5

Wear hearing protection.

Wear eye protection.

Wear respiratory protection.

Read the instruction manual

BEFORE USING THIS AIR TOOL

OPERATING INSTRUCTIONS

Do not put additional pressure on the tool, this will only reduce efciency and shorten the

tool’s life. We recommend the air pressure of this grinder at 90 PSI.

When using the grinder be careful not to exert excessive force. Too much force could be

hazardous if it caused the cutting tool spindle to bend or break.

The burning of the work piece or excessive speed reduction indicates too much force being

applied. Changing to a cutting tool may be better for the desired rate of speed and stock

removal.

Avoid hazardous conditions by making sure there is sufcient gripping force on the spindle

of cutting tool by placing the spindle 7/16” or more inside the collet.

Lubricate the motor with a good grade of air tool oil. Grit or gum deposit in the tool may cut

power and may be corrected by cleaning the air strainer and ushing out the tool with gum

solvent oil.

To ensure long life be sure to oil the tool daily. Pour 4 drops of Eagle air tool (SEA 20 non

detergent) oil into the air inlet, and then run the tool for a few seconds to clean.

If tool is an impact wrench tted with a “Zirc” grease tting:

The hammer mechanism of this tool also needs to be greased from time to time (depending

on usage). The tool is equipped with grease tting for this purpose; use this connection to

re-grease the tool using Eagle impact wrench grease.

PLEASE USE EAGLE SEA 20 NON DETERGENT OIL

TROUBLESHOOTING

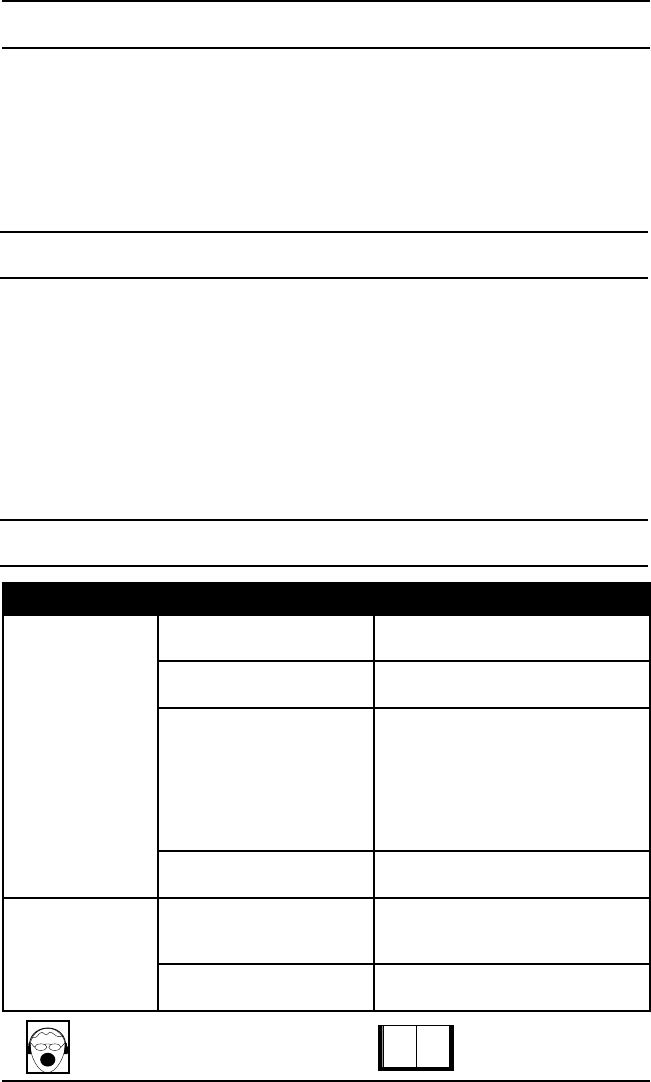

SYMPTOMS CAUSE REMEDY

Air tool does not

run or runs slow.

Lack of lubrication. Lubricate as per instructions.

Dirt in tool. Clean with mixture of 50/50 tool

oil/solvent. Lubricate after cleaning.

Insufcient air pressure. Check regulator and air supply for

leaks. Check compressor to make

sure it operates at correct pressure.

Make sure air hose is properly sized

and that multiple hoses are not

connected to same outlet. Check air

hose for leaks and repair.

Rotor blades worn or motor

bearing worn or dirty.

Replace blades, inspect clean or

replace bearing.

IMPACT WRENCH

does not impact or

impacts slowly.

See causes (above). See remedies (above).

Broken or worn impact

mechanism.

Inspect and repair as required.