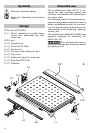

9

10-1

10-6

10-2 10-3

10-4

10-5

10

max. 5 mm

11

Adjustment parallel to the bench edge:

Loosen the rotary knob [10-4].

Adjustment at right angles to the

bench edge:

Loosen the rotary knob [10-4].

Adjusting the stop ruler [10-5]

lengthways

Loosen the rotary knob [10-1]. The stop

ruler can be moved to a lower position for

thin workpieces or a higher position for

thicker workpieces.

Angle adjustment using the scale

Loosen the rotary knob [10-2] and lift the

retaining pin [10-3]. The rotary retaining

pin engages in the most common angle

positions.

Step 8: Adjusting the guide rail

in relation to the workpiece

For sawing and routing applications, the

guide rail can be lowered via [1-2] and

[1-4] so that the rail rests evenly on the

workpiece. The workpiece and the rail are

retained securely.

A support piece of suitable thickness is

placed centrally under the guide rail between

the workpiece and the support unit [1-2] so

that the guide rail does not tilt when narrow

workpieces are machined.

Step 9: Adjusting the cutting

depth for sawing [Fig. 11]

Always make sure that the cutting depth

setting is correct in relation to the workpiece

thickness. We recommend setting a cutting

depth to a maximum of 5 mm more than

the workpiece thickness to protect the pro-

fi le frame from damage.