REMOVING BITS

See Figure 7.

• Lockswitch trigger on your drill by placing the

direction of rotation selector incenter position.

See Figure 2.

• Loosen the chuckjaws from drillbit.

• To loosen: grasp and hold the collar of the chuck

with one hand, while rotating chuck body with your

other hand. Note: Rotate chuck body in the

direction of the arrow marked UNLOCK to loosen

chuck jaws.

• Do not use a wrench to tighten or loosen the

chuck jaws.

• Remove drillbit from chuck jaws.

ADJUSTABLE TORQUE CLUTCH

See Figure9.

Your drill is equipped with an adjustable torque clutch

for driving different types of screws into different

materials. The proper setting depends on the type of

material and the size of screw you are using.

TO ADJUST TORQUE

• Identify the twenty four torque indicator settings

located on the front of your drill. See Figure 9.

• Rotate adjusting ring to the desired setting.

• 1 - 4 For driving small screws.

• 5 - 8 For driving screws into soft

material.

• 9 - 12 For drivingscrews into soft and hard

materials.

• 13 - 16 For driving screws in hard wood.

• 17 - 20 For driving large screws.

• 21 - ,11 For heavy ddlling.

TO DECREASE

TORQUE ADJUSTING

RING

,_ WARNING: Always wear safety goggles or

safety glasses with side shields when operating

tools. Failure to do so could result in objects

being thrown into your eyes, resulting inpossible

serious injury.

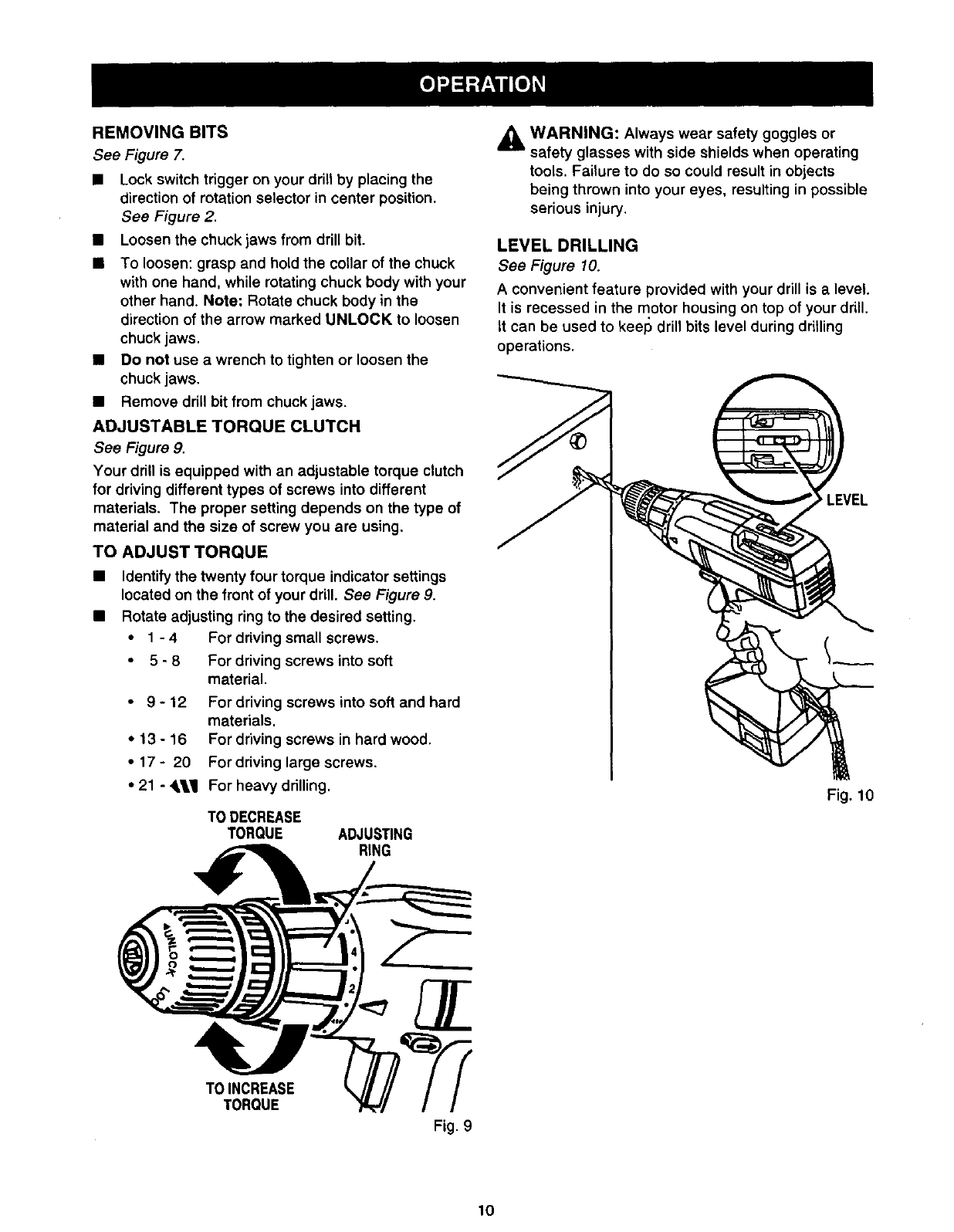

LEVEL DRILLING

See Figure 10.

A convenient feature provided with your drill is a level.

It is recessed in the motor housing ontop of your drill.

It can be used to keep drill bits level during drilling

operations.

LEVEL

Fig. 10

TOINCREASE

TORQUE

Fig. 9

10