SKU 98759 For technical questions, please call 1-800-444-3353. Page 8

for the job onto the end of the Spot

Insert one of the included electrodes 6.

Clamp the electrode holder of the 7.

ARC welder onto the Connection (15)

of the Spot Welder.

Adjust the output to no greater than 8.

50 Amps.

9. DANGER! To prevent serious

injury and death. If the operator

is not holding the Spot Welder, it

must be sitting on a nonconduc-

tive, nonammable surface. The

Spot Welder will immediately

turn on when the power button

is turned on. The connection be-

tween the Spot Welder and the

electrode clamp of the ARC welder

must also be must be sitting on

a nonconductive, nonammable

surface.

Turn on the ARC welder. 10.

Pull the Trigger all the way back and 11.

touch the prongs to the workpiece.

Release the trigger slowly until it 12.

connects the workpiece, then pull the

trigger back about 1/16”. The arc will

be ignited. The weld should take two

to three seconds to complete.

Pull the trigger all the way back to 13.

break the arc.

Allow the Spot Welder to cool down 14.

after ten welds.

15.

trode from the workpiece, discharge

the electrode to ground and turn the

Welder off. Disconnect the Spot

Welder from its power source.

Place the Spot Welder down on a 16.

-

face to cool.

To prevent accidents, disconnect the 17.

Spot Welder from the ARC welder

after use. Clean, then store the tool

indoors out of children’s reach.

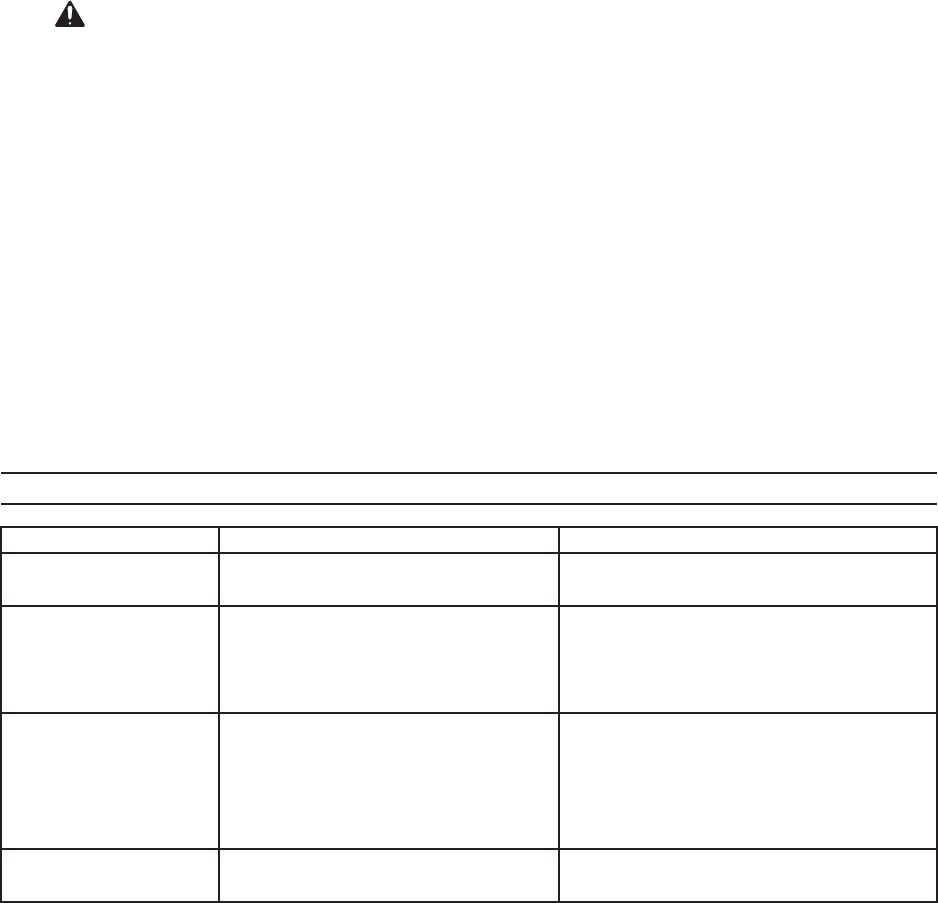

TROUBLESHOOTING

Symptom Cause Solution

Weld does not occur. Unit not plugged in.1.

Blown fuse or circuit breaker.2.

Plug Power Cord into electrical outlet.1.

Replace fuse or reset circuit breaker.2.

Weld not strong/deep

enough.

Electrode dirty or oxidized.1.

Poor contact with metals.2.

Electrode holder dirty or oxidized.3.

Clean or replace Electrode. 1.

Press harder against workpiece/.2.

Clean area with copper cleaner and 3.

weld time required.

Metals to be welded are dirty. 1.

Electrode dirty, oxidized, or pitted.2.

Nuts on Conductors loose.3.

Facility line voltage low.4.

1.

sandpaper.

Clean, resurface, or replace Electrode.2.

Tighten nuts.3.

Check line voltage with voltmeter.4.

Burn through at weld

point.

Weld time too long.1.

Electrode dirty, oxidized, or pitted.2.

Shorten weld time.1.

Clean, resurface, or replace Electrode.2.

REV 09c