SERVICE CHECK

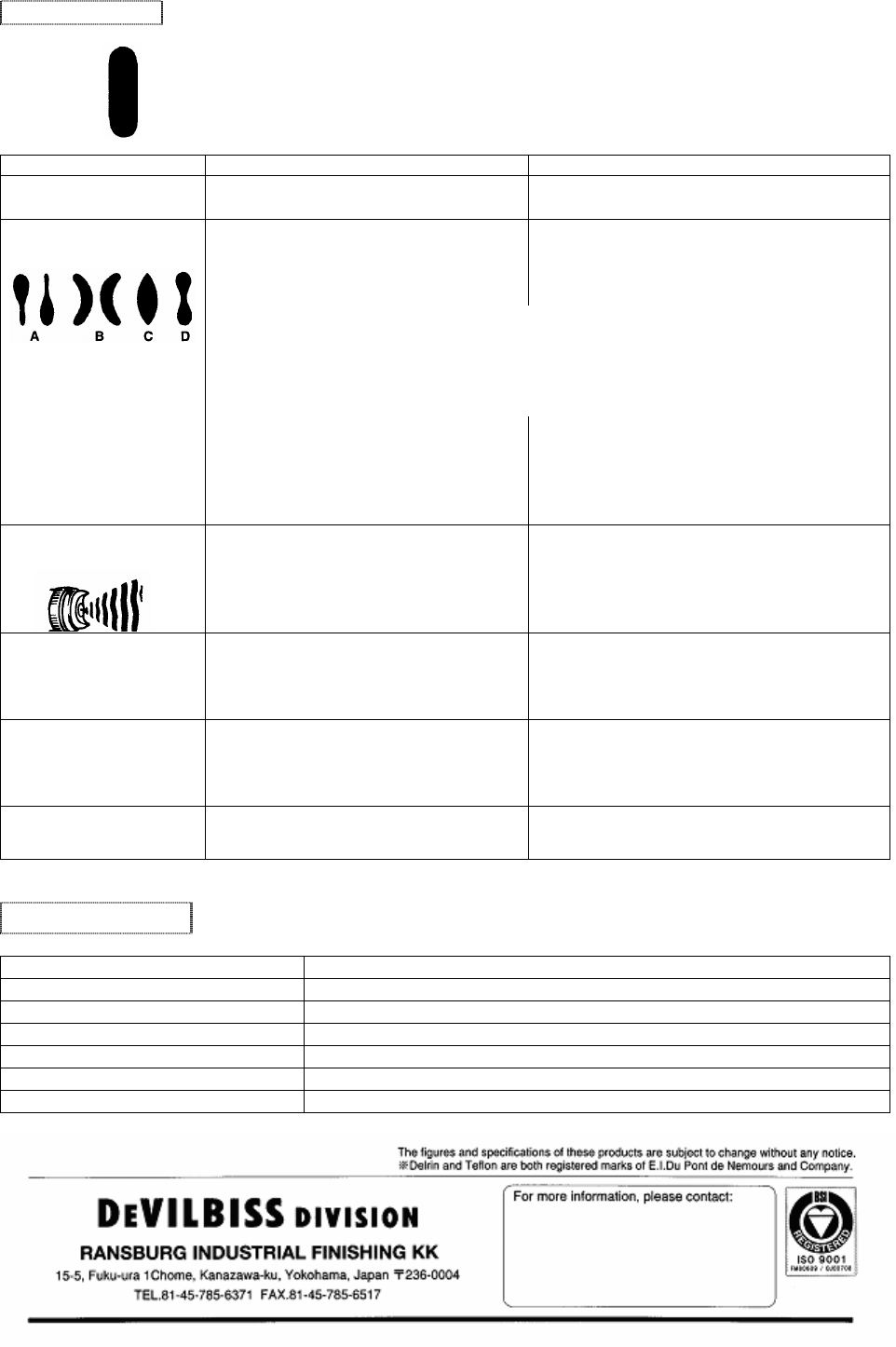

Normal Spray Pattern

The proper combination of fluid pressure, fan and atomization air pressure,

and fluid tip size should result in a pattern of this shape.

PROBLEM CAUSE CORRECTION

Will not spray. No pressure to gun.

Piston stops moving.

Check air and material lines.

Check CYL air pressure.

A. Gun not adjusted properly.

A, B Material build up on the air

cap (2)or fluid tip (3).

A. Re-adjust. See “Operation

Section”.

A, B Clean the air cap or fluid tip.

See “Preventive Maintenance”.

Note

To determine where the material build up is, rotate the air cap 180 and test

spray. If the pattern stays in the same position, the condition is caused by

material build up on the fluid tip. If the pattern changes with air cap movement,

the build up is in the air cap.

Improper spray

pattern.

C, D. Wrong material or material

too thick.

Insufficient material or

atomizing air pressure too

high.

C, D Adjust material pressure or thin

material.

Increase material or reduce

atomizing air pressure.

Jerky or fluttering

spray.

1.

2.

3.

4.

1.

2.

3.

4.

Insufficient material in the tank

or an obstruction in the line.

Gun material passage plugged.

Worn Needle Seal Kit (7).

Loose or damaged fluid tip.

Fill tank or clear obstruction.

Clean.

Replace.

Tighten or replace.

Air leaking from

Adjusting Screw (20).

1.

2.

1.

2.

Damaged or worn Piston Cup

(14).

Damaged cylinder of Gun Body

(6).

Replace.

Replace.

Dripping from Fluid

Tip.

1.

2.

3.

1.

2.

Worn or damaged Fluid Tip (2)

or Needle (12).

Needle Spring (18) damaged or

deformed.

Replace.

Replace.

Air or fluid leaking

from Gun Body (6).

Damaged or worn Needle Seal Kit

(7)

Replace.

ACCESSORIES

PART NUMBER DESCRIPTION

SSL-10 Gun Lube (60ml)

42884-214-K5 Cleaning Brush (Kit of 5)

AGA-415 Universal Clamp

GC-100-K48 Gun Cover (Kit of 48)

HD-505 Quick Cleaner (5L)

QMGZ-5200 Solvent Saver (10L)

7