5

WG3013

if the duty cycle is exceeded. Welding

operations may continue when the

yellow lamp is no longer illuminated.

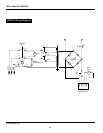

1. Cut retainer stiffeners and

detachable handle away from shield.

Trim the excess plastic to remove

sharp edges.

2. Insert filter lens.

3. Attach the stiffeners over the pins on

the lens retainers (See Figure 6).

4. To attach the handle, place shield on

a flat surface and press handle into

place (See Figure 7).

NOTE: If you have never welded

before or have little experience, a

full face helmet is recommended.

Both hands are needed to stabilize

and control the angle and arc

length of the torch.

Improper handling

and maintenance

of compressed gas cylinders and

regulators can result in serious injury

!

DANGER

or death! Always secure gas cylinders

to the tank bracket kit, a wall or other

fixed support to prevent the cylinder

from falling over. Read, understand,

and follow all the compressed gases

and equipment hazards in the safety

instructions.

NOTE: Shielding gas is not required if

flux-cored welding wire is used.

GAS TYPES

There are 3 types of gas generally used

for gas metal arc welding; 100% argon,

a mixture of 75% argon and 25%

carbon dioxide (C25) or 100% carbon

dioxide. However, 100% carbon

dioxide is not recommended due to

unsatisfactory weld beads. This welder

does not perform well with 100%

carbon dioxide. The 75/25 mixture is

recommended for general steel

welding. For aluminum welding, use

100% argon. Cylinders of either type

gas may be obtained at your local

welding supply outlet. Secure cylinder

in place on your welding machine or

other support to prevent the cylinder

from falling over.

NOTE: Use of incorrect gas may lead to

little or no penetration of welding

bead.

REGULATOR (NOT INCLUDED)

The regulator provides a constant

shielding gas pressure and flow rate

during the welding process.

HOOKUP PROCEDURE

Cylinder gas is

under high

pressure. Point cylinder outlet away

from yourself and any bystanders

before opening.

1. These units fit a 20 cubic ft bottle.

2. With the cylinder securely installed,

remove the cylinder cap, stand to the

side of the cylinder opposite the

outlet, and open the valve slightly,

turning counterclockwise. When gas

is emitted from the cylinder, close the

valve by turning clockwise. This will

blow out dust or dirt that may have

accumulated around the valve seat.

3. Install the regulator onto the

cylinder valve, keeping the face of

the gauges in the vertical position

and tighten the stem nut securely

to the gas valve.

4. Install one end of the gas hose (not

included) to the fitting on the rear

of the welder and the other end to

the fitting on the regulator using

hose clamps (not included) on each

!

WARNING

connection. Make sure the gas hose

is not kinked or twisted.

5. Once again, stand opposite the

cylinder outlet and slowly open the

cylinder valve. Inspect for leaks in

the connections.

6. Pull the trigger on the gun to allow

the gas to flow. While the trigger is

pulled and gas is flowing, adjust the

gas regulator to 30-35 cfh (cubic

feet per hour). Release the trigger.

7. Remember to close the gas valve

when finished welding.

1. Be sure to read,

understand, and comply

with all precautions in

the General Safety

Information section. Be

sure to read the entire section

entitled Welding Guidelines prior to

using this equipment.

2. Verify welder is off.

3. Verify that the surfaces of metals to

be joined are free from dirt, rust,

paint, oil, scale or other contam-

inants. These contaminants make

welding difficult and cause poor

welds.

All persons operating this

equipment or in the area

while equipment is in use

must wear protective welding gear

including: eye protection with proper

shade, flame resistant clothing, leather

welding gloves, and full foot

protection.

WHETHER OR

NOT THE TRIGGER

IS PULLED, the welding wire is LIVE

whenever the welder is turned ON.

If heating, welding, or

cutting materials that are

galvanized, zinc plated, lead,

or cadmium plated refer to the General

Safety Information Section for

instructions. Extremely toxic fumes are

created when these metals are heated.

4. Connect the work clamp to the

work piece or workbench (if metal).

Make sure the contact is secure.

Avoid surfaces with paint, varnish,

corrosion, or non-metallic materials.

5. Position the Heat Selector on the

front panel to the desired setting.

!

WARNING

!

CAUTION

!

DANGER

Assembly

(Continued)

Shielding Gas

Installation

Handshield

Assembly

Figure 6

Lens

Lens

Retainer

Retainer

Stiffener

Figure 7

www.chpower.com

Operation

MANUAL