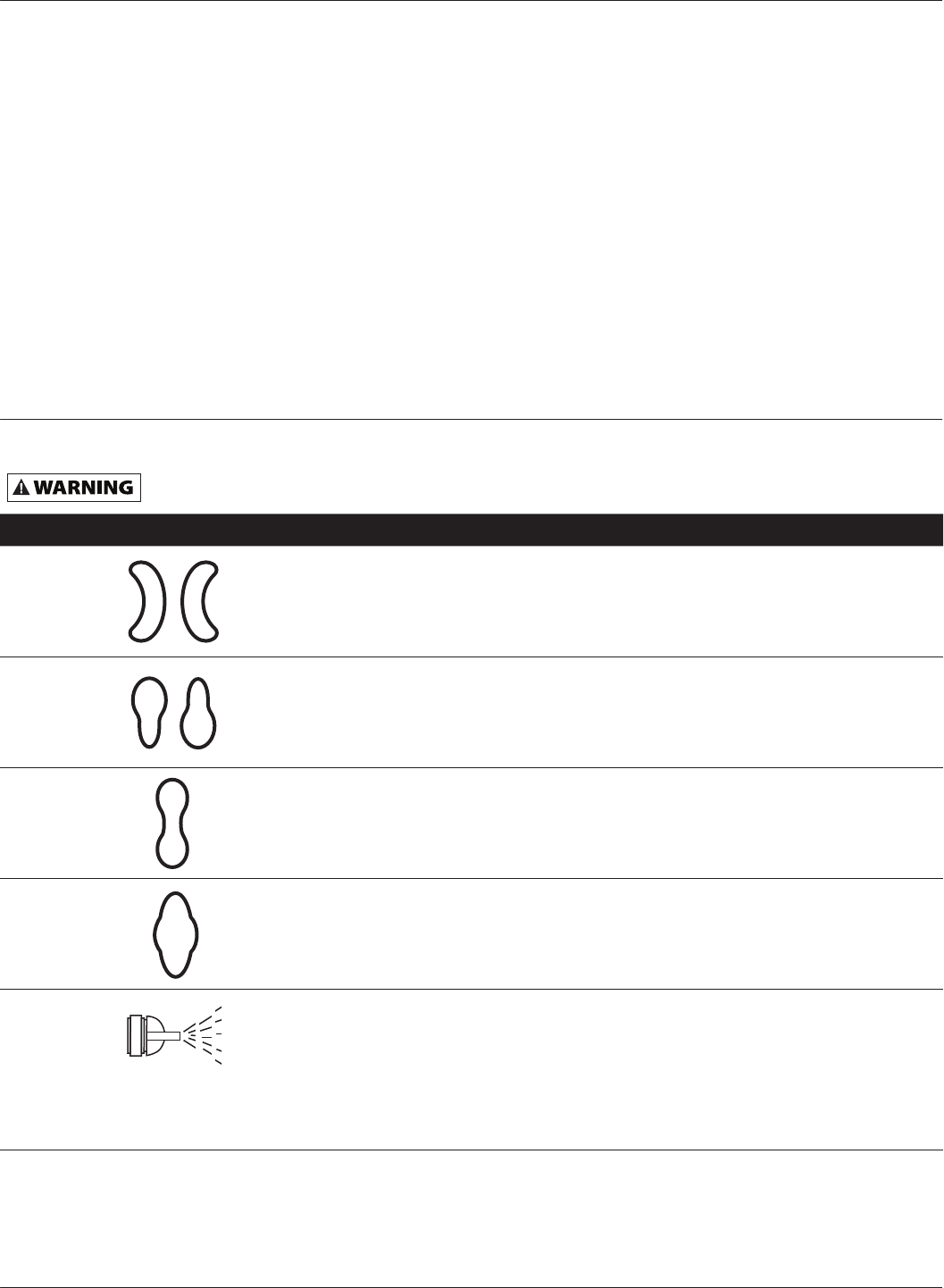

Troubleshooting Chart

Stop using tool immediately if any of the following problems occur. Serious personal injury could occur.

Any repairs or replacements must be done by a Qualified Service Person or Authorized Service Center.

Symptom Possible Cause(s) Corrective Action

Right or left

heavy spray

pattern

1. Holes in left or right side of the air cap

are plugged

1. Clean. Use only non-metallic pick

2. Dirt on left or right side of fluid tip 2. Clean

Top or

bottom

heavy spray

pattern

1. Dried material at top or bottom of fluid

tip

1. Clean

2. Loose air cap or dirty seat 2. Clean and tighten

3. Air cap plugged 3. Clean. Use only non-metallic pick

Split spray

pattern

1. Fan pattern open too far 1. Partially close the pattern adjustment

2. Fluid turned in too far 2. Increase fluid

3. Atomization air too high 3. Reduce atomization air pressure

Center

heavy spray

pattern

1. Fan adjustment partially closed 1. Open fan pattern adjustment

2. Material too thick 2. Thin to proper viscosity

3. Atomization pressure too low 3. Increase atomization pressure

Sputtering

spray

1. Material level too low 1. Refill

2. Container tipped too far 2. Hold more upright

3. Loose fluid inlet connection 3. Tighten

4. Loose or damaged fluid tip / seat 4. Adjust or replace

5. Dry or loose fluid needle packing nut 5. Lubricate and or tighten

6. Air vent clogged 6. Clear vent hole

Fluid leaking from packing

nut

1. Packing nut loose 1. Tighten, but do not restrict needle

2. Packing worn or dry 2. Replace or lubricate (non-silicone oil)