7. Turn on the welder and activate the

gun switch until the wire feeds out

past the torch end. Turn welder off.

8. Carefully slip the contact tip over the

wire and screw it into the torch end.

Install the nozzle by turning

clockwise. (See Figure 5). Cut the

wire off approximately 1/4 inch from

the end of the nozzle.

Assembly - WF2000

All welding accessories for the

welder are inside the wire feed

compartment. Lift and remove wire

feed cover to find handle,

workclamp, etc.

Handle Assembly

1. Slide handle into plastic ends as

shown (Fig. 6).

2. Place handle assembly on welder

aligning two holes in plastic ends

with threaded holes in welder

housing.

3. Fasten screws through handle ends

and into cabinet.

WORK CLAMP

1. Loosen hex bolt on work clamp.

2. Insert cord (labeled work on the

front panel of the welder) through

clamp handle and slide bare wire

under the clamp block. Tighten hex

bolt making sure bare wire is

clamped securely (Fig. 7).

4

Operating Instructions and Parts Manual

Assembly - WF1800/

WF1900 (Continued)

Any mismatch could cause the wire to

slip, bind or weld poorly.

1. Verify the unit is off and lift the

panel on the welder to expose the

wire feed mechanism.

2. Loosen the wire feed tensioning

screw on the drive mechanism. This

allows initial feeding of the wire into

the gun liner by hand.

3. Install the wire spool onto the

spindle so that the wire can come off

the spool on the end closest to the

wire feed guide tube. Do not cut

the wire loose yet.

4. Hold the wire and cut the wire end

from the spool. Do not allow the

wire to unravel. Be sure that the end

of the wire is straight and free of

burrs.

5. Feed the wire through the wire feed

guide tube, over the groove in the

drive roll and into the gun liner.

Tighten the wire feed tensioning

screw so that it is snug. Do not over

tighten. Close the wire feed panel.

6. Remove the nozzle by turning

counter-clockwise. Then unscrew the

contact tip from the end of the

welding torch (See Figure 5). Plug

the welder into the proper power

supply receptacle.

Flux Core Wire Installation

Welding power

may be applied to

the output terminals, feed roll, work

clamp, gun cable connection and welding

wire even when the the gun switch is not

activated. Do not touch these parts when

the welding machine is on.

Note: Before installing welding wire, be

sure that the diameter of the welding

wire matches the groove in the drive

roller on the wire feed mechanism and

that the wire size matches the contact

tip in the end of the gun (see Figure 5).

Any mismatch could cause the wire to

slip, bind or weld poorly.

1. Verify the unit is off and lift the

panel on the welder to expose the

wire feed mechanism.

2. Remove the spool quick lock by

pushing in and rotating 1/4 turn

counterclockwise. The knob, spring,

and spool spacer can now be

removed.

3. Loosen the wire feed tensioning

screw on the drive mechanism. This

allows initial feeding of the wire into

the gun liner by hand.

4. Install the wire spool onto the

spindle so that the wire can come off

!

WARNING

Wire Flux

Core

Pan Head Screws

Swing

Arm

Tension

Screw

Tension

Spring

Spindle

Roller

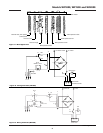

Figure 4 - Weld Wire Routing

Contact Tip Markings

Mark Wire Size

0.8 0.030”

0.9 0.035”

1

1

5

V

O

L

T

G

R

O

U

N

D

6

0

H

Z

2

3

A

0

1

2

3

4

5

6

7

8

9

1

0

N

O

R

M

A

L

O

P

E

R

A

T

I

N

G

R

A

N

G

E

S

I

N

G

L

E

P

H

A

S

E

WF2000

O

N

O

F

F

L

O

W

H

I

G

H

H

E

A

T

S

E

L

E

C

T

O

R

W

I

R

E

S

P

E

E

D

L

O

W

5

5

A

C

1

7

2

5

%

4

2

H

I

G

H

6

5

A

C

1

8

2

0

%

4

4

H

E

A

T

S

E

T

T

I

N

G

W

E

L

D

I

N

G

A

M

P

S

W

E

L

D

I

N

G

V

O

L

T

S

D

U

T

Y

C

Y

C

L

E

M

A

X

O

C

V

Figure 6 - Handle Assembly

Figure 7 - Work Clamp Assembly

Contact Tip Markings

Mark Wire Size

0.8 0.030”

0.9 0.035”

Wire Size Chart

Inches mm

0.030 0.8

0.035 0.9

Wire Size Chart

Inches mm

0.030 0.8

0.035 0.9

Drive

Roller

Spool

Lock

Tension

Screw

Panel

Spring

Figure 8 - Weld Wire Routing

Spool

Spacer

Spindle

Guide

Tube

www.chpower.com

Torch

Diffuser

Contact Tip

Nozzle

Figure 5 - Torch Nozzle