10- ENG

D24445

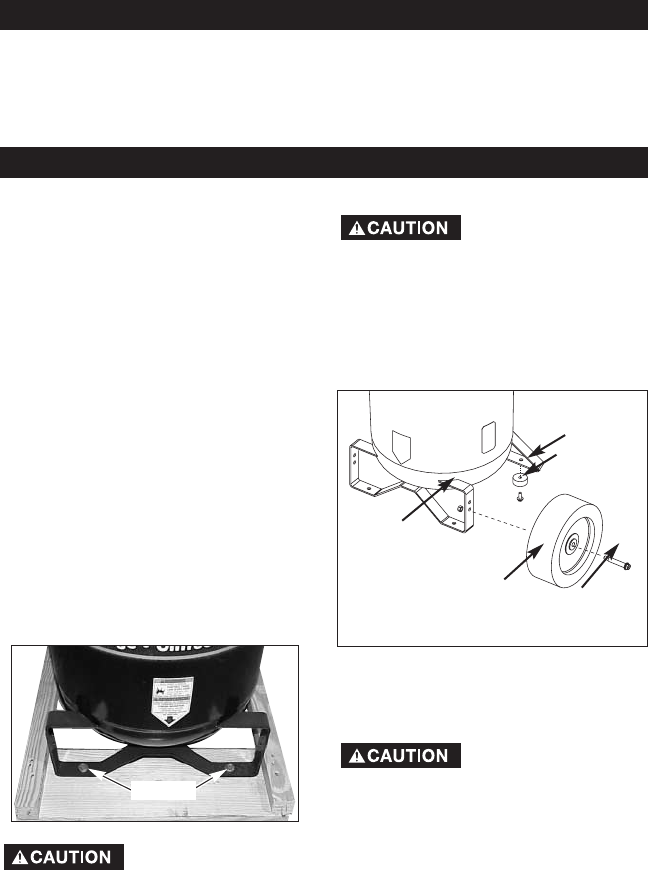

Assemble Wheels

It will be necessary

to brace or support

one side of the outfit when

installing the wheels because the

compressor will have a tendency to

tip.

1. Attach wheels with shoulder

bolts and nuts as shown.

2. Tighten securely. NOTE: The

outfit will sit level if the wheels

are properly installed.

The wheels and

handle do not

provide adequate clearance,

stability or support for pulling the

unit up and down stairs or steps.

The unit must be lifted, or pushed

up a ramp.

Assemble Rubber Feet

1. Attach rubber feet with the

screws provided as shown in

previous figure.

2. Tighten securely.

Rubber

Feet

Screw

Nut

Wheel

Shoulder

Bolt

ASSEMBLY

Tools Required for Assembly

1 - 9/16” socket or open end wrench

1 - 1/2” socket or open end wrench

Unpacking

1. Remove all packaging leaving

the air compressor on the pallet.

2. Remove and discard the (4)

screws holding the air

compressor to the pallet.

It may be

necessary to brace

or support one side of the air

compressor when removing the

pallet because the air compressor

will have a tendency to tip.

3. Carefully remove the air

compressor from the pallet.

Screws

Contents of Carton

1 - Air Compressor

2 - Wheels

2 - Shoulder Bolts, 3/8-16

2 - Hex Nuts, 3/8-16

2 - Rubber Bumpers

2 - Screws, 1/4-20 x .75

DUTY CYCLE

Air compressors should be operated

on not more than a 50% duty cycle.

This means an air compressor that

pumps air more than 50% of one

hour is considered misuse, because

the air compressor is undersized for

the required air demand. Maximum

compressor pumping time per hour is

30 minutes.