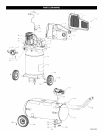

Pressure Switch (see A)

This switch turns on the compressor. It is operated manually,

but when in the ON position, it allows the compressor to start up

or shut down automatically, without warning, upon air demand.

ALWAYS set this switch to OFF when the compressor is not

being used, and before unplugging the compressor.

Pressure Relief Valve (see B)

If the pressure switch does not shut down the motor when

pressure reaches the preset level, this valve wilt pop open

automatically to prevent over pressurization. To operate

manually, pull the ring on the valve to relieve air pressure in the

tank.

Tank Pressure Gauge (see C)

This gauge measures the pressure level of the air stored in

the tank. It isnot adjustable by the operator, and does not

indicate line pressure.

Air Pressure Regulator (see D)

This air pressure regulator enables you to adjust line

pressure to the tool you are using.

__ Never exceed the maximum working

pressure of the tool.

Turn the knob clockwise to increase pressure, and

counterclockwise to decrease pressure.

Regulated Pressure Gauge (see E)

This gauge measures the regulated line pressure.

Quick Connect (see F)

A quick release for attaching and removing the air hose.

B

Horizontal tank

A

B

Vertical tank

Fig. 3

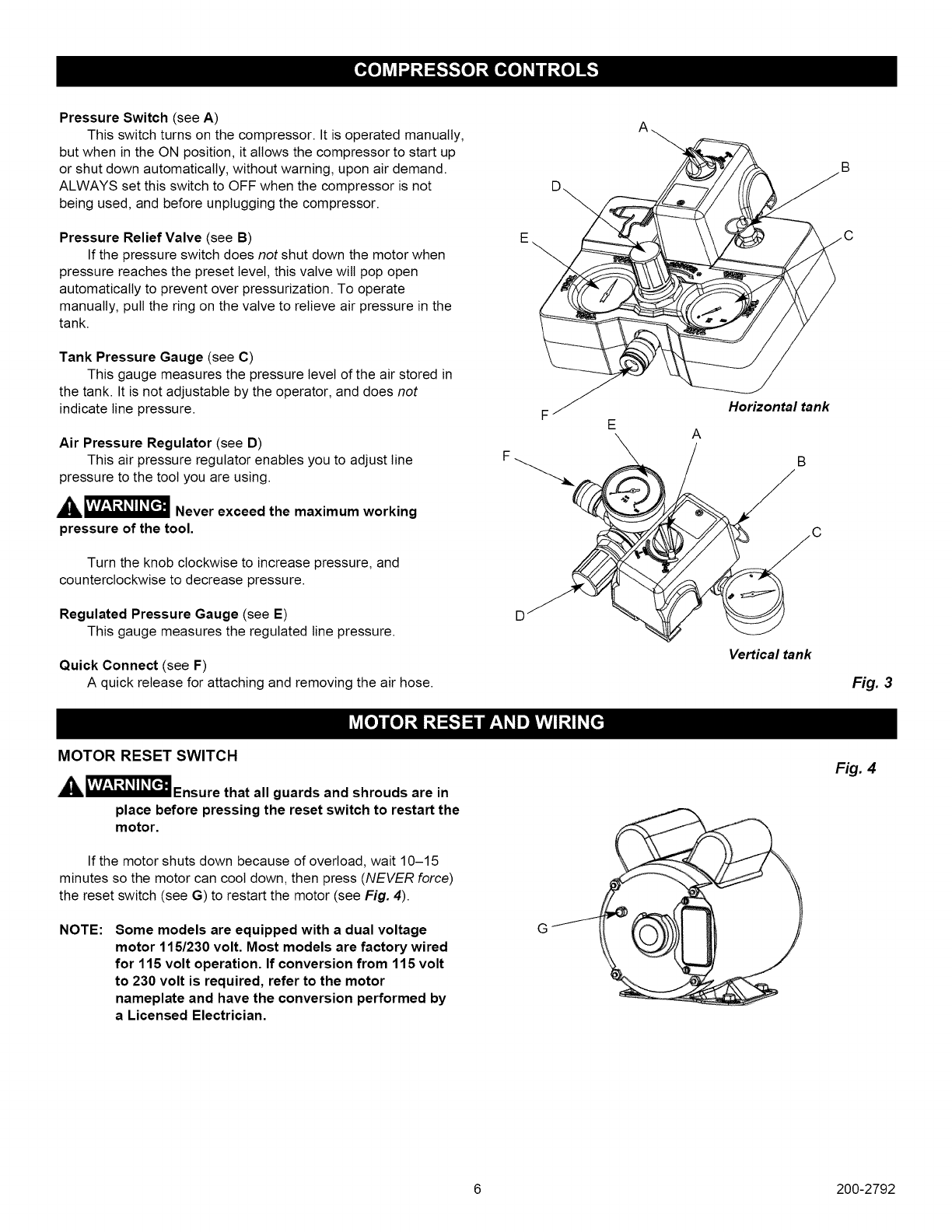

MOTOR RESET SWITCH

__Ensure that all guards and shrouds are in

place before pressing the reset switch to restart the

motor.

If the motor shuts down because of overload, wait 10-15

minutes so the motor can cool down, then press (NEVER force)

the reset switch (see G) to restart the motor (see Fig. 4)

NOTE:

Some models are equipped with a dual voltage

motor 115/230 volt. Most models are factory wired

for 115 volt operation. If conversion from 115 volt

to 230 volt is required, refer to the motor

nameplate and have the conversion performed by

a Licensed Electrician.

G

Fig. 4

6 200-2792