19

ASSEMBLY

SELECTING AND STORING SAW BLADES

Riving knives must be matched to saw blade

dimensions in order to function effectively.

The saw blade furnished with your new saw is a

10-inch (254 mm) combination blade, used for cross

cutting (across the grain) and ripping (with the grain)

through the workpiece. The arbor hole of the blade is

5/8-inch (16 mm) diameter. This blade will produce a

good quality cut for most applications.

There are many types of blades available to do specific

and special jobs such as cross cut only, rip only, dado

cuts thin plywood, paneling, etc.

Use only saw blades designed for maximum safe

operating speeds of 3,600 RPM or greater.

Saw blades should always be kept sharp. It is

recommended that you locate a reputable sharpening

service to sharpen your blades when needed.

Never stack blades on top of one another to store.

Place material such as cardboard between them to

keep the blades from coming in contact with one

another, or place them in storage drawer.

Abrasive wheels or blades (including diamond) should

not be used on this saw.

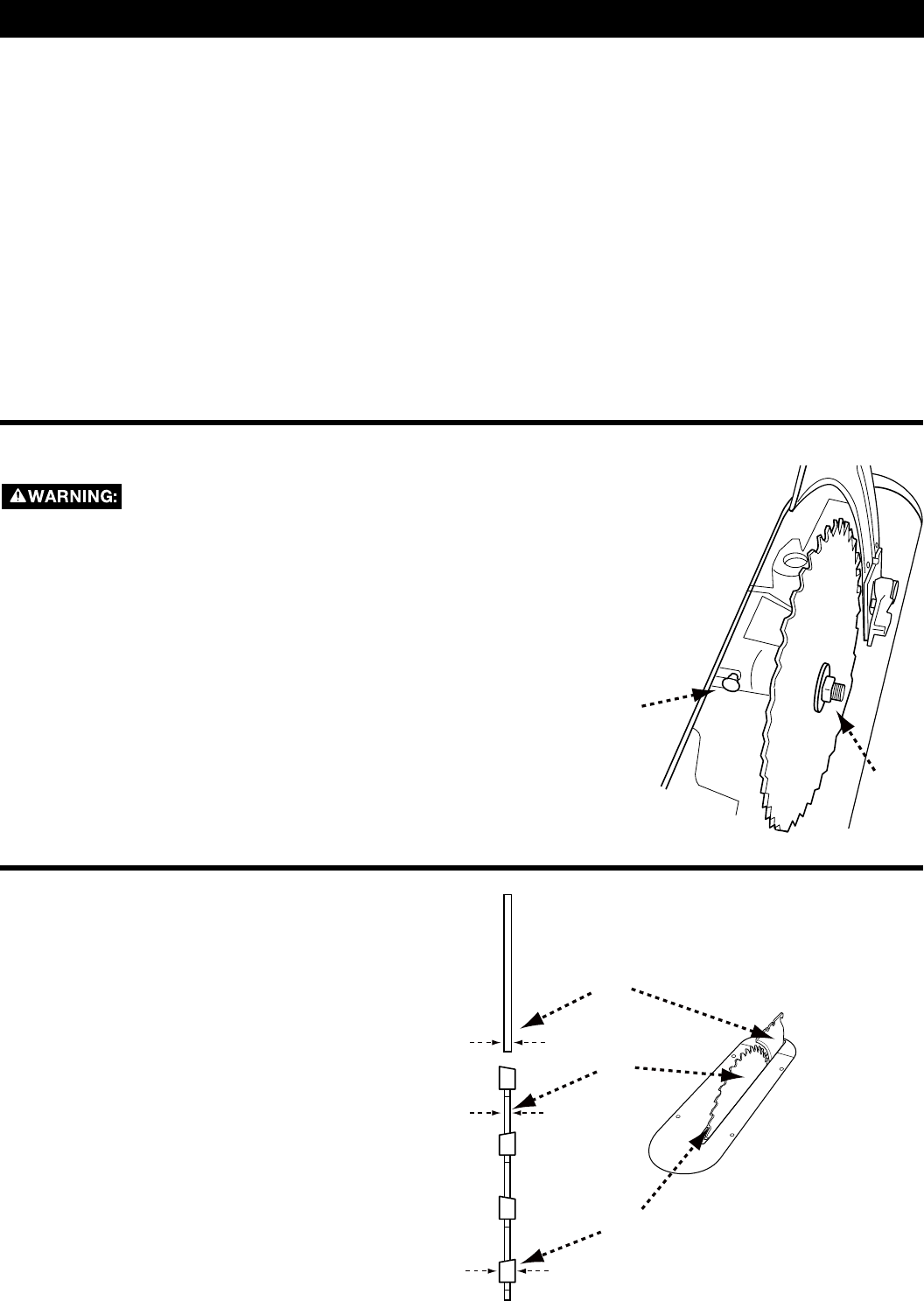

RIVING KNIFE POSITION

NOTE: Safety devices, blade guard assembly and anti-

kickback assembly have been removed in Figure 18 in

order to show the location of specific features. When

operating the saw, these safety devices should be in

place and working properly.

The riving knife is a flat plate that fits into the cut made

by the saw blade and effectively fights kickback by

lessening the tendency of the blade to bind in the cut.

It must be installed and properly positioned for every

through cut and for every non-through cut unless the

riving knife would interfere with the workpiece.

The riving knife thickness (A) must be greater than the

blade body or plate thickness (B) and less than the

kerf or cutting width (C) as shown in Figure 15. The

riving knife provided with this saw is 2.2mm thick and

may be used only with a 10-inch (254mm) blade with

0.102-inch (2.6mm) minimum kerf width and 0.073-inch

(1.8mm) maximum body thickness. Do not attempt to

CHANGING THE SAW BLADE

• Use only 10-inch (254 mm) diameter blades with

5/8-inch (16mm) arbor holes, rated at 3,600 rpm or

higher, 0.102-inch (2.6mm) minimum kerf width and

0.073-inch (1.8mm) maximum body thickness.

• To reduce the risk of injury, turn unit off and

disconnect it from power source before installing

and removing blades and accessories, before

adjusting and when making repairs. An accidental

start-up can cause injury.

1. Remove the throat plate and raise the saw blade

to its maximum height.

2. Push and hold arbor lock button (A) shown in

Figure 17.

3. Use included arbor wrench to remove the blade

retaining nut and flange (B). Remove old blade.

B

A

FIGURE 17

use this riving knife with blades that are not

within these dimensions.

4. Place the new blade on the arbor

with the teeth pointing down as

the blade rotates toward the

front of the saw table.

5. Replace and tighten the blade

retaining nut and flange.

6. Replace throat plate.

FIGURE 18

A

B

C

PREPARING TO CUT

(continued)