16

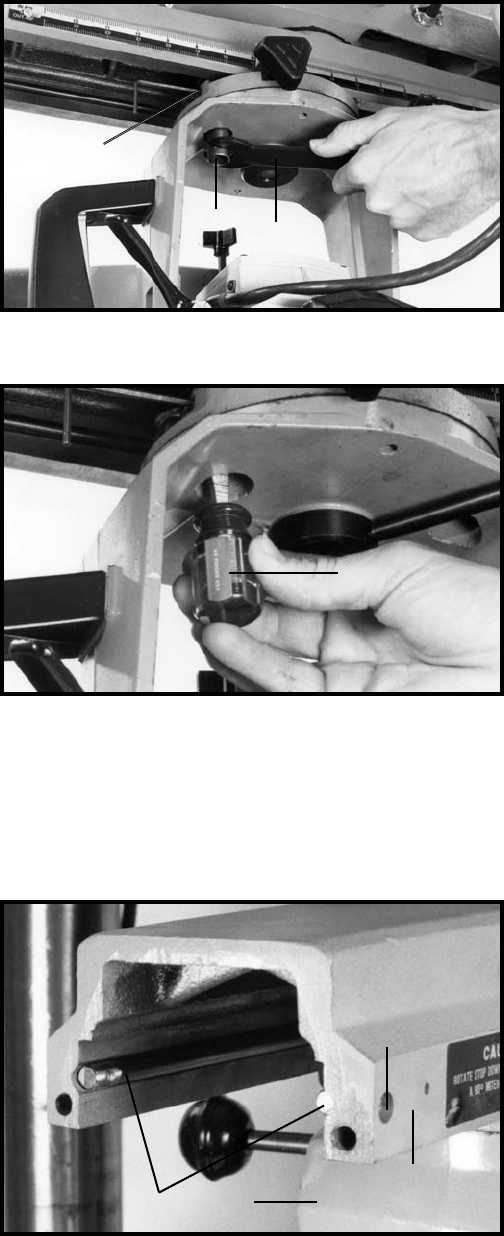

Fig. 39

Fig. 40

Fig. 41

ADJUSTING CUTTINGHEAD

BALL BEARINGS AGAINST

TRACK RODS

The carriage is mounted on four pre-loaded,

prelubricated, shielded ball bearings: two on fixed shafts

(on saw blade side of track arm); the other two on

adjustable eccentric shafts.

The ball bearings must ride smoothly and evenly against

the track rods to do accurate work. If wear should ever

develop in the track rods causing “play” between the ball

bearings and the track rods, the ball bearings can be

adjusted as follows:

1. DISCONNECT TOOL FROM POWER SOURCE.

2. Move the cuttinghead to the center of the track, and

check to see if any play is present.

3. To adjust, place special wrench socket (A) Fig. 39,

supplied with the saw, over hexagon nut, located under-

neath the carriage. Place one of the wrenches (B)

supplied, on flats on special wrench socket (A) and

loosen hexagon nut.

4. Loosen set screw (C) Fig. 39, with allen wrench to

release locking action on eccentric shaft.

5. Using a small screwdriver (D) Fig. 40, turn screw

slightly until all play is removed.

6. Lock set screw (C) Fig. 39, and tighten hex jam nut

with special socket wrench (A).

7. Use the same procedure to adjust rear bearing.

ADJUSTING TRACK RODS

After a period of heavy use the two track rods (A) Fig. 41,

may in time show signs of wear especially where the

cuttinghead is used most often in the track arm. If this

happens you will have an uneven bearing surface for the

cuttinghead bearings.

If an adjustment should ever become necessary proceed

as follows:

1. DISCONNECT TOOL FROM POWER SOURCE.

2. Remove rear plate from track arm (B) Fig. 41.

3. Remove the cuttinghead assembly (C) Fig. 41, from

the track arm (B).

4. Remove four screws (D) Fig. 41, one of which is

shown, and rotate track rods (A) 180 degrees.

5. Replace track rods (A) Fig. 41, inside track arm (B)

and fasten with four screws (D).

6. Replace the cuttinghead assembly.

7. Replace rear plate on track arm.

C

A

B

D

A

D

B

C