5

Wear hearing protection.

Wear eye protection.

Wear respiratory protection.

Read the instruction manual

BEFORE USING THIS AIR TOOL

OPERATING INSTRUCTIONS

This ratchet is designed to speed up productivity, not for high torque applications such as head bolts, lug

nuts, etc. DO NOT USE THIS RATCHET UNDER POWER TO BREAK FASTENERS LOOSE. Loosen

fasteners by hand without depressing throttle. Once loose depress throttle. Always perform nal torque

tightening by hand.

This ratchet is rated to 3/8” bolt size. Rating will decrease for U-bolts, long cap screws, spring fasteners

and rusted or corroded fasteners. All these factors absorb power and reduce torque capability.

Use the simplest socket to wrench hook-up. Any additional extensions, U-joints or adapters will absorb

power and reduce torque capability.

Forward/Reverse Lever - Select “F” for forward (clockwise) or “R” for reverse (counter clockwise) opera-

tion. Do not attempt to change direction while tool is running.

If fastener bogs, slows or binds the tool (or, if the fastener fails to move in 5 seconds), use a large size

impact wrench with a higher torque rating. Overloading this tool will cause premature wear and/or per-

manent damage to internal and external drive parts and will void warranty.

To ensure long life be sure to oil the tool daily. Pour 4 drops of Eagle air tool (SEA 20 non

detergent) oil into the air inlet, and then run the tool for a few seconds to clean.

If tool is an impact wrench tted with a “Zirc” grease tting:

The hammer mechanism of this tool also needs to be greased from time to time (depending

on usage). The tool is equipped with grease tting for this purpose; use this connection to

re-grease the tool using Eagle impact wrench grease.

PLEASE USE EAGLE SEA 20 NON DETERGENT OIL

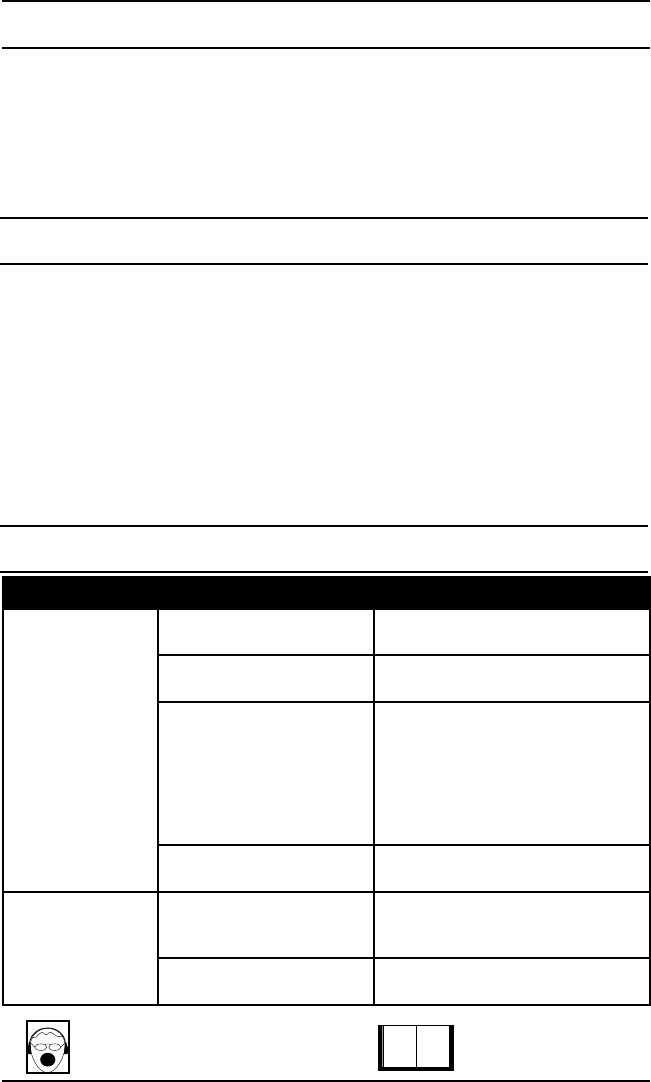

TROUBLESHOOTING

SYMPTOMS CAUSE REMEDY

Air tool does not

run or runs slow.

Lack of lubrication. Lubricate as per instructions.

Dirt in tool. Clean with mixture of 50/50 tool

oil/solvent. Lubricate after cleaning.

Insufcient air pressure. Check regulator and air supply for

leaks. Check compressor to make

sure it operates at correct pressure.

Make sure air hose is properly sized

and that multiple hoses are not

connected to same outlet. Check air

hose for leaks and repair.

Rotor blades worn or motor

bearing worn or dirty.

Replace blades, inspect clean or

replace bearing.

IMPACT WRENCH

does not impact or

impacts slowly.

See causes (above). See remedies (above).

Broken or worn impact

mechanism.

Inspect and repair as required.