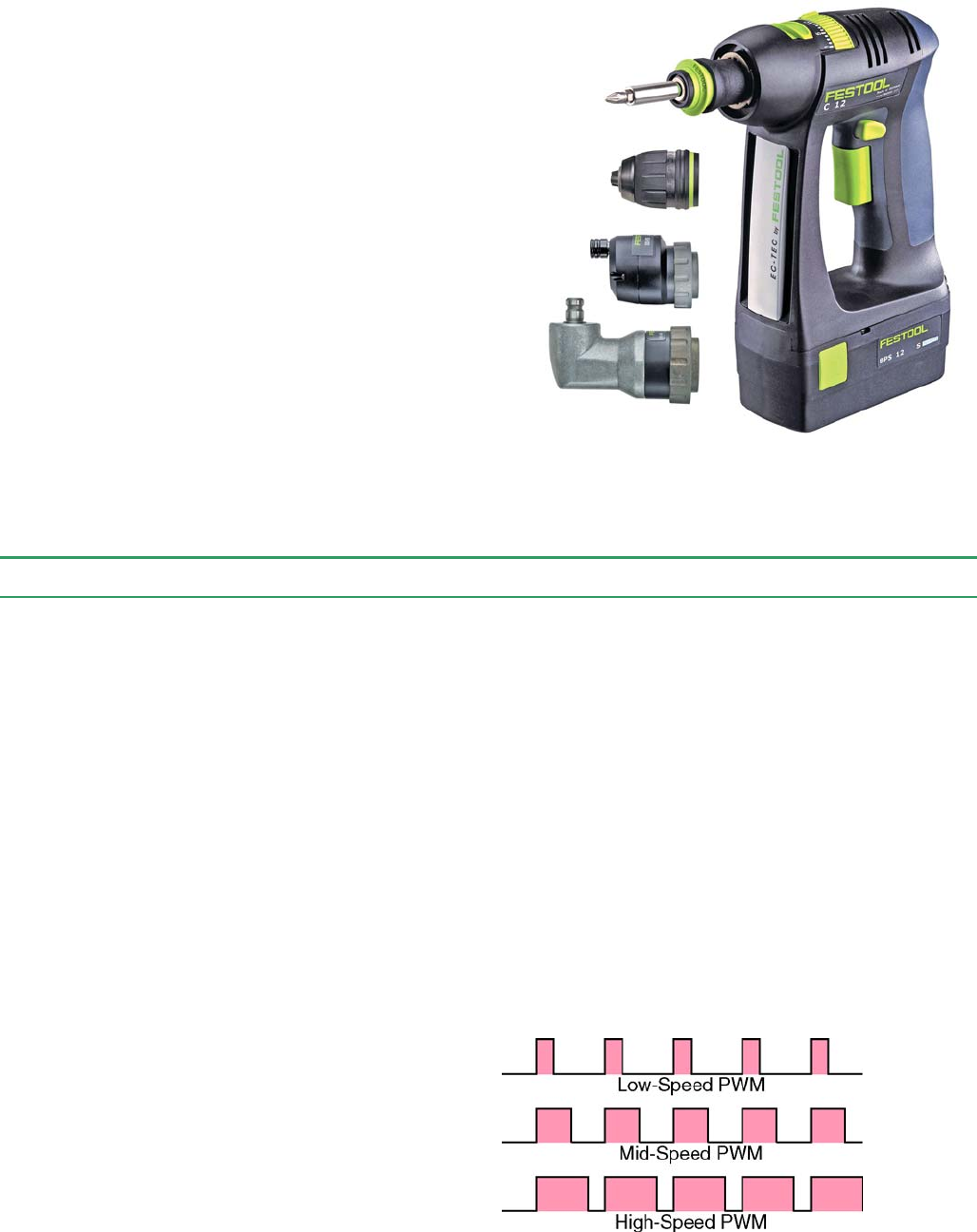

► The C12 comes with the compact Centrotec bit

holder, as shown, but also includes the

standard keyless chuck (top image of the three

attachments). The optional offset and right-

angle chucks (lower two images) are awe

inspiring, and are a "must have" accessory in

my opinion.

My Background: I am an electrical engineer, and my

current occupation is Sr. Technical Writer for an

international corporation. I use my engineering

background to write technical repair manuals for

sophisticated equipment, including such things as

lasers, robotic systems, and smartcard programmers,

to name a few.

In the past, I owned and operated a custom cabinet

shop, and am the true definition of a "tool junkie". I

also use to perform "tool tests" for several

woodworking magazines.

A year ago I was introduced to Festool products, and

was so impressed with them that I began rewriting

some of their owner's manuals in my spare time.

Supplement: How Variable Speed Controllers Work

A common misconception about variable speed

tools is that the speed is controlled with a variable

resistor, like the dimmer of a light switch. This

doesn’t work well for motors for two reasons.

First, is because energy is wasted pumping current

through the resistor. The second reason is that

whatever power that is not being used by the

motor has to be dissipated by the resistor. This

means that the battery would be providing full

power at all times, regardless how slow the motor

is turning. This would be like driving your car

with the gas pedal pressed all the way to the floor,

and trying to drive at the speed limit by constantly

pressing the brake pedal.

A more efficient way to control the speed of a

motor is to turn it on and off very rapidly. The

more the motor is turned on, versus turned off, the

faster it spins. Keep in mind that this switching is

happening so fast (several hundred times a

second) that the inertia of the motor keeps it

spinning smoothly.

This type of motor speed control is called Pulse

Width Modulation (PWM), and is also used in many

other applications to control power. Most recently,

even the old resistive light dimmers are being

replaced by solidstate PWM light dimmers,

because they are more efficient and do not pose a

fire hazard from overheating.

With a PWM motor control, the power pulses turn

on at a constant interval, but the duration of the

pulse is varied, as shown below. The longer the

pulses, the more current flowing through the

motor, and the faster it spins. When full power is

needed, the PWM circuitry is bypassed, and full

battery power is delivered to the motor.

5