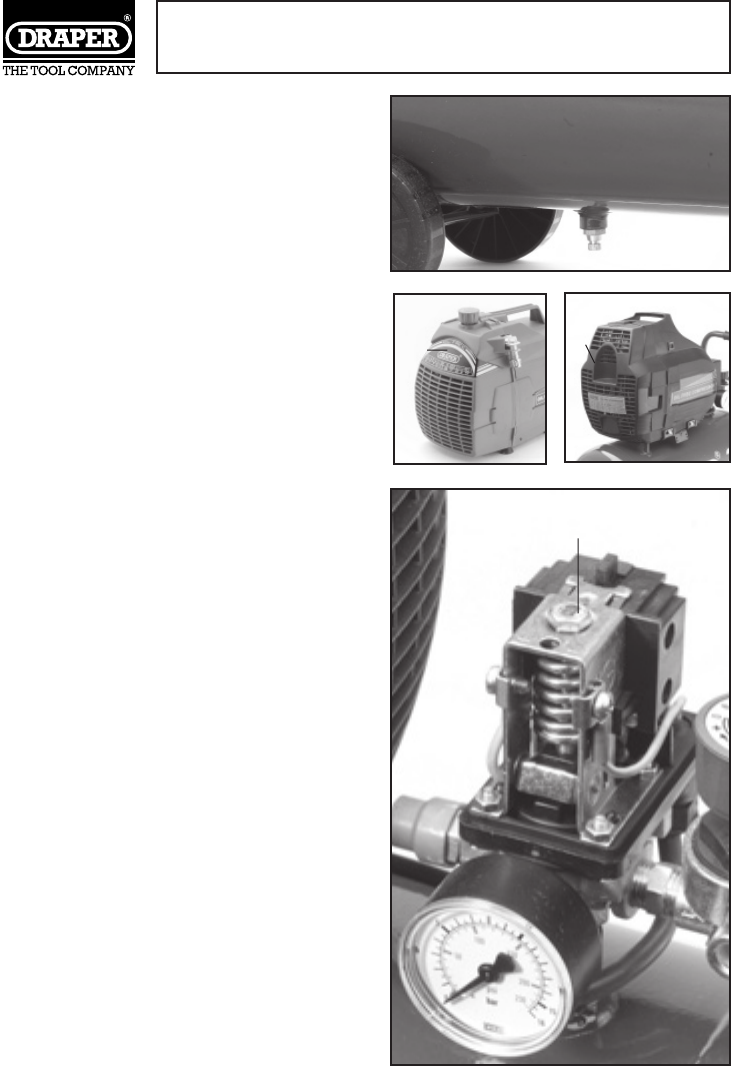

Fig.6.

(J)

(K)

Fig.5.

IMPORTANT:

Before performing any maintenance

operations, disconnect the compressor from

the power supply and release all the air from

the receiver, until the pressure gauge reads

zero.

EVERY DAY:

Drain the condensate from the receiver. The

drain (H) Fig. 5. is situated on the underside

of the receiver tank for the DA25/200,

DA25/180 and on the end of the tank for the

DA6/200.

EVERY MONTH:

Clean the air suction filter using compressed

air. Replace the filter every 50 hours of use.

EVERY 100 HOURS:

Clean all the external surfaces of the pump

unit and motor. Ensure that neither the motor

fan cowling (J) or head cooling fins are

blocked or obstructed in any way. See Fig.6.

EVERY 200 HOURS:

Check the condition of the valves and replace

them if they are damaged or worn.

PRESSURE SWITCH SETTINGS (DA6/200,

DA6/201, DA25/180, DA25/200):

The delivery pressure setting can drift over

a period of time and will require periodic

adjustment. Ensure that the pressure switch

settings are correctly adjusted and maintained

at the correct level. This will help prevent

faults occurring which can result in reduced

performance and possible failure.

PRESSURE SWITCH ADJUSTMENTS

(DA6/200, DA6/201, DA25/180, DA25/200):

To adjust the pressure level at which the cut-

out and cut-in functions, remove the switch

cover and turn the pressure regulating screw

(K) clockwise to increase the level and

anticlockwise to decrease the level. See Fig.7.

WARNING:

DO NOT ADJUST THE CUT-OUT PRESSURE

ABOVE THE MAXIMUM PRESSURE AS PER

THE MACHINE SPECIFICATION.

(J)

Fig.6.

- 7 -

MAINTENANCE