5

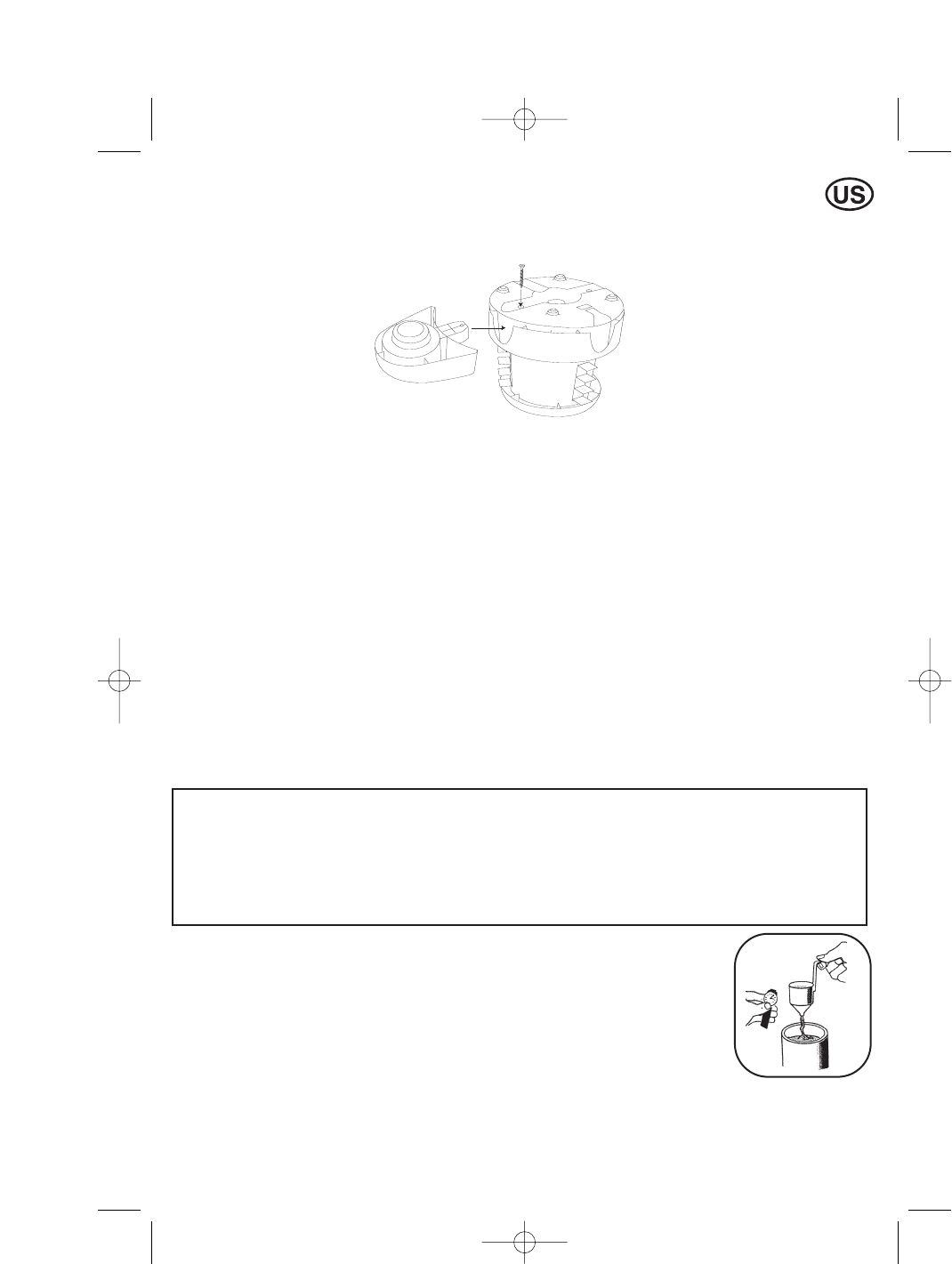

FITTING THE POD

Fit the pod moulding (L0021) to the motor housing by pushing it into the recess in the base until it clicks into

place. The pod is secured with the screw (L0116) provided. (Below)

PREPARATION

Preparation of the surface and thinning of the paint are the two most important areas to be concerned with to

obtain the best results from your spray kit.

Ensure all surfaces are free from dust, dirt, rust and grease. If necessary rub down with sandpaper, or similar.

Masking of areas is important to ensure you do not spray those areas you wish to remain untouched.

THINNING

Your spray kit is supplied with a viscosity cup. Viscosity is a technical term used to indicate if a product is very

thin or very thick. If thin, the viscosity is said to be low, while if very thick the viscosity is said to be high.

Viscosity is measured in seconds. In order to spray some materials they need to be “thinned” (diluted).

Thinning is very important when spraying. Most paints etc are supplied ready for brush application and may

need to be thinned (diluted) for spraying purposes. Follow the manufacturers guide for thinning in conjunction

with a spray gun. If in doubt please contact the manufacturers of the paint. The viscosity cup supplied will help

you determine the correct thickness of the paint. Paint is “thinned” by adding the substance which the paint

is based upon. If a water based paint then water is added, if oil based then white spirit.

As some paints, wood preservatives and other sprayable materials contain particles that have differing

qualities, please ensure that when filling the paint container of the spray gun, that the paint is filtered through

either a funnel with a filter on it or through nylon tights or stockings. This will ensure that no large particles enter

the paint container, so preventing blockages and providing you with trouble free spraying. Ensure that a face

mask, gloves and goggles are worn at all times when spraying.

IDEAL VISCOSITY

Water based paints and latex 25 - 60 seconds

Oil based paints 45 - 50 seconds

Wood preservatives No dilution

Primers 45 - 50 seconds

Varnishes No dilution

Aluminium paints No dilution

Wood stains No dilution

Automotive Paint Manufacturer

’

s ratio

This gun can be used with products having a viscosity ranging from 25 to 60 seconds.

Dip the viscosity cup into the material and fill up.

T

ime how long it takes for the viscosity

cup to empty (Fig. 1)

Using the above chart (or manufacturer

’

s instructions) as a guide determine if the

material requires further thinning, if so then thin accordingly

.

If the paint requires thinning, start with a 10% dilution of the paint.

To do this, fill a 1litre

container with the required paint.

The viscosity cup supplied with the unit holds 1/10 of a

litre, block the hole in the viscosity cup and fill up with the required thinner

. Add the

thinner to the paint and stir

, measure the viscosity using the recommended viscosity chart

above.

If the paint requires further thinning, dilute the paint by another 5% (5% will be equal to half a viscosity cup)

with the required thinner and measure the viscosity

, if the paint is not at it's recommended viscosity, repeat the

above step.

Note: Some paints are outside the ranges listed above. Please contact our helpline for further information.

Fig. 1

L0553 (04-08) (US-FR-ES).qxd 20/6/08 2:25 pm Page 5