3

Even with all these built-in features, you’ll still fi nd the 450XL to be

extremely cost-effi cient. This compressor has a whopping cylinder

displacement of 84,5 m

3

/h while running at 1200 RPM. And the

high isentropic effi ciency of the 450XL means its COP is second to

none when compared to other compression systems.

The 450XL can be installed almost anywhere, even on an upper

fl oor if necessary, since vibration is kept to a minimum. Noise level

is low too, due to the use of quickacting, precise ring plate suction

and discharge valves.

Far-Reaching Applications

The 450XL is so versatile it can handle almost any refrigeration

system conditions. Up to 24.1 bar maximum discharge, and up

to 10.3 bar maximum suction with a maximum 17.2 bar pressure

differential. At different compression ratios, too, from 8:1 for am-

monia to 14:1 for R404A. In V-belt confi gurations all the way up to

224 kW, or

direct drive setups up to 285 kW. And it’s usable for both 50Hz and

60Hz applications up to 1200 RPM.

The graph (Figure 2) on the next page depicts the broad range of

applications that the 450XL covers.

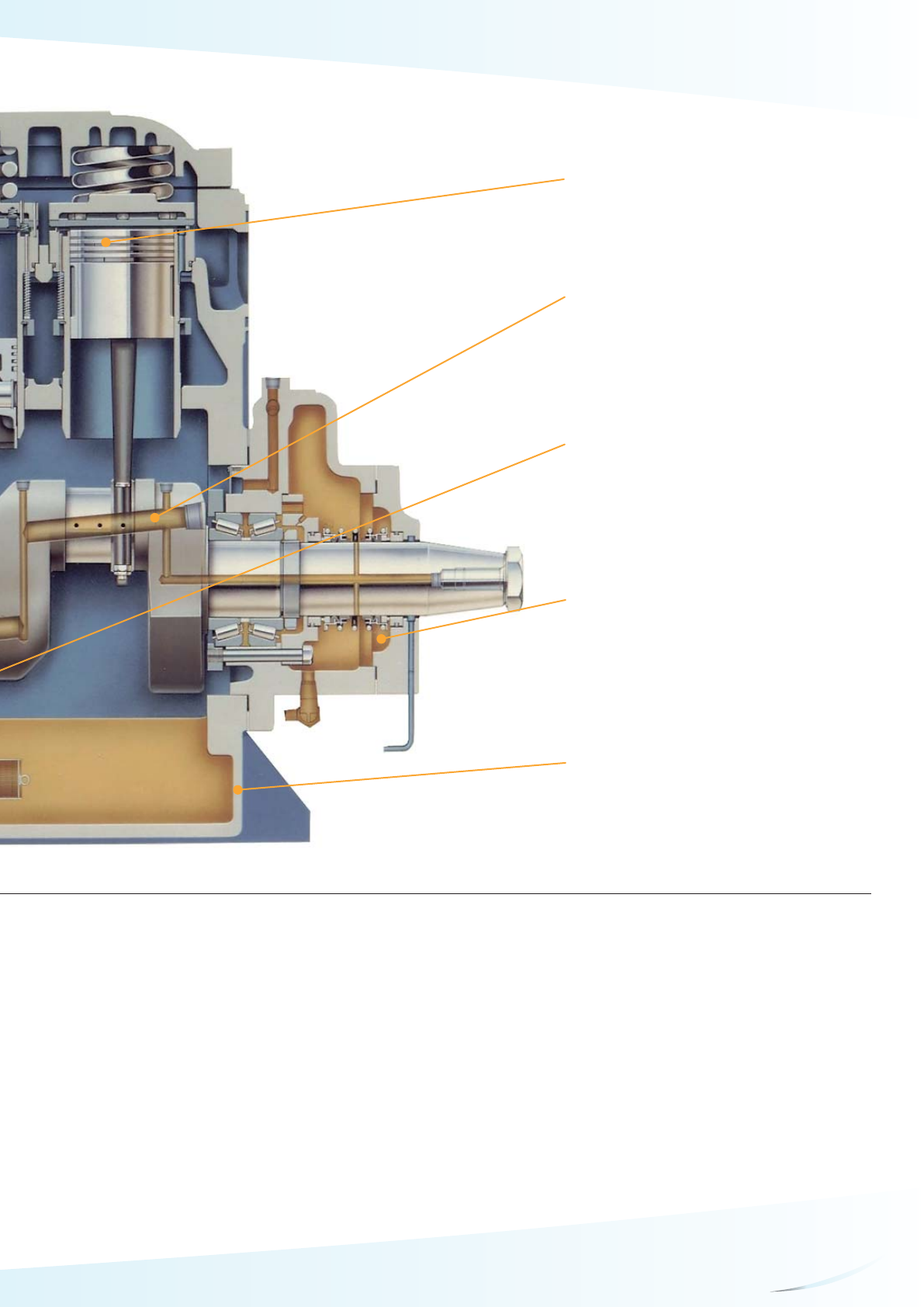

Compression and Oil Rings

The 450XL piston ring set consists of three compres-

sion rings and a single, special oil scraper ring for

keeping oil consumption to an absolute minimum.

Heavy-Duty Crankshaft*

An over-sized crankshaft pin diameter provides years

of rugged, dependable duty, while the larger bearing

surface allows for higher pressure differential capabi-

lities.

Connecting Rod Bearings*

Vilter’s unique oil circuit drilling arrangement ensures

proper hydrodynamic lubrication of insert bearings

throughout the entire compression process. Rod

bearings are specially designed to supply lubrication

to the piston pin bushing at all times.

Double Bellows Shaft Seal

The 450XL shaft seal, designed to specifi c Vilter

specifi cations, is manufactured from materials strictly

used for industrial refrigeration applications. Seal unit

assembly consists of two opposed seals – one sealing

from the atmosphere and the other from the crank-

case. Mating seal surfaces are lubricated and cooled

by circulated oil.

Single Casting Frame

The single casting frame incorporates suction and

discharge manifolds plus bearing supports. It’s cast to

exacting tolerances from a high grade of cast iron to

withstand extreme changes in heat and pressure. The

castings are notably free from porosity and internal

strains, and display excellent wearing qualities.

*Patented Design