6

Rote la puerta

hacia atrás a la

posición cerrada.

7. Extienda el

pestillo de alam-

bre y colóquelo

sobre los gan-

chos de la

boquilla.

8. Cierre el pestillo

empujándolo

hacia adentro

hasta que ajuste

en su posición.

9. Asegúrese que

el gatillo y el

Elemento de

Contacto de

Trabajo se

mueven libre-

mente, hacia arriba y hacia abajo sin

pegarse o atascarse.

4. Use a pressure regulator on the

compressor, with an operating pres-

sure of 0 -125 psi. A pressure regu-

lator is required to control the

operating pressure of the nailer

between 70 and 120 psi.

Sequential Trip Safety

Mechanism

The tool is equipped with a sequential

trip safety mechanism. When the oper-

ator depresses the Work Contact

Element (WCE) against the work sur-

face and then pulls the trigger, a fas-

tener will be driven.

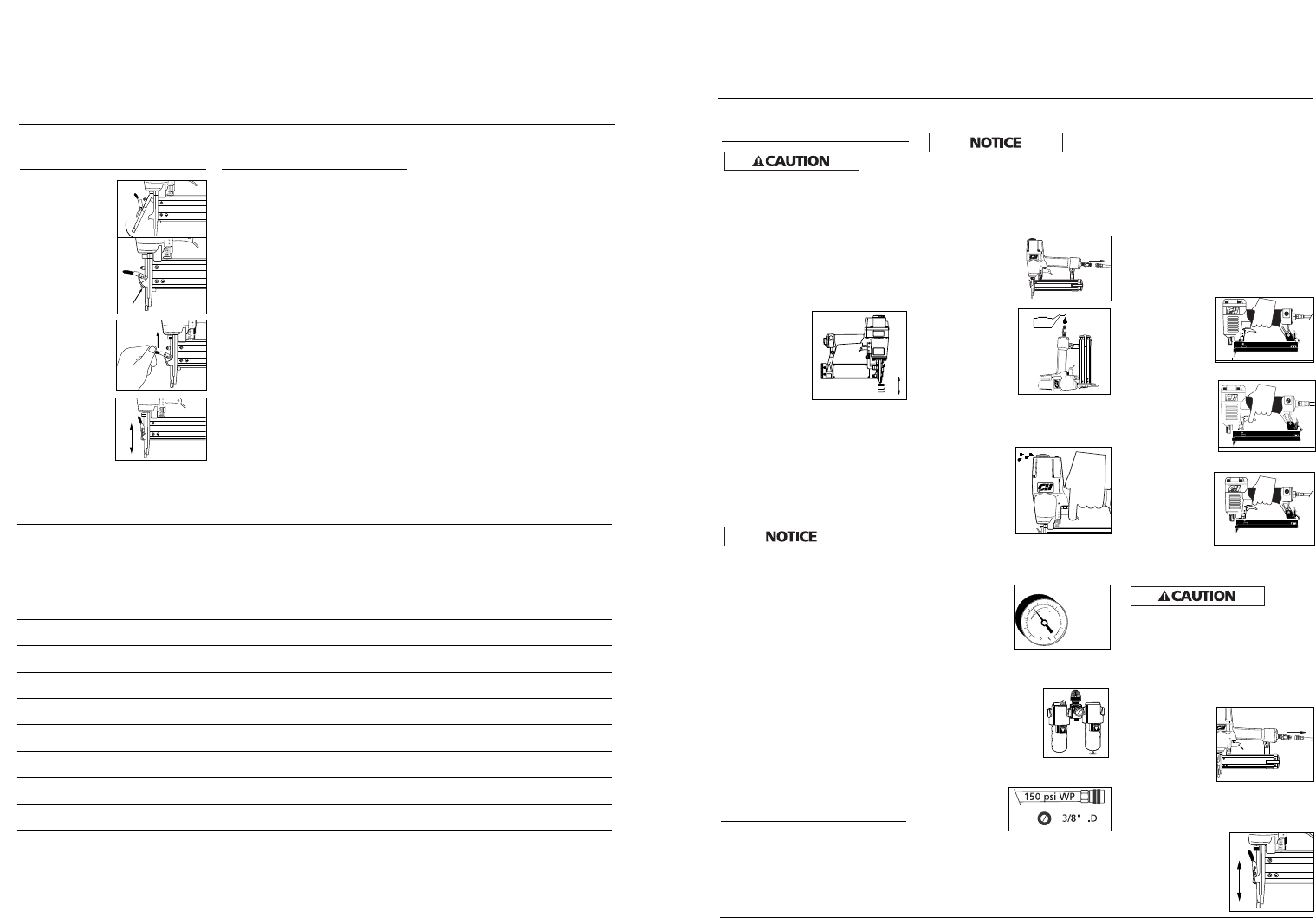

OPERATING A SEQUENTIAL TRIP

TOOL

1. Release trig-

ger and place

nose of tool

against work

surface.

2. Depress the

Work contact

element (WCE)

against the

work surface

and pull the

trigger to drive

a fastener.

3. Release the

trigger and lift

the tool from

the work sur-

face after

each fastener

is driven.

CHECKING THE WORK CONTACT

ELEMENT (WCE)

Check the

opertion

of the Work Contact Element (WCE) trip

mechanism before each use. The WCE

must move freely without binding

through its entire travel distance. The

WCE spring must return the WCE to its

fully extended position after being

depressed. Do not operate the nailer if

the WCE trip mechanism is not operating

properly. Personal injury may occur.

1. Disconnect the

air supply from

the nailer.

2. Remove all nails from the magazine

(see Loading/ Unloading The Nailer).

3.

Make sure the trig-

ger and work con-

tact element (WCE)

move freely up and

down without

sticking or binding.

used, manual lubrication through the

air inlet is not required on a daily basis.

The work

surface

can become damaged by excessive

lubrication. Proper lubrication is the

owner’s responsibil- ity. Failure to

lubricate the nailer properly will dra-

matically shorten the life of the nailer

and void the warranty.

1. Disconnect the

air supply from

the nailer to

add lubricant.

2. Turn the nailer

so the air inlet

is facing up.

Place 4-5 drops

of 30 W non-

detergent oil

into air inlet.

Do not use

detergent oils,

oil additives, or air tool oils. Air tool

oils contain solvents which will

damage the nailer's internal com-

ponents.

3. After adding

oil, run nailer

briefly. Wipe

off any excess

oil from the

cap exhaust.

RECOMMENDED HOOKUP

Please refer to Airtool Setup

(IN170102AV) for system hookup

instructions.

1. The air com-

pressor must

be able to

maintain a

minimum of

70 psi when

the nailer is being used. An inade-

quate air supply can cause a loss of

power and inconsistent driving.

2. An oiler can be used

to provide oil circula-

tion through the

nailer. A filter can

be used to remove

liquid and solid

impurities which can

rust or “gum up” internal parts of

the nailer.

3. Use 3/8” air

hoses with a

minimum

working pres-

sure of 150

psi. Use 1/2” air hoses for 50’ run or

longer. For better performance,

install a 3/8” quick plug (1/4” NPT

threads) with an inside diameter of

.315" (8mm) on the nailer and a

3/8” quick coupler on the air hose.

Caution

indicates

a potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

● Do not make any modifications to the

tool without first obtaining written

approval from Campbell Hausfeld. Do

not use the tool if any shields or

guards are removed or altered. Do

not use the tool as a hammer.

Personal injury or tool

damage may occur.

● Always check

that the Work

Contact

Element (WCE)

is operating

properly. A fas-

tener could

accidentally be

driven if the WCE is not working

properly. Personal injury may occur

(See "Checking the Work Contact

Element" Section).

● Disconnect air supply and release

tension from the pusher before

attempting to clear jams because

tools can be ejected from the front

of the tool. Personal injury may

occur.

Notice

indicates

important information, that if not fol-

lowed, MAY cause damage to equipment.

● Avoid using the tool when the mag-

azine is empty. Accelerated wear on

the tool may occur.

● Clean and check all air supply hoses

and fittings before connecting the

tool to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

● Air compressors providing air to the

tool should follow the requirements

established by the American

National Standards Institute

Standard B19.3-1991; Safety

Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for

information.

Operating The Nailer

Read this manual and understand all

safety warnings and instructions before

operating the nailer.

LUBRICATION

This nailer requires lubrication before

using the nailer for the first time and

before each use. If an inline oiler is

3

OIL

70 psi

Min.

120 psi

Max.

Model NB004100

Operating Instructions

www.chpower.com

Modelo NB004100

Manual de Instrucciones

5 Sp

Servicio Técnico

Si desea hacer alguna pregunta refer-

ente a la reparación u operación de las

clavadoras, sírvase llamar a nuestro

número especial, 1-800-543-6400.

Clavos et Repuestos

Use solamente sujetadores Campbell

Hausfeld originales calibre 16 (o su

equivalente) - (vea la información sobre

intercambio de sujetadores). Use sola-

mente partes de repuesto Campbell

Hausfeld originales. Nunca substituya

las partes. No use partes modificadas o

partes que no den un rendimiento

equivalente al equipo original. El

rendimiento de las herramientas, la

seguridad y la duración pueden verse

reducidos. Cuando ordene partes de

repuesto o sujetadores, especifique el

número de la parte.

Para reparar la clavadora

Las reparaciones de la clavadora las

debe hacer SOLAMENTE un técnico cali-

ficado que tenga experiencia.

Para colocarle los sellos

Cada vez que repare una clavadora

deberá limpiarle y lubricarle las partes

internas. Le recomendamos que use

Parker O-lube o un lubricante equiva-

lente en todos los anillos en O. A cada

anillo en O se le debe dar un baño de

lubricante para anillos antes de insta-

larlos. Igualmente, deberá ponerle un

poco de aceite a todas las piezas que se

mueven y muñones. Finalmente,

después de haberla ensamblado y antes

de probar la herramienta deberá pon-

erle unas cuantas gotas de aceite sin

detergente 30W u otro aceite similar,

en las líneas de aire.

Notas

General Safety

Information (Continued)

Cómo Usar la

Clavadora (Continuación)

Mantenimiento