10

INSTALLING OR REMOVING

ABRASIVE BELT

Your machine uses a 6"x48" belt. To install or remove the

belt, proceed as follows:

DISCONNECT MACHINE FROM POWER SOURCE.

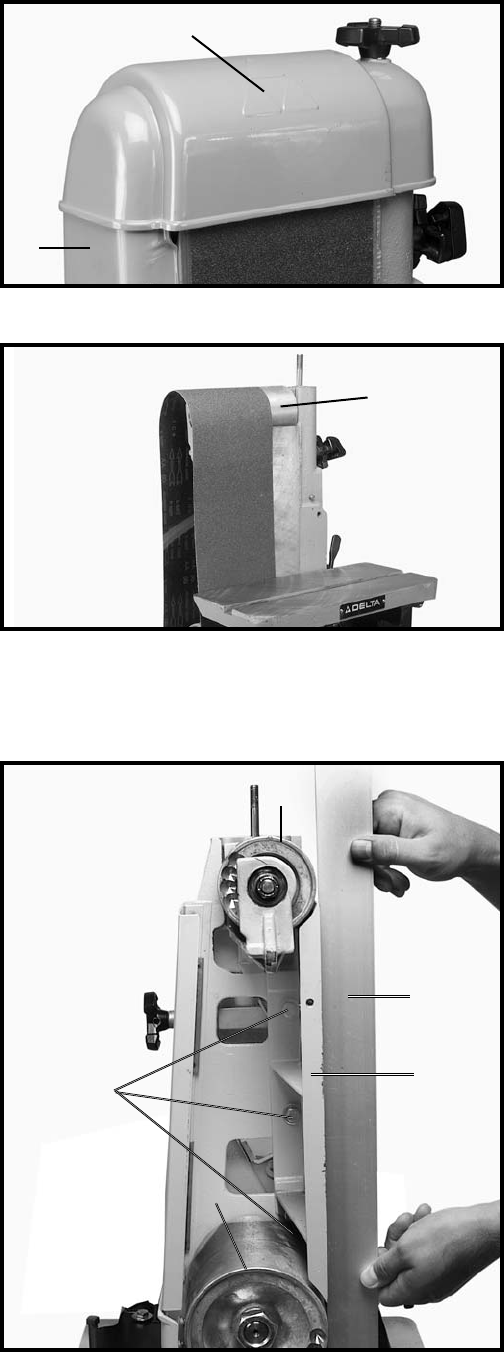

1. Remove the idler drum guard (A) and side guard (B)

Fig. 20.

2. Turn the belt tension handle counterclockwise to

reduce belt tension to a minimum. NOTE: It may be

necessary when reducing belt tension that downward

pressure be applied on the idler pulley (C) Fig. 21.

3. The sanding belt can then be easily slipped off or

onto the drums, as shown in Fig. 21.

IMPORTANT: Lapless sanding belts can be run in either

direction. Lapped belts should be installed so that the

work will run OFF the lapped portion of the belt and not

into the edge of the lap. Most sanding belts have a

directional arrow on the inside of the belt to show the

direction of rotation.

AFTER INSTALLING A NEW BELT, THE BELT MUST

BE ADJUSTED FOR PROPER TENSION AND

TRACKING.

Fig. 20

Fig. 21

ADJUSTING THE PLATEN

The platen (A) Fig. 24, is set at the factory 1/32 of an inch

higher than the crown of the drums (B). This allows the

belt, when properly tensioned, to lay flat on the platen

and eliminate stretching and bulging which might occur

if the platen is not at the right height.

When using the machine with a loose belt for

"strapping," the platen is removed and replaced as

follows:

DISCONNECT MACHINE FROM POWER SOURCE.

1. Remove the side cover (B) Fig. 20 and top idler drum

guard (A) Fig. 20.

2. Remove the three screws (C) Fig. 26, that attach the

platen to the machine and remove the platen.

3. When replacing the platen, attach it to the machine

with the three screws (C) Fig. 26. Do not tighten the three

screws.

4. Using a straight edge (D) adjust the platen (A) Fig. 26,

so it is 1/32" higher than the crown of the drums (B),

and tighten the three screws (C).

Fig. 26

D

A

B

B

C

A

B

C