..................Class II Construction …/min ............revolutions or reciprocation

......................(double insulated) .....................per minute

BPM ................ beats per minute

SAVE THESE INSTRUCTIONS

Motor

Your DEWALT tool is powered by a DEWALT built motor. Be sure your power supply agrees

with the nameplate marking. Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWALT tools are factory tested; if this tool does no operate, check the power

supply.

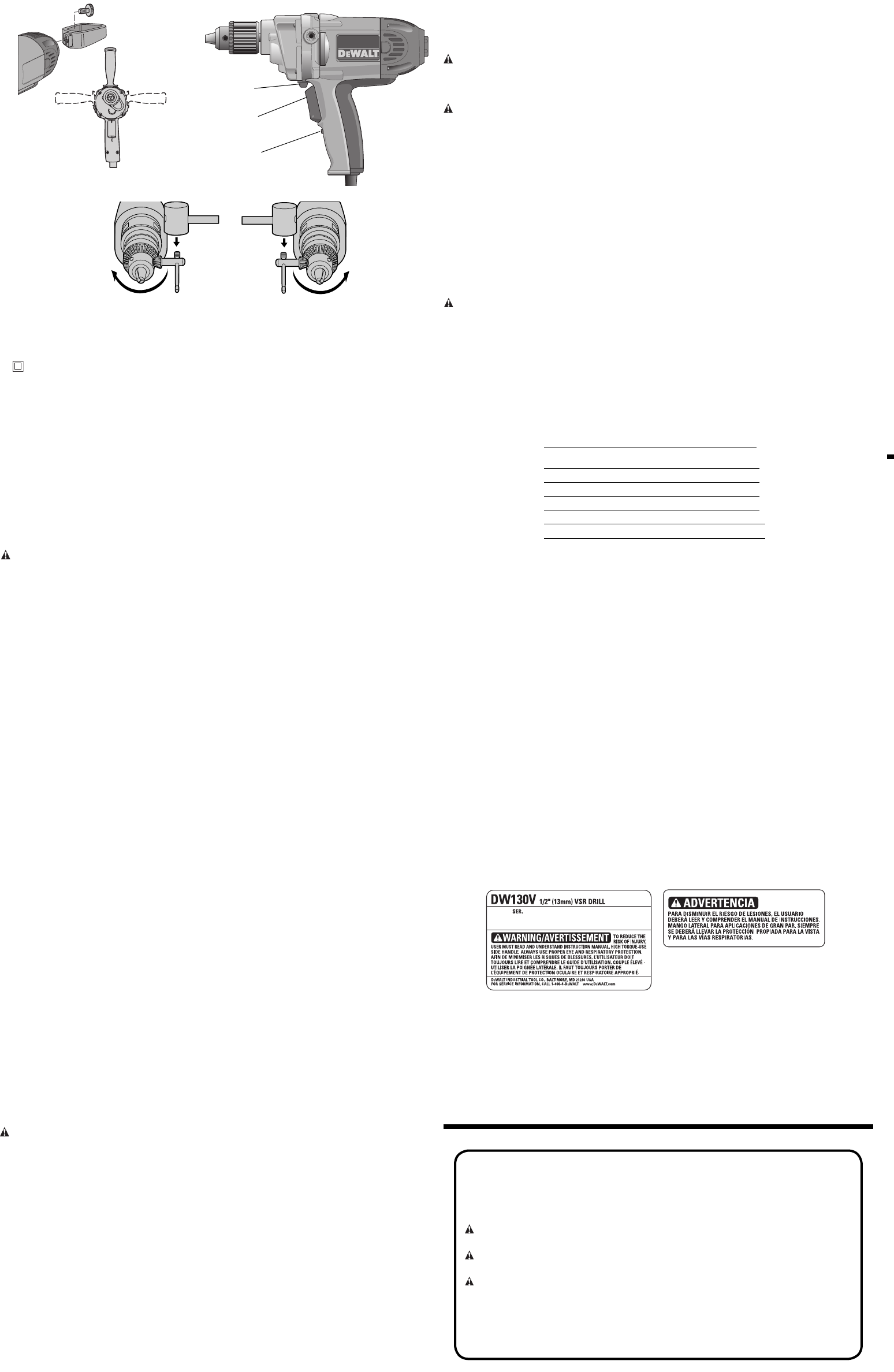

Spade Handle Assembly (Fig. 1)

This spade handle can be attached either horizontally or vertically. Place the handle into the

locating boss on the back of the drill and assemble with holding knob.

Side Handle (Fig. 1)

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed. Failure to do so may result in the side handle slipping during tool

operation and subsequent loss of control. Hold tool with both hands to maximize control.

The side handle can be placed in either side of the drill or the top of the drill according to operator

preference and available working clearance. The spade handle can be temporarily removed if

working clearance at rear of tool is limited. Always replace spade handle when possible.

Switch (Fig. 2)

To start the drill, depress the trigger switch; to stop the drill, release the trigger.

A variable speed trigger switch (A) permits speed control—the farther the trigger is depressed,

the higher the speed of the drill.

NOTE: Use lower speeds for starting holes without a center punch, drilling in metal or plastics,

driving screws or drilling ceramics. Higher speeds are better for drilling wood and composition

boards and using abrasive and polishing accessories.

The reversing lever (B) is used for withdrawing bits from tight holes and removing screws. It is

located above the trigger switch. To reverse the motor, release the trigger switch FIRST and

then push the lever to the right. After any reversing operations, return lever to forward position.

The locking feature (C) is for use when the drill is mounted in a drill stand or otherwise firmly

held…NOT BY HAND.

Do not lock the switch “ON” when drilling by hand so that you can instantly release the trigger

switch if the bit binds in the hole.

Be sure to release the switch locking button before disconnecting the plug from the power sup-

ply. Failure to do so will cause the tool to start immediately the next time it is plugged in. Damage

or injury could result.

Chuck

To insert bit, open chuck jaws by turning collar with fingers and insert shank of bit about 3/4”

(19mm) into chuck. Tighten chuck collar by hand. Place chuck key in each of the three holes and

tighten in clockwise direction. It’s important to tighten chuck with all three holes.

To release bit, turn chuck key counterclockwise in just one hole, then loosen the chuck

by hand.

Chuck Removal (Fig. 3, 4)

1. Place chuck key in chuck as shown in Figure 3. Using a wooden mallet or similar object,

strike key sharply in a CLOCKWISE direction. This will loosen screw inside chuck.

2. Open chuck jaws fully. Insert screwdriver into front of chuck between jaws to engage screw

head. Remove screw by turning clockwise (left-hand thread).

3. Place key in chuck as shown in Figure 4. Using a wooden mallet or similar object, strike

key sharply in a COUNTERCLOCKWISE direction. This will loosen chuck so that it can be

unscrewed by hand.

Drilling

1. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits, power auger bits, or hole

saws. For METAL, use high-speed steel twist drill bits or hole saws. For MASONRY, such

as brick, cement, cinder block etc., use carbide-tipped bits.

2. Be sure the material to be drilled is anchored or clamped firmly. If drilling thin material, use

a wood “back-up” block to prevent damage to the material.

3. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

4. Hold drill firmly to control the twisting action of the drill. Use side handle.

CAUTION: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip

the drill firmly to control the twisting action and avoid injury.

5. IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE

TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO

NOT CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED DRILL

— THIS CAN DAMAGE THE DRILL.

6. To minimize stalling on breaking through the material, reduce pressure on drill and ease the

bit through the last fractional part of the hole.

7. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

DRILLING IN WOOD

Holes in wood can be made with the same twist drills used for metal. These bits may overheat

unless pulled out frequently to clear chips from the flutes. For larger holes, use spade bits,

power auger bits, or hole saws. Work that is likely to splinter should be backed up with a block

of wood.

DRILLING IN METALS

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should

be drilled dry. The cutting lubricants that work best are sulphurised cutting oil or lard oil; bacon

grease will also serve the purpose.

FIG. 3

FIG. 4

FIG. 1

B

A

C

FIG. 2

DRILLING IN MASONRY

Use carbide tipped masonry bits at low speeds. Keep even force on the drill but not so much that

you crack the brittle materials. A smooth, even flow of dust indicates the proper drilling rate.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attach-

ments or accessories.

Cleaning

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

All bearings used are factory lubricated to last the life of the tool. All needle bearings used

receive their lubrication from the grease in the gear case. Clean and relubricate gear case yearly

or whenever servicing requires the gear case to be removed. Use type and quantity of grease

shown on Parts Bulletin packed with your tool.

Gear case is removed by removing the four screws from the front of the tool. If the chuck is too

large to permit removal of the two top screws, see instructions for chuck removal.

Motor Brushes

This DEWALT tool uses an advanced brush system which auto matically stops the tool when the

brushes wear out. This prevents seri ous damage to the motor.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only D

EWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-

D

EWALT (1-800-433-9258) or visit our website www.dewalt.com..

For safety in use, the following accessories should be used only in sizes up to the maximums

shown in the table below.

MAXIMUM RECOMMENDED CAPACITIES

Drill Capacity 1/2" 13mm

RPM 0-550

Steel twist bit 1/2" 13 mm

Auger 1-1/2" 38 mm

Self-feed 3" 76 mm

Spade 1-1/2" 38 mm

Wood holesaw 5" 127 mm

Steel holesaw 4" 102 mm

ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO OR HIGHER THAN

NAMEPLATE RPM OF TOOL WITH WHICH IT IS BEING USED.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by authorized service centers or other

qualified service organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

EWALT for a free replacement.

Définitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

MISE EN GARDE : indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou

modérées.

MISE EN GARDE : utilisé sans le symbole d’alerte à la sécurité, indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des

dommages à la propriété.