11

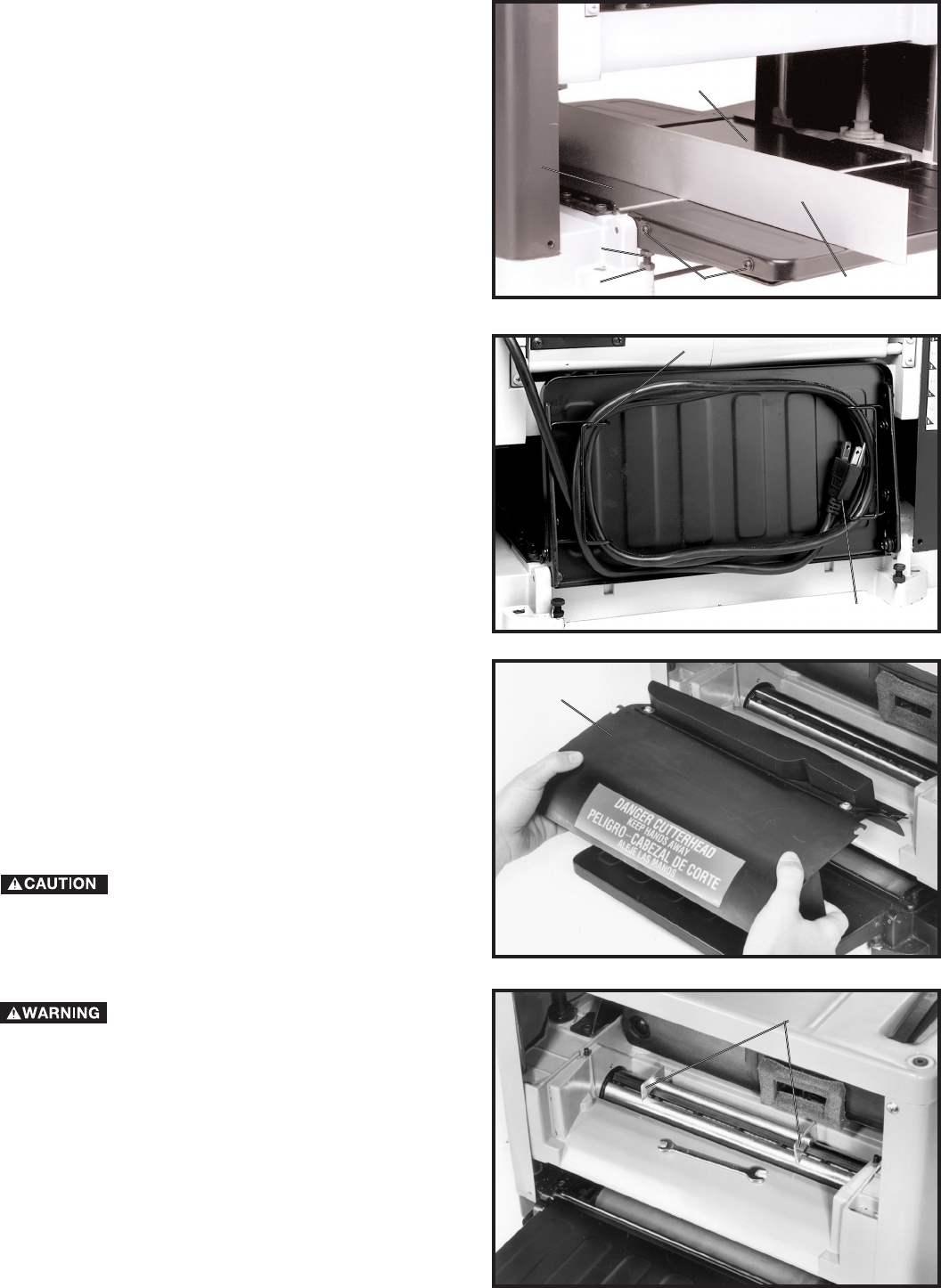

Fig. 17

Fig. 18

Fig. 19

Fig. 20

LEVELING

EXTENSION TABLES

For optimum performance, the extension tables, one of

which is shown at (A) Fig. 17, must be level with the

planer table. To check the extension tables and adjust if

necessary, proceed as follows:

1. Place a straight edge (B) Fig. 17, on the planer table

(A) with one end extending out over the extension table

as shown. Check to see if the infeed table is level with

the planer table on both ends of the planer table.

2. If an adjustment is necessary, loosen locknut (C)

Fig. 17, and adjust stop screw (D) on each side of the

extension table (A) until the extension table is level with

the planer table (E); then tighten locknut (C). Recheck

and make certain inside edge of table extension is level

with the planer table. If necessary, loosen two screws

(F), adjust extension table and retighten two screws (F).

Adjust opposite side of the table in the same manner.

Make certain the extension table is solidly supported

when there is downward pressure on the table.

3. Check and adjust outfeed extension table in the

same manner.

STORING THE POWER CORD

Wire hangers (A) Fig. 18, are provided on the underside

of the infeed extension table as shown, to store the

power cord (B) when the planer is not in use and when

transporting the machine.

ADJUSTING KNIVES

IF THE KNIVES ARE TO BE REMOVED

FOR SHARPENING OR REPLACEMENT, EXTREME

CARE SHOULD BE TAKEN AS THE KNIVES ARE

VERY SHARP.

To check and adjust the knives, proceed as follows:

DISCONNECT MACHINE FROM POWER

SOURCE.

1. Lower the head assembly by turning handle (B) Fig.

15.

2. Remove chip deflector (A) Fig. 19.

3. Carefully place knife setting gage (B) Fig. 20, on the

cutterhead so the rounded sections are directly over the

knife as shown. When adjusted correctly, the knife

should just contact the bottom of the center portion at

each end of gage (B). Check the other knife in the same

manner.

A

B

E

C

D

F

B

A

B

A