13

English

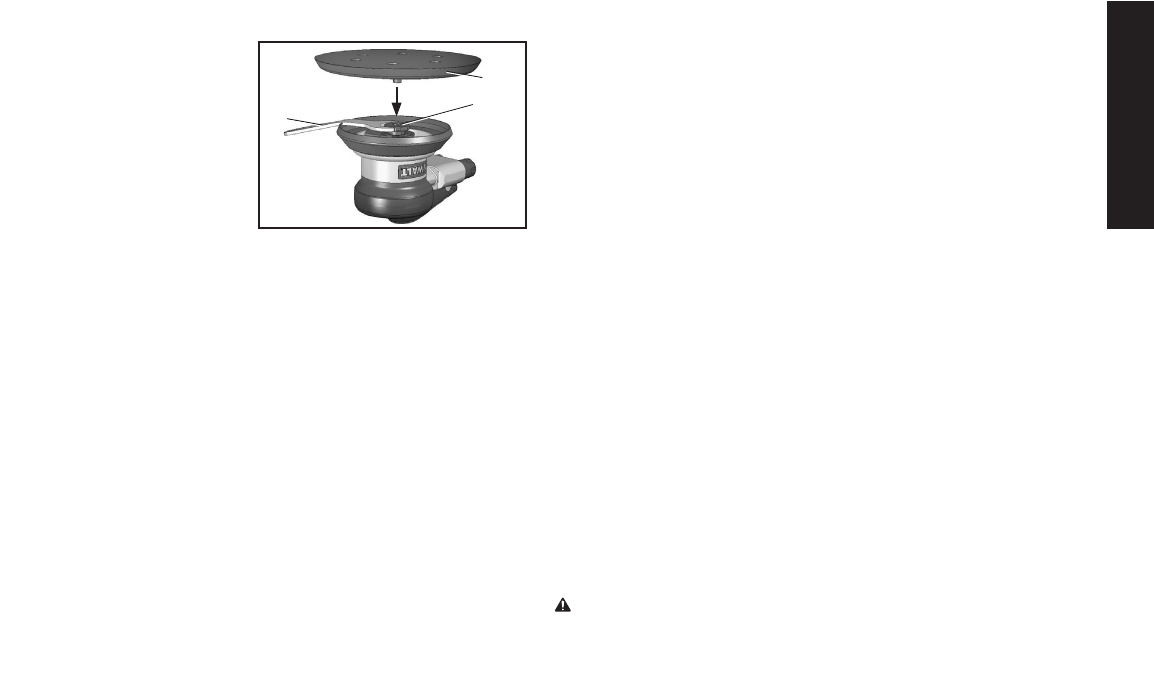

SANDER PAD ASSEMBLY CONTINUED

•Toassemblethesanding

pad (B), place the supplied

wrench onto the balance

shaft nut (H).

•Holdthewrenchfirmlyand

insert the threaded post on

the sander pad (B) into the

balance shaft nut (H).

Tighten by turning the

sander pad (B) clockwise.

OPERATING PROCEDURES

START-UP (FIG. 1, PG. 2)

•Turnontheaircompressorandallowtheairtanktobefilled.

•Settheaircompressorregulatorto90PSI.Thisair

tool operates at a maximum of 90 PSI air pressure.

•Depressthetriggertostartoperatingthetool.

SHUT-DOWN (FIG. 1, PG. 2)

•Releasethetriggertostopthetool.

•Alwaysdisconnectairsupplywhenchangingsandpaperpads.

•Whenjobiscompleted,turnofftheaircompressorandstore

the air tool after lubrication.

Tips

•Beginsandingwithanabrasivegritsandpapercoarse

enough to remove the high spots. Progress to a finer grit

sandpaper until the desired finish is obtained.

•Neverchangefromcoarsegritsandpapertoaveryfinegrit

sandpaper, always progress gradually to the finer grit.

OPERATING INSTRUCTIONS

•Selectasuitableabrasivediscandmakesurethatitisfixed

securely to the tool.

•Connecttosuitableairsupplyasrecommended.

•Applythesanderlightlytotheworkandallowtheabrasive

disc to cut. Take great care when sanding around sharp

edges and surfaces to avoid the disc snagging i.e. the disc

may be brought to an abrupt stop or considerably slowed,

causing the tool to kick in the hands.

NOTE:

Use of safety glasses and a breathing mask is

recommended. Sanding certain materials may create

hazardous dust which may require special breathing

equipment. Check before using the tool. Although the tool has

a low noise level, the actual sanding process may cause a

noise level such that ear protectors will be required. Safety

gloves are recommended.

Do not continue to use abrasive discs that are worn or clogged.

Do not use undersized or oversized sanding discs. The disc

should be no more than 1/4” larger in diameter than the pad,

and not smaller than the pad.

MAINTENANCE

Lubrication

Air tools require lubrication throughout the lifetime of the tools.

The air motor and bearing uses compressed air to power the tool.

The compressed air contains moisture that will rust the air motor

and other parts in side of the tools, therefore lubrication is required

daily. Failure to lubricate the air tool properly will dramatically

shorten the life of the tool and will void the warranty

CAUTION: This air tool requires lubrication BEFORE initial use,

also before and after each additional use.

WRENCH

B

H