9

English

can be made with the same twist drills used for metal. These bits

may overheat unless pulled out frequently to clear chips from the

flutes. For larger holes, use spade bits, power auger bits, or hole

saws. Work that is apt to splinter should be backed up with a block

of wood.

HAMMERDRILL OPERATION

1. When drilling, use just enough force on the hammer to keep

it from bouncing excessively or “rising” off the bit. Too much

force will cause slower drilling speeds, overheating, and a lower

drilling rate.

2. Drill straight, keeping the bit at a right angle to the work. Do not

exert side pressure on the bit when drilling as this will cause

clogging of the bit flutes and a slower drilling speed.

3. When drilling deep holes, if the hammer speed starts to drop

off, pull the bit partially out of the hole with the tool still running

to help clear debris from the hole.

4. For masonry, use carbide-tipped bits or masonry bits. A smooth

even flow of dust indicates the proper drilling rate.

Chipping and Chiselling

1. To switch from hammer drilling to chiselling, first insert the SDS-

plus® chisel and check if it is properly locked.

2. When switching from hammer drilling mode to chiselling mode,

turn the chisel to the desired position. If you find resistance

during mode change, turn the chisel slightly to engage the

spindle lock.

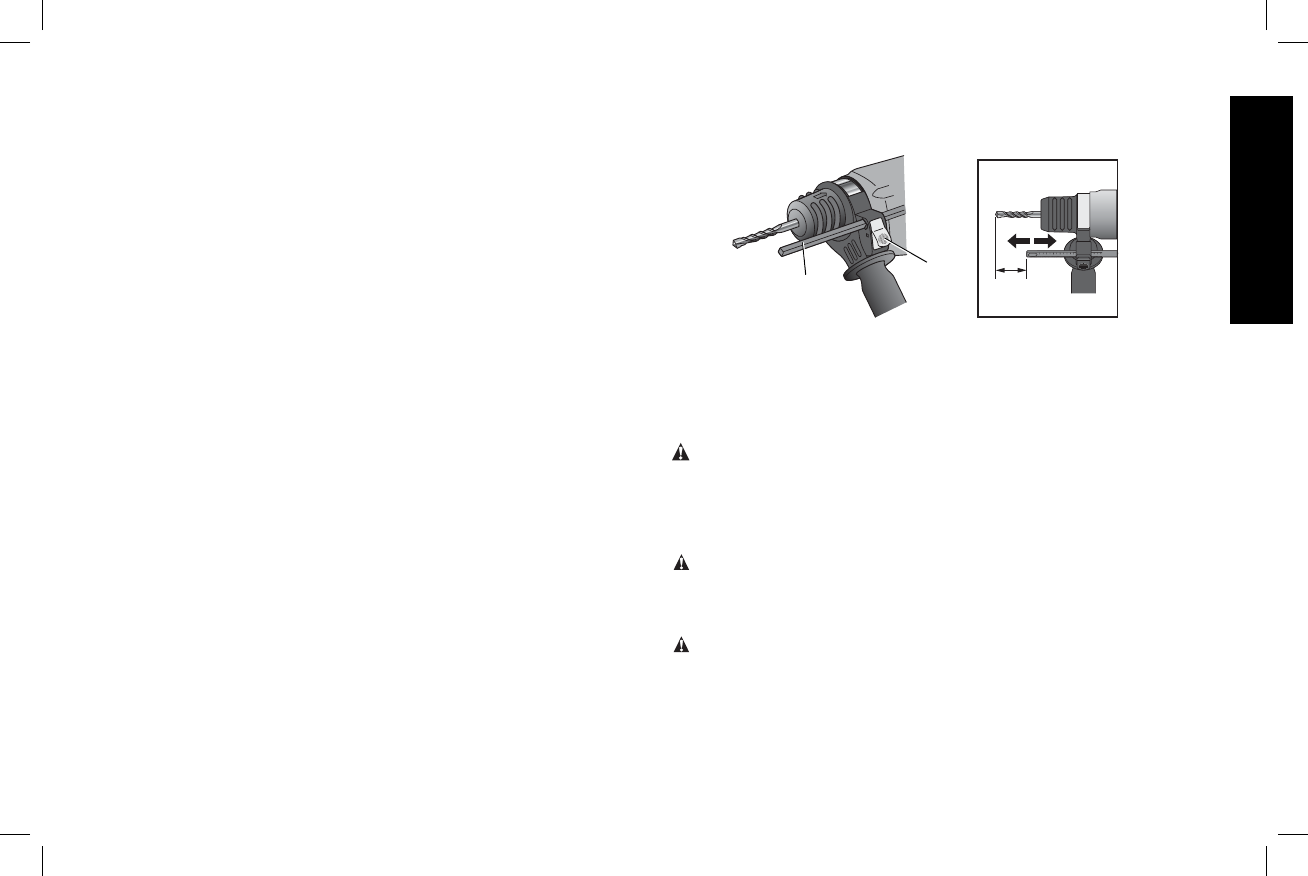

Depth Rod (Fig. 4)

TO ADJUST THE DEPTH ROD

1. Push in and hold the depth rod release button (J) on the side

handle.

2. Move the depth rod (D) so the distance between the end of the

rod and the end of the bit equals the desired drilling depth.

3. Release the button to lock rod into position. When drilling

with the depth rod, stop when end of rod reaches surface of

material.

FIG. 4

J

D

MAINTENANCE

Your DEWALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and removing

accessories, before making any adjustments or removing/installing

attachments or accessories.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at

least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye

protection and proper NIOSH/OSHA/MSHA respiratory protection

when performing this.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.