12

HOW TO TURN SPINDLES

Spindle turning is the principal type of wood turning (chair and table legs, lamp stems, etc.) The turning of spindles can be done with

either a scraping or cutting technique. The cutting technique, by virtue of faster wood removal and a cleaner surface, is the preferred

method.

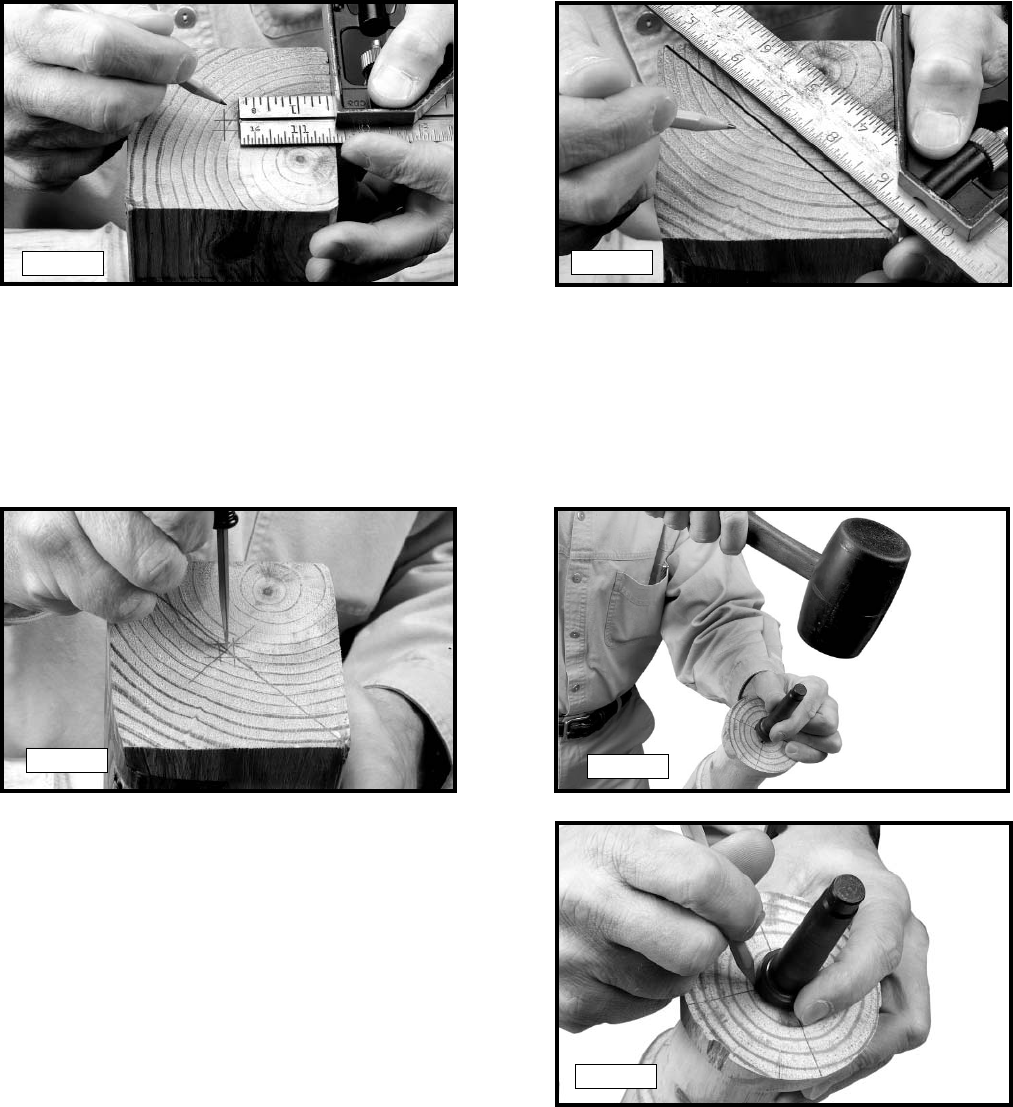

Fig. 27

CENTERING THE WORK

Wood stock for any spindle turning should be approximately square, and the ends should be square with the sides. Two common

methods of determining the center are shown in Figs. 27 and 28. In Fig. 27, a distance a little more or a little less than one-half the

width of the stock is set off from each of the four sides. The small square set off in the center can then be used in marking the true

center. The diagonal method, Fig. 28, consists of drawing lines from corner to corner, with the intersection marking the center of the

work.

Fig. 28

After marking each end, mark the true center with a punch awl (Fig. 29). If the stock is hardwood, the centers should be drilled to a

depth of about 1/8”. The spur or live center is then placed against one end of the work and seated by striking with a mallet (Fig. 30).

In hardwood, make a starting seat for the spur center by sawing on the diagonal lines, and drilling a small hole at the intersection.

After driving the center, hold the center and the work together and fit both immediately to headstock spindle. If you are not using a

ball bearing center, the end of work at tailstock center should be oiled. Place the lubricant on the wood either before or after it is put

on the lathe. Many turners use beeswax, tallow, or a wax-and-oil mixture as a lubricant. A ball bearing center is ideal because it

eliminates lubricating. If the work is to be removed from the lathe before completion, an index mark should be made as a guide for

re-centering (Fig. 31). A permanent indexer can be made by grinding off one corner of one of the spurs.

Fig. 29

Fig. 30

MOUNTING THE WORK

Mount the work by moving the tailstock to a position about 1”

or 1-1/2” from the end of the workpiece, and locking it in this

position. Advance the tailstock center by turning the feed

handle until the center cup makes contact with the work. Do

not support the work on the center pin alone. Always have the

rim of the center cup imbedded at least 1/8” into the work.

Continue to advance the center while slowly rotating the work

by hand. After it becomes difficult to turn the work, slack off

on the feed about one-quarter turn and lock the tailstock

spindle.

Fig. 31