Owner's Manual Model No. 875.199340 Owner's Manual Model No. 875.199340

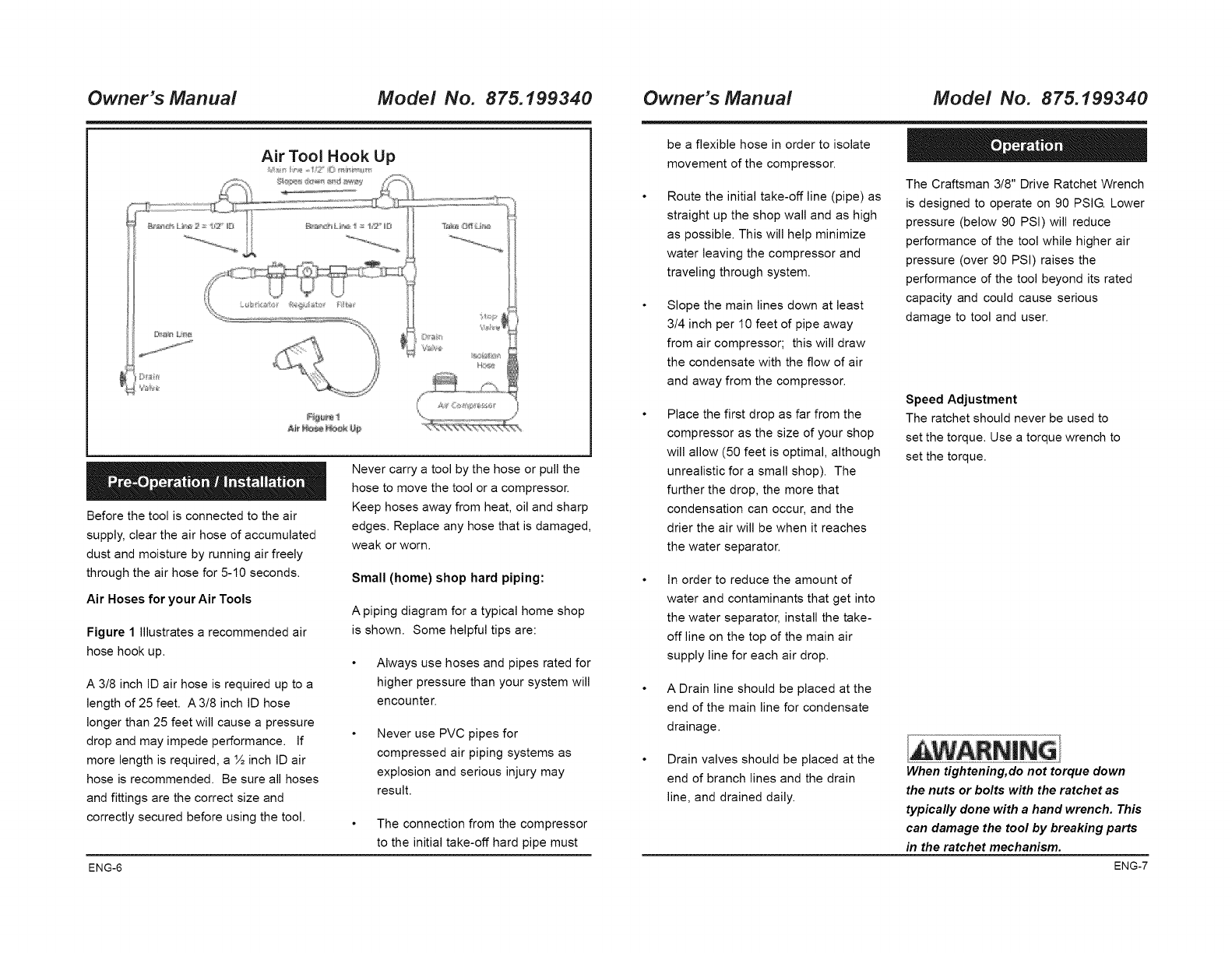

Air Tool Hook Up

Before the tool is connected to the air

supply, clear the air hose of accumulated

dust and moisture by running air freely

through the air hose for 5-10 seconds.

Air Hoses for your Air Tools

Figure 1 Illustrates a recommended air

hose hook up.

A 3/8 inch ID air hose is required up to a

length of 25 feet. A 3/8 inch ID hose

longer than 25 feet will cause a pressure

drop and may impede performance. If

more length is required, a ½ inch ID air

hose is recommended. Be sure all hoses

and fittings are the correct size and

correctly secured before using the tool.

Never carry a tool by the hose or pull the

hose to move the tool or a compressor.

Keep hoses away from heat, oil and sharp

edges. Replace any hose that is damaged,

weak or worn.

Small (home) shop hard piping:

A piping diagram for a typical home shop

is shown. Some helpful tips are:

Always use hoses and pipes rated for

higher pressure than your system will

encounter.

Never use PVC pipes for

compressed air piping systems as

explosion and serious injury may

result.

The connection from the compressor

to the initial take-off hard pipe must

ENG-6

be a flexible hose in order to isolate

movement of the compressor.

Route the initial take-off line (pipe) as

straight up the shop wall and as high

as possible. This will help minimize

water leaving the compressor and

traveling through system.

Slope the main lines down at least

3/4 inch per 10 feet of pipe away

from air compressor; this will draw

the condensate with the flow of air

and away from the compressor.

Place the first drop as far from the

compressor as the size of your shop

will allow (50 feet is optimal, although

unrealistic for a small shop). The

further the drop, the more that

condensation can occur, and the

drier the air will be when it reaches

the water separator.

In order to reduce the amount of

water and contaminants that get into

the water separator, install the take-

off line on the top of the main air

supply line for each air drop.

A Drain line should be placed at the

end of the main line for condensate

drainage.

Drain valves should be placed at the

end of branch lines and the drain

line, and drained daily.

The Craftsman 3/8" Drive Ratchet Wrench

is designed to operate on 90 PSIG. Lower

pressure (below 90 PSI) will reduce

performance of the tool while higher air

pressure (over 90 PSI) raises the

performance of the tool beyond its rated

capacity and could cause serious

damage to tool and user.

Speed Adjustment

The ratchet should never be used to

set the torque. Use a torque wrench to

set the torque.

When tightening, do not torque down

the nuts or bolts with the ratchet as

typically done with a hand wrench. This

can damage the tool by breaking parts

in the ratchet mechanism.

ENG-7