Page 5SKU 3223

For technical questions, please call 1-800-444-3353.

Operation

Note: Before trying to pull out a dent on your vehicle, it is recommended that you first practice

welding to a scrap of metal. Also practice pulling out the dent with the Slide Hammer.

Clean the surface down to the metal where the stud is to be welded.

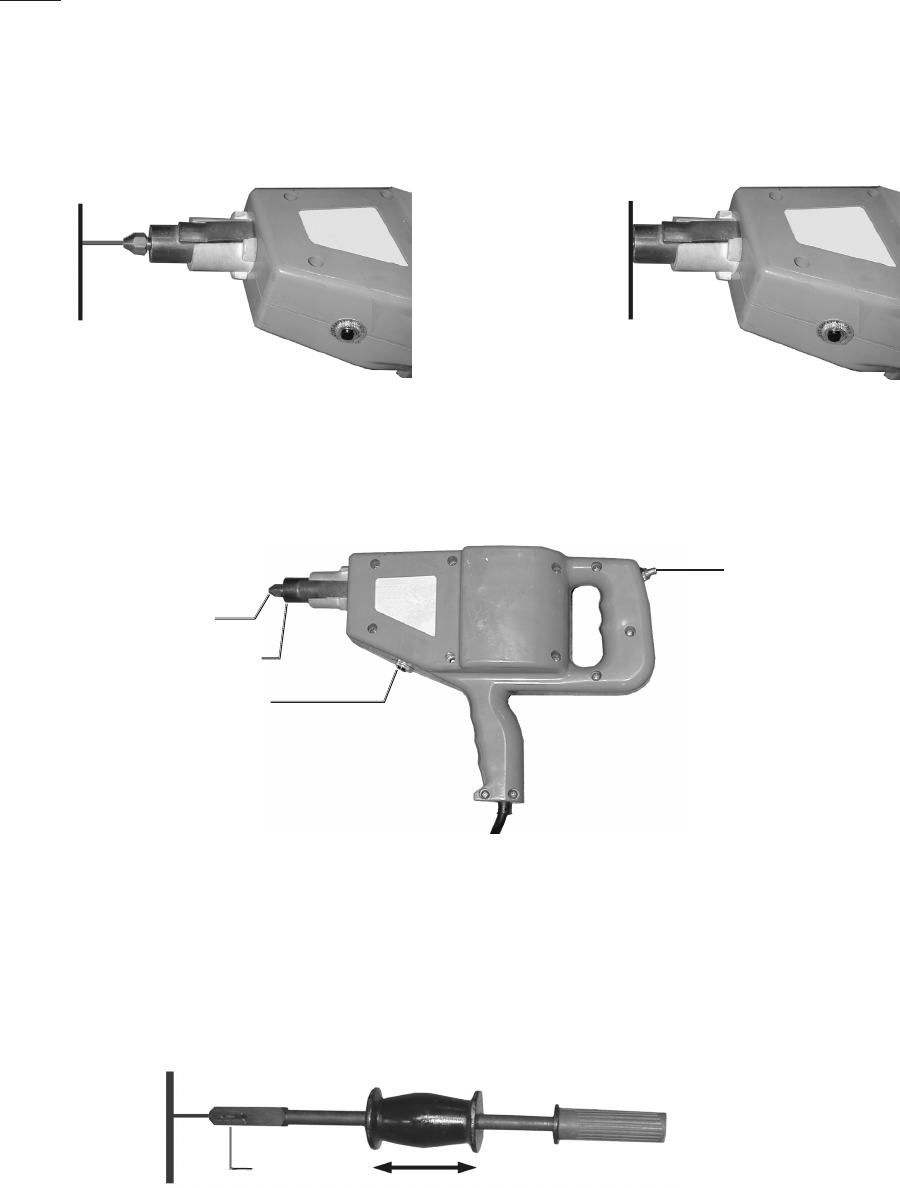

Insert the stud into the hole of the Stud Electrode.

Plug the Line Cord into an electrical circuit outlet with at least a 20 amp capacity.

With sure footing, and both hands on the Stud Welder, push the Stud Welder toward

the metal surface until the Electrode Assembly touches the metal surface.

While holding the Stud Welder steady, press in on the Trigger Switch momentarily from

0.5 to 1 second. Release the Trigger Switch.

Trigger Switch

Circuit Breaker Reset

Stud Electrode

Electrode Assembly

Pull the Stud Welder directly back, leaving the welded stud in place. There should be

less than 1/4 inch discoloration around the weld.

Place and tighten the Slide Hammer head onto the welded stud by turning the head

roller toward you to the top of its rotation and slide the tip over the stud to be pulled.

With one hand on the (center) handle, and the other hand on the back handle, apply a

backward hammering motion to the desired pressure until the dent has popped out.

Back Handle

Head Roller

Disengage the Slide Hammer head from the welded stud by tapping the (center) handle

forward on the head until the Stud is released.

10. Cut off stud and grind down the stud tip to the metal surface.

1.

2.

3.

4.

5.

6.

7.

8.

9.