6

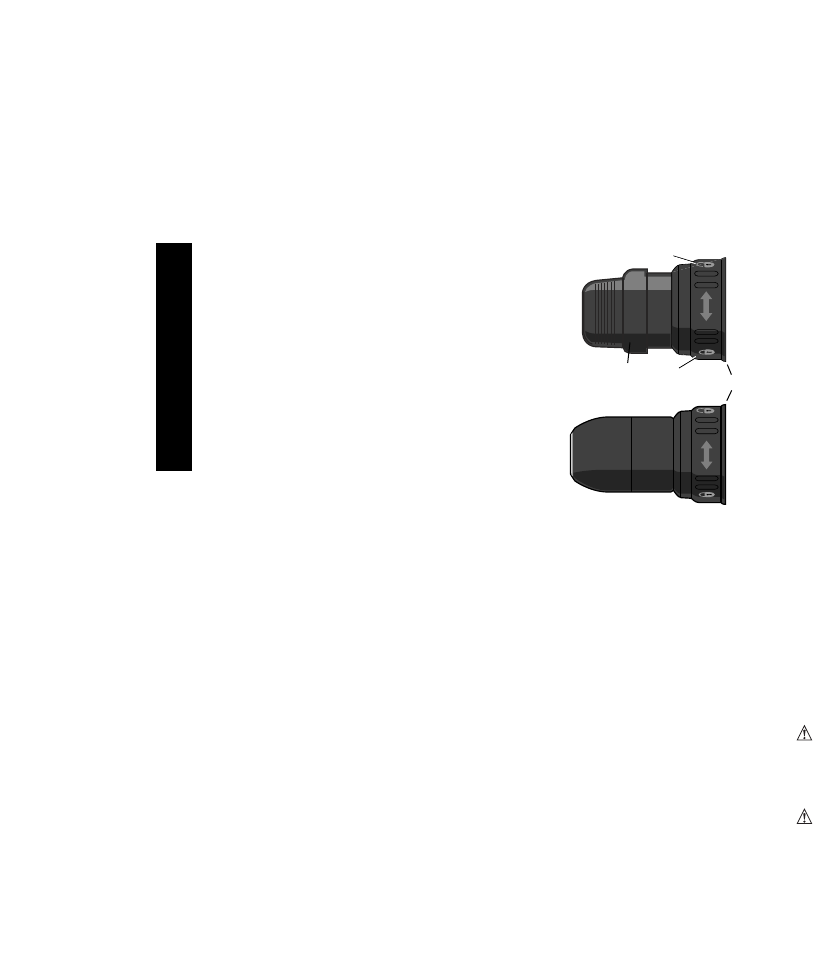

does not function when the 3 jaw keyless

chuck is used.

Both the SDS and 3 jaw keyless chuck can

be easily removed by turning the collar (E)

into the unlocked position (F) to release the

chuck (Fig. 4).

The SDS and 3 jaw keyless chuck can be

easily attached by inserting the chuck into

the spindle of the tool and turning the collar

to the locked position (G). The chuck will

click when properly installed.

DRILLING IN METAL

(D25103, D25203, D25303, D25304)

An SDS to round shank adaptor chuck is required. Ensure that tool is

in drill-only mode. (D25101, D25201 has no drill-only mode). Start

drilling with slow speed and increase to full power while applying firm

pressure on the tool. A smooth even flow of metal chips indicates the

proper drilling rate. Use a cutting lubricant when drilling metals. The

exceptions are cast iron and brass which should be drilled dry. The

cutting lubricants that work best are sulphurized cutting oil or lard oil;

bacon-grease will also serve the purpose.

NOTE: Large (5/16" to 1/2") holes in steel can be made easier if a pilot

hole (5/32" to 3/16") is drilled first.

DRILLING IN WOOD

(D25103, D25203, D25303, D25304)

An SDS to round shank adaptor chuck is required. Ensure that tool is

in drill-only mode. (D25101, D25201 have no drill-only mode). Start

drilling with slow speed and increase to full power while applying firm

pressure on the tool. Holes in wood can be made with the same twist

drills used for metal. These bits may overheat unless pulled out fre-

quently to clear chips from the flutes. For larger holes, use spade bits,

power auger bits, or hole saws. Work that is apt to splinter should be

backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use SDS carbide tipped bits rated for per-

cussion drilling and be certain that the bit is sharp. Use a constant and

firm force on the tool to drill most effectively. A smooth, even flow of

dust indicates the proper drilling rate.

Depth Rod

TO ADJUST THE DEPTH ROD

1. Push in and hold the button on the side handle.

2. Move the rod so the distance between the end of the rod and the

end of the bit equals the desired drilling depth.

3. Release the button to lock rod into position.

When drilling with the depth rod, stop when end of rod reaches

surface of material.

Maintenance

CLEANING & LUBRICATION

Use only mild soap and damp cloth to clean the tool. Never let any liq-

uid get inside the tool; never immerse any part of the tool into a liquid.

Self-lubricating bearings are used in the tool and periodic relubrication

is not required. In the unlikely event that service is ever needed, take

your tool to an authorized service location.

Accessories

CAUTION: When handling accessories after use, wear work

gloves. Accessories may be hot and may burn skin.

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

English

FIGURE 4

D

G

F

E