3

Symbols

n

0

no load speed (revolutions)

rpm revolutions per minute

opm orbits per minute

Use for intended purpose

As specified, the machines are designed for

sanding wood, plastic, metal, stone, composite,

paintwork, filler and similar materials. Material

containing asbestos must not be processed with

these tools.

The user is liable for any damage

and injury resulting from incorrect usage!

Functional description

Connection and start-up

Make sure that the pneumatic

tool is switched off when you connect the

compressed-air supply.

Compressed-air treatment

The Festool service unit should always be used

to ensure that Festool pneumatic tools function

correctly. Consisting of a filter, control unit,

condensation drain and lubricator, the service

unit cleans and lubricates the compressed air

and keeps it free of condensation.

For thios tool, the lubricator should be set so

that a drop is applied to the compressed air

approx. every 7-10 minutes.

Damage that occurs as a result of incorrect

compressed-air treatment is excluded from

warranty claims.

We recommend a service unit with a 3/8"

connector for up to two Festool pneumatic tools.

The compressor used to supply the compressed

air should supply at 20 cfm and an operating

pressure of 87 psi. The diameter of the piping

system must be sufficiently large (at least 9mm

/ 1/2).

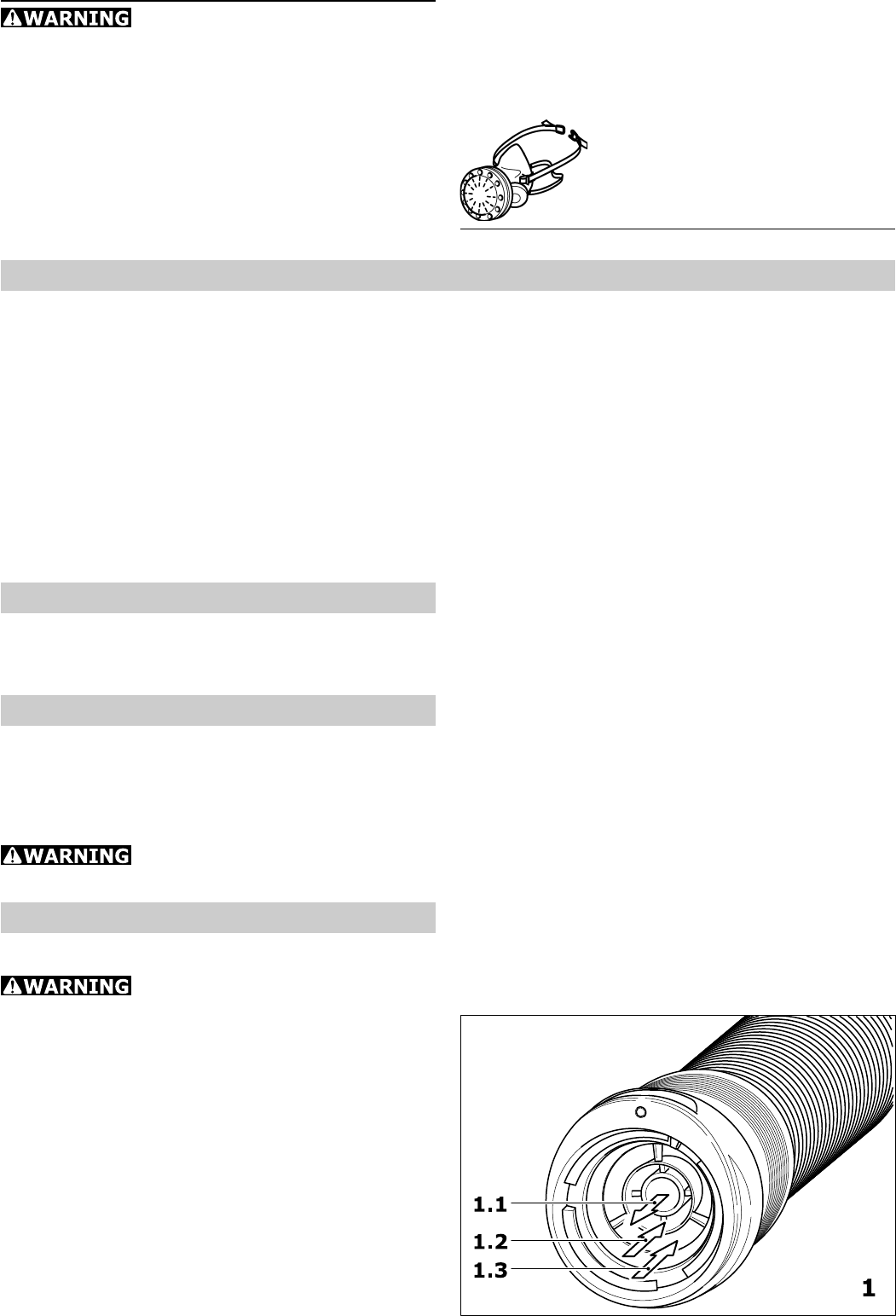

IAS 2 hose connector

The eccentric sander is a pneumatic tool for

connection to the Festool IAS 2 system.

This hose system combines three functions in

one hose:

- Compressed air supply (1.1)

- Exhaust air extraction (1.2)

- Dust extraction (1.3)

Technical data

Sanding pad diameter: - LEX 2 150 150 mm / 6

- LEX 2 185 185 mm / 7

Drive Compressed-air vane motor

Operating pressure (flow pressure) 87 psi

No load speed 4,000 - 8,000 rpm

Orbits per minute 8,000 - 16,000 opm

Sanding stroke: - LEX 2 150/3 3 mm

- LEX 2 150/7, LEX 2 185/7 7 mm

Air consumption at nominal load 14 cfm

Weight: - LEX 2 150 1.3 kg / 2.8 lbs

- LEX 2 185 1.4 kg / 3 lbs

Various dust created by power sanding, sawing,

grinding, drilling and other construction activities

contains chemicals known (to the State of

California) to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and

other masonry products, and

arsenic and chromium from chemically-treated

lumber.

The risk from these exposures varies, depending

on how often you do this type of work.

To reduce your exposure to these chemicals:

Work in a well ventilated area,

and work with approved safety

equipment, such as dust masks

that are specially designed to

filter out microscopic particles.