23

MODEL 399VP pH/ORP SENSOR SECTION 6.0

TROUBLESHOOTING

SECTION 6.0.

TROUBLESHOOTING

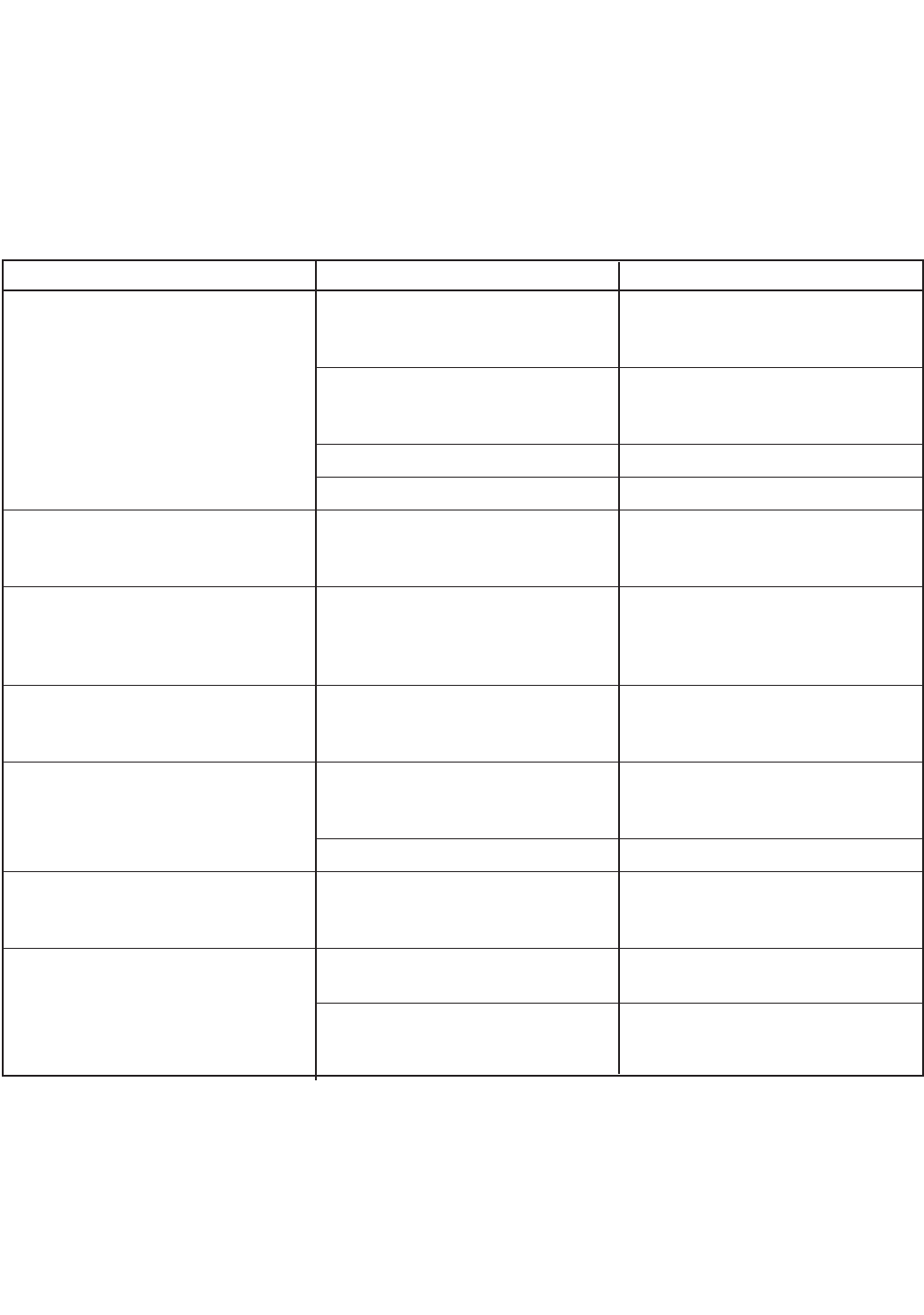

TROUBLESHOOTING. The table below lists common problems, causes and remedies typically encountered in

process measurement.

Problem Probable Cause Remedy

Meter reads off scale (display T.C. element shorted. Check T.C. element as instructed

reads overrange). in Section 5.2 and replace

sensor if defective.

Sensor not in process. Sample Make sure sensor is in process with

stream is low or air bubbles are sufficient sample stream (refer to

present. Section 2.0 for installation details).

Open glass electrode. Replace sensor.

Reference element open - no contact.

Replace sensor.

Display reads between 3 and 6 pH, Electrode cracked. Replace sensor.

regardless of actual pH of solution

or sample.

Meter or display indication swings T.C. element shorted. Check T.C. element as instructed

or jumps widely in AUTO T.C. Mode. in Section 5.2 and replace

sensor if defective.

Span between buffers extremely T.C. element open. Check T.C. element as instructed

short in AUTO T.C. Mode. in Section 5.2 and replace sensor

if defective.

Sluggish or slow meter indication Electrode coated. Clean sensor as instructed in

for real changes in pH level. Section 5.3. Replace sensor if

cracked.

Electrode defective. Replace sensor.

Transmitter cannot be standardized. Electrode coated or cracked. Clean sensor as instructed in

Section 5.3. Replace sensor if

cracked.

Transmitter short spans between Aged glass electrode or high Replace sensor.

two different buffer values. temperature exposure.

Electrode coated . Clean sensor as instructed in

Section 5.3. Replace sensor if

cracked.