12

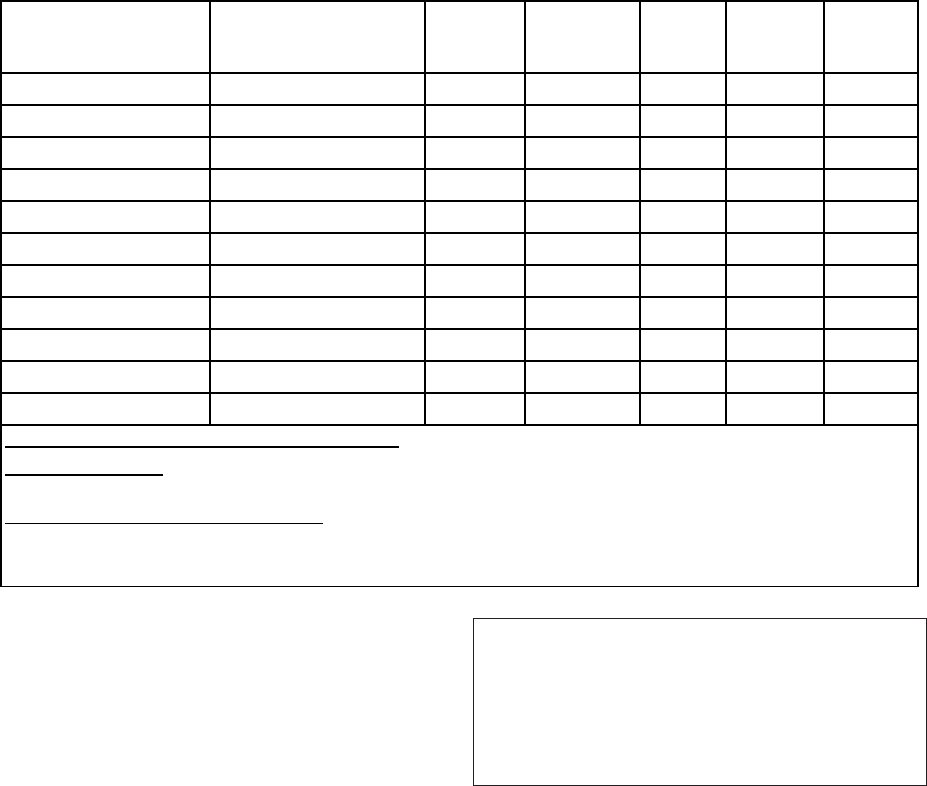

MAINTENANCE AND CARE

IMPORTANT

Time intervals are maximum. Actual use and

your experience will determine the frequency

of required maintenance.

Record dates of monthly and yearly

inspections.

COMPONENT / SYSTEM

MAINTENANCE

PROCEDURE

REQ'D

SKILL

LEVEL

DAILY OR

BEFORE USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY

600 HOURS

Air Filter Inspect/Clean

1I / C * R *

Choke Shutter Inspect/Clean

1I / C

Fuel Filter Inspect/Replace

1 I * I / R *

Fuel Cap Gasket Inspect/Replace

1I *R

Fuel System Inspect/Replace

1 I (1) * I (1) *

Spark Plug Inspect/Clean/Replace

1 I / C / R *

Cooling System Inspect/Clean

2I / C

Muffler Spark Arrestor Inspect/Clean/Replace

2 I / C / R *

Cylinder Exhaust Port Inspect/Clean/Decarbon

2I / C

Recoil Starter Rope Inspect/Clean

1I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace

1I *

* All recommendations to replace are based on the finding of damage or wear during inspection.

MAINTENANCE PROCEDURE LETTER CODES:

I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE

- Time intervals shown are maximum. Actual use and your experience will determine the

frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.