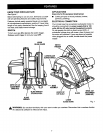

TO POCKET CUT

See Figure 20.

,_ WARNING: Always adjust bevel setting to zero

before making a pocket cut. Attempting a pocket

cut at any other settingcan result in loss ofcontrol

of your saw possiblycausing serious injury.

Adjust the bevel setting to zero, set blade to correct

blade depth setting, and swing the lower blade guard

up using the lower blade guard handle.

Always raise the lower blade guard with the

handle to avoid serious injury.

While holding lower blade guard by the handle, firmly

rest the front of the base flat against the workpiece

with the rear of the handle raised so the blade does

not touch the workpiece. See Figure 20.

LOWER

BLADEGUARD

POCKETCUT

LOWERBLADE

GUARDHANDLE Fig. 20

Squeeze the switch trigger to start your saw. Always

let the blade reach full speed then slowly lower

blade Into the workplece until base is flat against

workpleee.

After you complete your cut release the trigger and

allow the blade to come to a complete stop. After the

blade has stopped, remove it from the workpiece.

Corners may then be cleared out with a hand saw or

sabre saw.

_ WARNING: Never tie the lower blade guard in a

raised position. Leaving the blade exposed could

lead to serious injury.

TO RIP CUT

OPTIONAL RIP GUIDE (EDGE GUIDE)

See Figure 21.

Use a guide when making long or wide rip cuts with

your saw. An optional rip guide with a five inch scale is

available at your Sears Retail Store or you can make

an efficient rip guide by clamping a straight edge to

your workpiece. Secure the workpiece. Using

C-clamps, firmly clamp a straight edge to the

workpiece and guide the saw along the straight edge

to achieve a straight rip cut. Do not bind the blade in

the cut. If using the optional rip guide, see the

following instructions and Figure 22.

ALTERNATEMETHODFORRIPCUTTING

STRAIGHT

EDGE

C-CLAMPS

WORKPIECE

Fig. 21

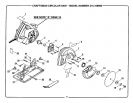

TO ASSEMBLE OPTIONAL RIP GUIDE

• Unplug your saw.

_ WARNING: Failure to unplug your saw could

result in accidental starting causing possible

serious personal injury,

• Place rip guide through holes in saw base as

shown in Figure 22.

15

EDGEGUIDE PLACERIP

GUIDETHRUHOLES

Fig. 22

• Adjust rip guide to the width needed.

• Tighten rip guide screw securely.

When using a rip guide, position the face of the rip

guide firmly against the edge of workpiece. This

makes for a true cut without pinching the blade. The

guiding edge of workpiece must be straight for your

cut to be straight. Use caution to prevent the blade

from binding in the cut.