- 6 -

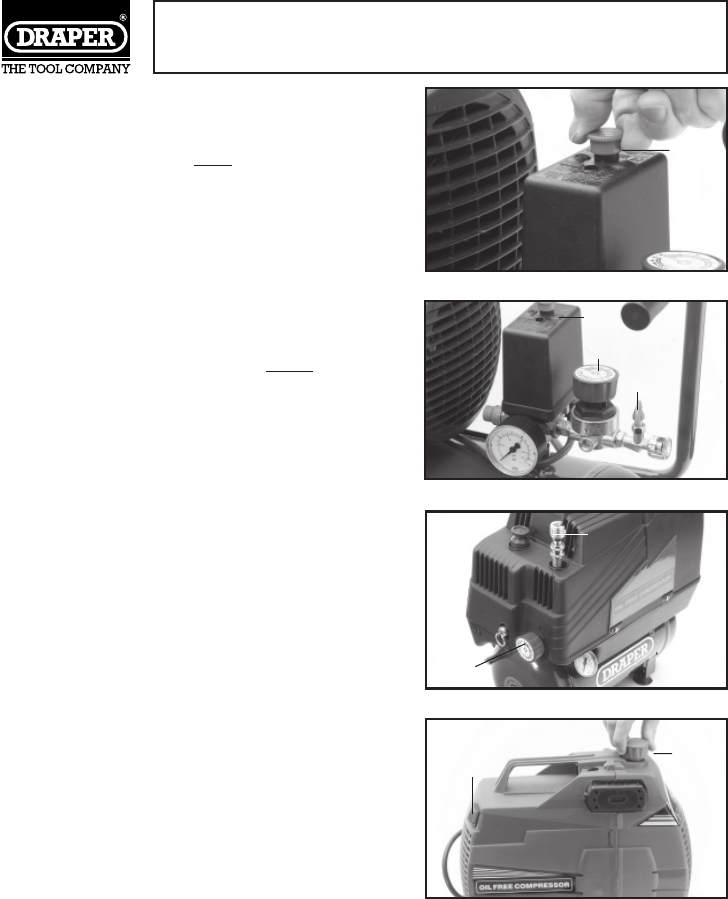

Fig.1.

Fig.2.

Fig.3.

(A)

(B)

(D)

(C)

(L)

(K)

Fig.4.

(G)

(F)

Connect the compressor to the power supply.

Always turn on and off by the appropriate switch.

TURNING ON AND OFF (DA6/200/DA6/201,

DA25/180, DA25/200 - NOT DA200): THE ON/

OFF SWITCH.

(A) Fig.1. is located on the top of the pressure

switch box.

These compressors are controlled by a pressure

switch assembly (B) Fig.2. which automatically

cuts off the power supply to the motor when

the upper limit is reached and restarts the

compressor automatically when the pressure

drops below the minimum.

TURNING ON AND OFF (DA200 ONLY):

This compressor is operated by a manual

on/off switch (F) Fig.4. and NOT by an

automatic pressure switch as fitted to the other

compressors shown in this booklet.

WARNING (DA6/200/DA6/201, DA25/180,

DA25/200):

The pressure switch is set at the factory and the

compressor is also fitted with a safety valve in

the event of the pressure switch not functioning

correctly.

SETTING THE REQUIRED AIR PRESSURE:

DA25/180, DA25/200

Close the air outlet valve (C) Fig.2. and adjust

pressure by turning the knob on the pressure

regulator valve (D) Fig.2. clockwise to increase

pressure. Should it be necessary to decrease

pressure open the the air outlet valve (C) Fig.2.

slightly and then turn the pressure regulator

valve knob (D) anticlockwise, re-close air outlet

valve (C).

DA200

This compressor is fitted with a pressure

regulator unit (G) Fig.4. so the pressure may be

regulated as necessary. To increase the pressure

turn the knob clockwise, to decrease the

pressure turn the knob anticlockwise.

DA6/200

Close the air outlet valve (K) Fig.3. and adjust

pressure by turning the knob on the pressure

regulator valve (L) Fig.3. clockwise to increase

pressure. Should it be necessary to decrease

pressure open the the air outlet valve (K) Fig.3.

slightly and then turn the pressure regulator

valve knob anticlockwise, re-close air outlet

valve.

COMPRESSOR OPERATION