NOTE: Your saw is capable of cutting the following once a special setup procedure is followed.

Refer to Special Cuts.

0° miter Height 1.5" (38 mm) Width 16.1" (409mm)

45º miter Height 1.5" (38 mm) Width 11.7" (297mm)

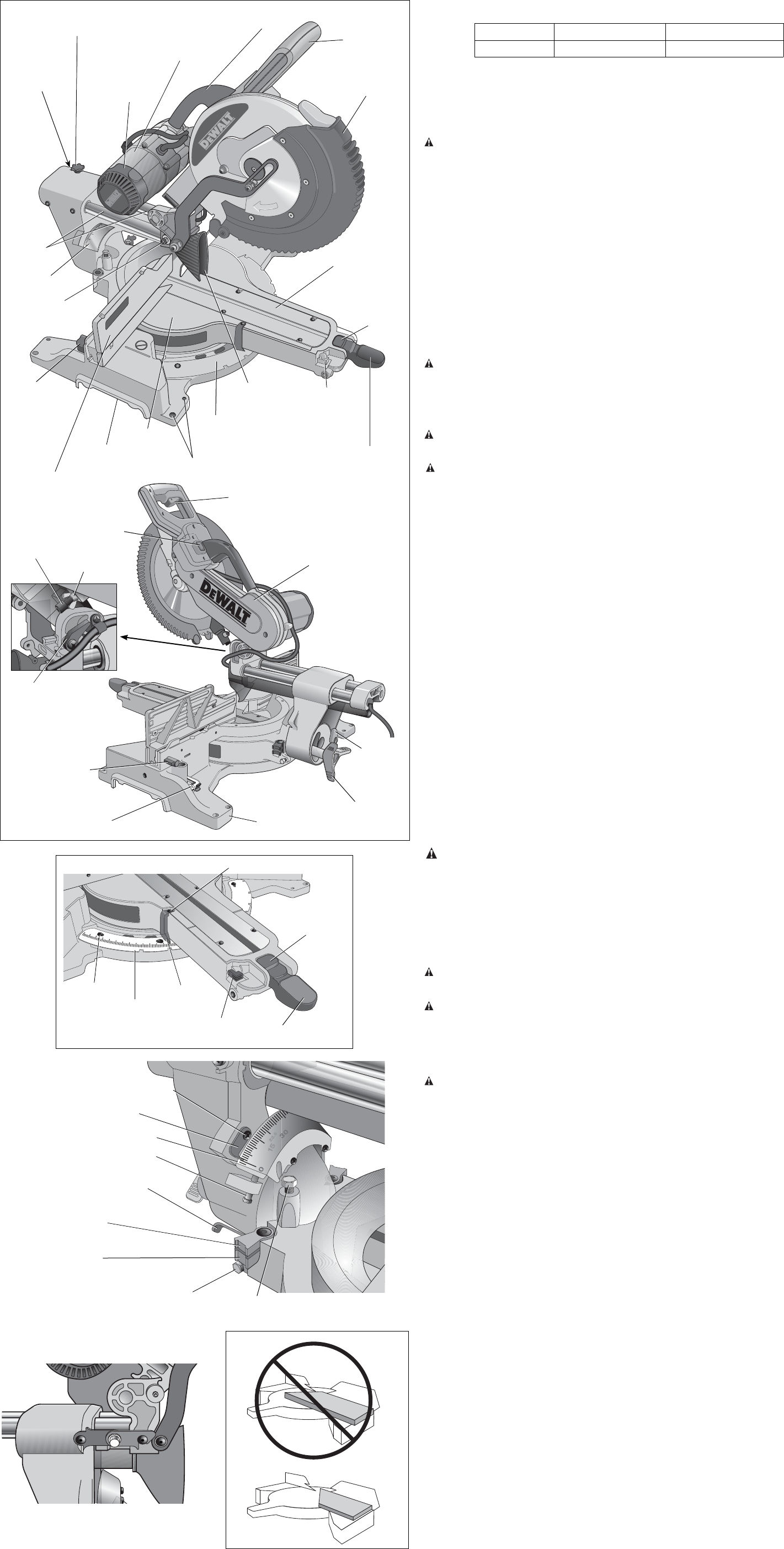

Familiarization

Your miter saw is fully assembled in the car ton. Open the box and lift the saw out by the

con venient lifting handle, as shown in Figure 2.

Place the saw on a smooth, flat surface such as a workbench or strong table.

Examine Figure 4 to become familiar with the saw and its various parts. The section on adjus tments

will refer to these terms and you must know what and where the parts are.

CAUTION: Pinch hazard. To reduce the risk of injury, keep thumb underneath the operating

handle when pulling the handle down. The lower guard will move up as the operating handle is

pulled down, which could cause pinching. The operating handle is placed close to the guard for

special cuts.

Press down lightly on the operating handle and pull out the lock down pin. Gently release the

downward pressure and hold the operating handle, allowing it to rise to its full height. Use the lock

down pin when carrying the saw from one place to another. Always use the lifting handle to transport

the saw, or use the hand indentations shown in Figure 4.

Bench Mounting

Holes are provided in all 4 feet to facilitate bench mounting, as shown in Figure 4. (Two different-

sized holes are provided to accommodate different sizes of screws. Use either hole, it is not

necessary to use both.) Always mount your saw firmly to a stable surface to prevent movement. To

enhance the tool’s portability, it can be mounted to a piece of 1/2" (12.7 mm) or thicker plywood

which can then be clamped to your work support or moved to other job sites and reclamped.

NOTE: If you elect to mount your saw to a piece of plywood, make sure that the mounting

screws don’t protrude from the bottom of the wood. The plywood must sit flush on the work

support. When clamping the saw to any work surface, clamp only on the clamping bosses where

the mounting screw holes are located. Clamping at any other point will interfere with the proper

operation of the saw.

CAUTION: To prevent binding and inaccuracy, be sure the mounting surface is not warped or

otherwise uneven. If the saw rocks on the surface, place a thin piece of material under one saw

foot until the saw sits firmly on the mounting surface.

IMPORTANT SAFETY INSTRUCTIONS

Changing or Installing a New Saw Blade (Fig. 3)

WARNING: To reduce the risk of serious personal injury, turn off the tool and disconnect

it from the power source before attempting to move it, change accessories or make any

adjustments.

CAUTION:

• Never depress the spindle lock button while the blade is under power or coasting.

• Do not cut ferrous metal (containing iron or steel) or masonry or fiber cement product with

this miter saw.

Removing the Blade (Fig. 3)

1. Unplug the saw.

2. Raise the arm to the upper position and raise the lower guard (A) as far as possible.

3. Loosen, but do not remove guard bracket screw (B) until the bracket can be raised far enough

to access the blade screw (E). Lower guard will remain raised due to the position of the guard

bracket screw.

4. Depress the spindle lock button (C) while carefully rotating the saw blade by hand until the lock

engages.

5. Keeping the button depressed, use the other hand and the wrench provided (D) to loosen the

blade screw. (Turn clockwise, left-hand threads.)

6. Remove the blade screw (E), outer clamp washer (F), blade (G) and blade adapter (H), if used.

The inner clamp washer (I) may be left on the spindle.

NOTE: For blades with a blade hole of 5/8" (15.88 mm), the 1" (25.4 mm) blade adapter(H) is not

used.

Installing a Blade (Fig. 3)

1. Unplug the saw.

2. With the arm raised, the lower guard held open and the guard bracket raised, place the blade

on the spindle, onto the blade adapter (if using a blade with a 1" [25.4 mm] diameter blade

hole) and against the inner blade clamp with the teeth at the bottom of the blade pointing

toward the back of the saw.

3. Assemble the outer clamp washer onto the spindle.

4. Install the blade screw and, engaging the spindle lock, tighten the screw firmly with wrench

provided (turn counterclockwise, left-hand threads).

NOTE: When using blades with a 5/8" (15.88 mm) diameter blade hole, the blade adapter will not

be used and should be stored in a safe place for future use. The separate blade adapter is not

available on all models.

5. Return the guard bracket to its original position and firmly tighten the guard bracket screw to

hold bracket in place.

WARNING:

• The guard bracket must be returned to its original position

and the guard bracket screw tightened before activating the

saw.

• Failure to do so may allow the guard to contact the spinning

saw blade resulting in damage to the saw and severe personal

injury.

Transporting the Saw

WARNING: To reduce the risk of serious personal injury, turn off the tool and disconnect

it from the power source before attempting to move it, change accessories or make any

adjustments.

WARNING: To reduce the risk of serious personal injury, ALWAYS lock the rail lock

knob, miter lock handle, bevel lock handle, lock down pin and fence adjustment knobs before

transporting saw.

In order to conveniently carry the miter saw from place to place, a lifting handle has been included

on the top of the saw arm and hand indentations in the base, as shown in Figure 4.

FEATURES AND CONTROLS

WARNING: To reduce the risk of serious personal injury, turn off the tool and disconnect

it from the power source before attempting to move it, change accessories or make any

adjustments.

MITER CONTROL (FIG. 5)

The miter lock handle and miter latch button allow you to miter your saw to 60° right and 50° left. To

miter the saw, lift the miter lock handle, push the miter latch button and set the miter angle desired

on the miter scale. Push down on the miter lock handle to lock the miter angle.

TRIGGER SWITCH (FIG. 4)

The trigger switch turns your saw on and off. A hole is provided in the trigger for insertion of a

padlock to secure the saw.

MITER LATCH OVERRIDE (FIG. 5)

The miter latch override allows your saw to override the common stop angles. To override the

common stop angles, push the miter latch button and flip the miter latch override lever to the

vertical position.

BEVEL LOCK KNOB (FIG. 4)

The bevel lock allows you to bevel the saw 49° left or right. To adjust the bevel setting, turn the knob

counterclockwise. The saw head bevels easily to the left or to the right once the 0° bevel override

knob is pulled. To tighten, turn the bevel lock knob clockwise.

0° BEVEL OVERRIDE (FIG. 4)

The bevel stop override allows you to bevel the saw to the right past the 0° mark.

When engaged, the saw will automatically stop at 0° when brought up from the left. To temporarily

move past 0° to the right, pull the bevel lock knob. Once the knob is released, the override will be

reengaged. The bevel lock knob can be locked out by twisting the knob 180°.

When at 0°, the override locks in place. To operate the override, bevel the saw slightly to the left.

45° BEVEL STOP OVERRIDE (FIG. 6)

There are two bevel stop override levers, one on each side of the saw. To bevel the saw, left or right,

past 45°, push the 45° bevel override lever rearward. When in the rearward position, the saw can

bevel past these stops. When the 45° stops are needed, pull the 45° bevel override lever forward.

CROWN BEVEL PAWLS (FIG. 6)

When cutting crown molding laying flat, your saw is equipped to accurately and rapidly set a crown

stop, left or right (refer to Instructions for Cutting Crown Molding Laying Flat and Using the

Compound Features). The crown bevel pawl can be rotated to contact the crown adjustment

screw. The saw is factory set to be used for typical crown in North America (52/38), but can be

reversed to cut non-typical (45/45) crown. To reverse the crown bevel pawl, remove the retaining

screw, the 22.5° bevel pawl and the 33.86° crown bevel pawl. Flip the crown bevel pawl so the

30° text is facing up. Reattach the screw to secure the 22.5° bevel pawl and the crown bevel pawl.

The accuracy setting will not be affected.

FIG. 4

FIG. 6

22.5º BEVEL PAWL

(one each side)

BEVEL POINTER

(one each side)

0° BEVEL ADJUSTMENT

SCREW

BEVEL POINTER SCREW

(one each side)

BEVEL SCALE

CROWN ADJUSTMENT SCREW

(one each side)

45° BEVEL OVERRIDE LEVER

(one each side)

CROWN BEVEL

PAWL

(one each side)

45° BEVEL

ADJUSTMENT SCREW

(one each side)

KERF

PLATE

MOTOR

HOUSING

RAIL SET

SCREW

ADJUSTMENT

RAIL LOCK

KNOB

MOTOR

ENDCAP

BEVEL SCALE

LOCK DOWN

PIN

MITER

LATCH

BUTTON

TABLE

MITER LATCH

OVERRIDE

MITER

SCALE

MITER LOCK

HANDLE

FENCE

ADJUSTMENT

KNOB

(one each side)

BENCH MOUNTING HOLES

LIFTING

HANDLE

DUST DUCT

INLET

FENCE

HAND

INDENTATION

RAILS

OPERATING

HANDLE

LOWER

GUARD

BELT COVER

BEVEL LOCK

KNOB

TRIGGER

SWITCH

0° BEVEL

STOP

WING NUT

DEPTH

ADJUSTMENT

SCREW

DEPTH STOP

FENCE

ADJUSTMENT

KNOB

(one each side)

BLADE WRENCH

XPS

TM

ON/OFF

SWITCH

BASE

FIG. 5

MITER

POINTER

MITER

SCALE

SCREW

(4 places)

MITER POINTER SCREW

MITER

LATCH

BUTTON

MITER LOCK

HANDLE

MITER LATCH

OVERRIDE

FIG. 8

FIG. 7