5

Troubleshooting

PROBLEM PROBABLE CAUSE SOLUTION

Off-scale reading

Wiring is wrong. Verify wiring.

RTD is open or shorted. Check RTD for open or short circuits.

See Figure 11.

Sensor is not in process stream. Be sure sensor is completely submerged in

process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Sensor has failed. Perform isolation checks. See Figure 12.

Noisy reading

Sensor is improperly installed in

process stream.

Be sure sensor is completely submerged in

process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Reading seems wrong (lower or

higher than expected)

Bubbles trapped in sensor. Be sure sensor is properly oriented in pipe or

ow cell. See Figure 1. Apply back pressure to

ow cell.

Wrong temperature correction

algorithm.

Check that temperature correction is

appropriate for the sample. See analyzer

manual for more information.

Wrong cell constant. Verify that the correct cell constant has been

entered in the analyzer and that the cell

constant is appropriate for the conductivity of

the sample. See analyzer manual.

Sluggish response

Electrodes are fouled. Clean electrodes.

Sensor is installed in dead area in

piping.

Move sensor to a location more

representative of the process liquid.

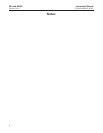

Figure 11. Checking RTD

Disconnect leads and measure resistances shown. The

measured resistance at room temperature should be

close to the value in the table.

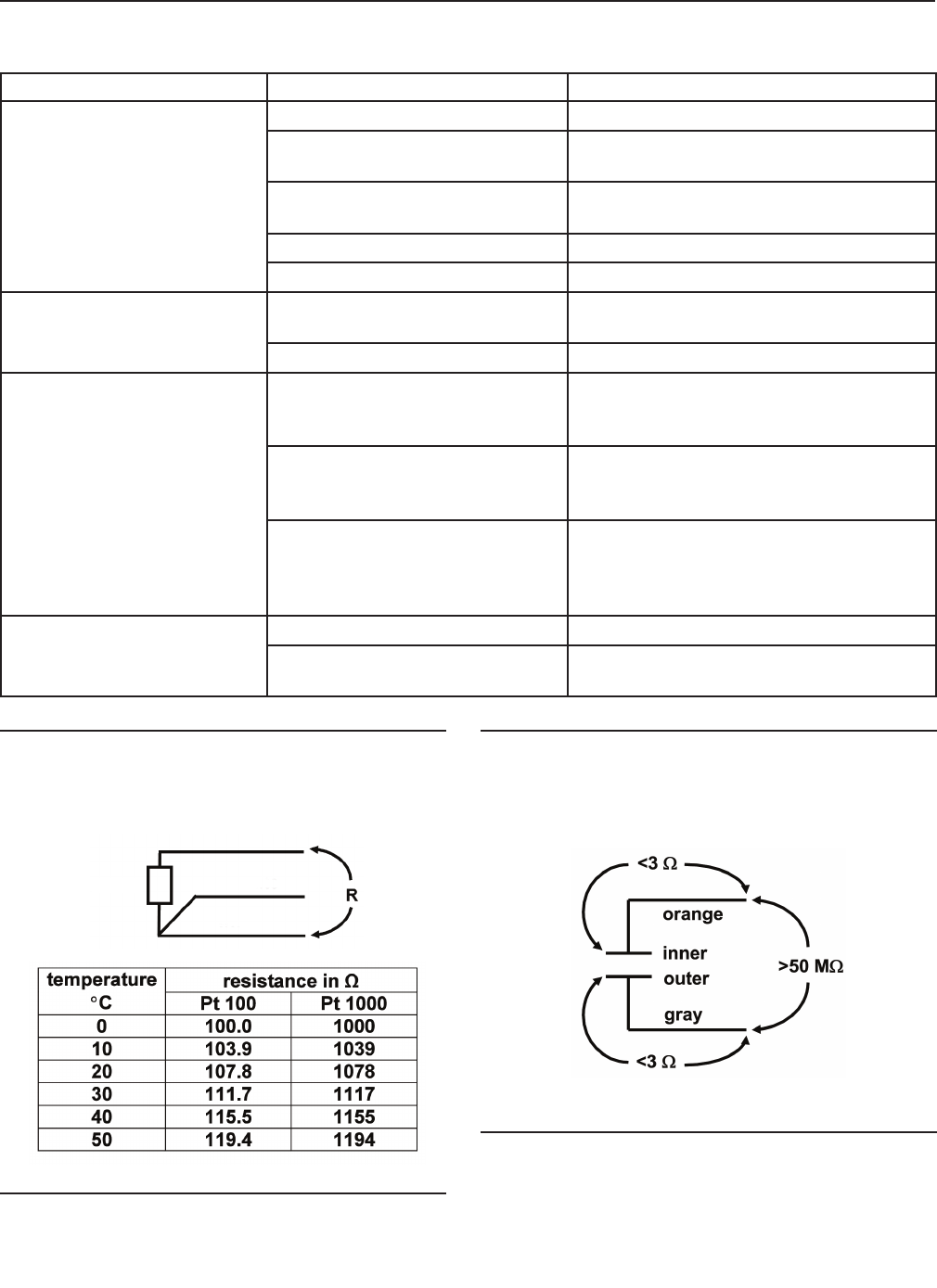

Figure 12. Checking Continuity and Leakage

Disconnect electrode leads and measure resistance

and continuity as shown. Sensor must be dry when

checking resistance between electrode leads.

red/white

RTD

white

red

Instruction Manual 403 and 403VP

LIQ-MAN-ABR-403-403VP February 2015