5

Working with the tool

Always secure the workpiece in

such a manner that it cannot move while being

sanded.

Never overload the tool by using too

much pressure! The best sanding results are

achieved when applying moderate pressure.

The sanding performance and quality depend

mainly on the choice of the right sanding material.

Festool offers the appropriate sanding material for

all applications (see Festool catalogue).

We recommend the following settings on the

rotary control (2.1) for electronic machines:

5 - 6

• sanding with max. drive

• sanding old paint

• sanding wood and veneer prior to painting

• interim sanding of paint on surfaces

4 - 5

• sanding of thinly applied primer

• sanding of wood with sanding vlies

• sanding edges on wooden parts

• smoothing primed wooden surfaces.

3 - 4

• sanding full wooden and veneer edges

• sanding in the grooves/rebates of windows and

doors

• interim paint sanding on edges

• pre-sanding natural wood windows with sanding

vlies

• smoothing wood surfaces with sanding felt prior

to staining

• rubbing down stained surfaces with sanding

vlies

• rubbing down or removing excess lime paste

with sanding vlies

2 - 3

• interim paint sanding on stained surfaces

• cleaning natural wood window grooves with

sanding felt

1 - 2

• sanding stained edges

• sanding thermoplastic synthetics

Maintenance and care

Always remove the plug from the

mains supply socket before carrying out any work

on the machine!

The cooling air vents on the motor housing must

always be free of blockages and clean to ensure

air circulation. Any maintenance or repair work

requiring the motor housing to be opened may

only be carried out by an authorised service

workshop.

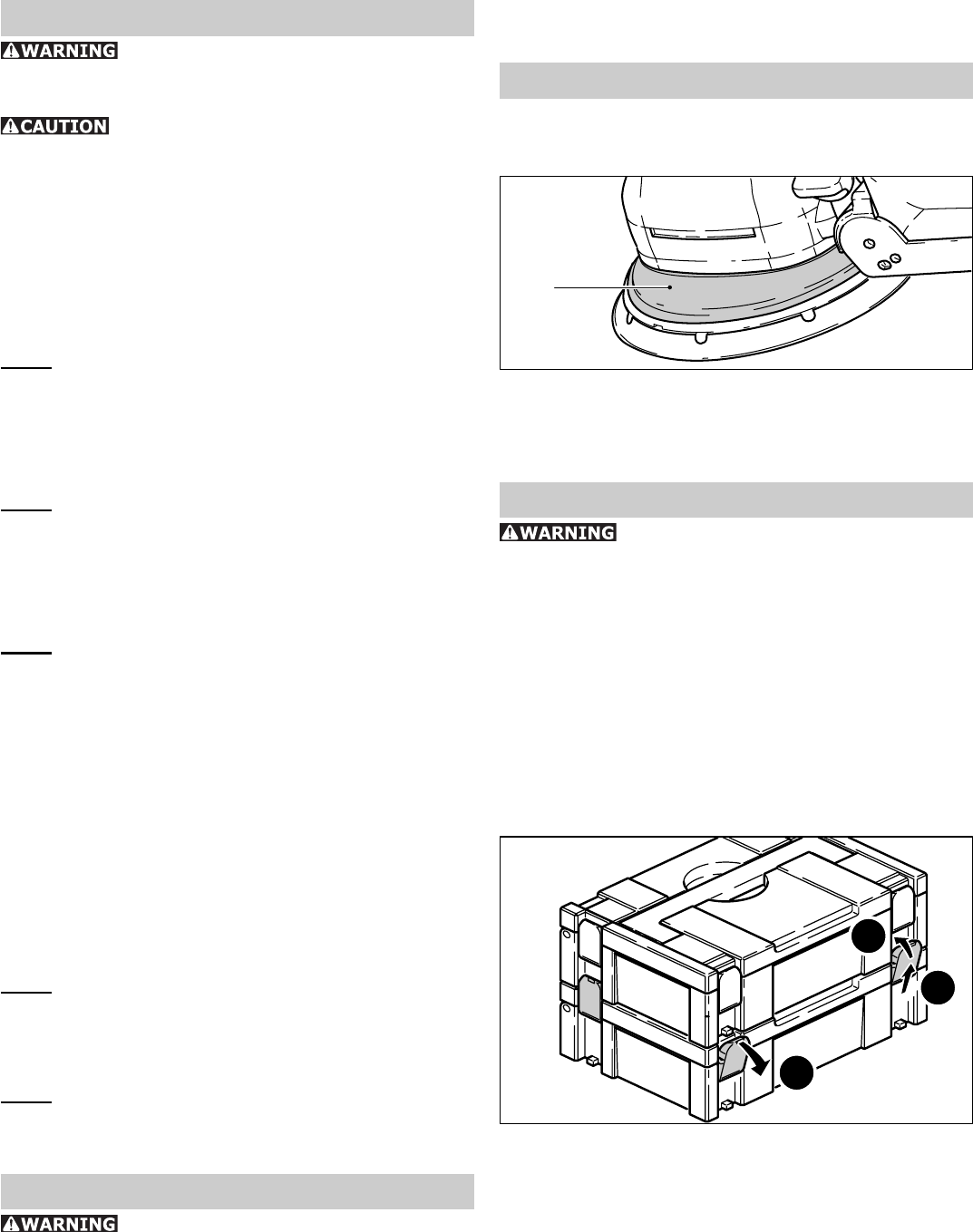

Sanding base brakes

The sanding base is braked by a collar (6.1) in

order to prevent any uncontrolled excessive speed

of the sanding base.

6.1

Because the collar wears down in the course of

time, it has to be replaced by a new one (order

no. 489 190) as soon as there is any reduction in

the braking effect.

Accessories, tools

For safety reasons, only use original

Festool accessories and tools!

The accessory and tool order number can be

found in the Festool catalog or on the Internet

under www.festool-usa.com.

Systainer

Many Festool products are shipped in a unique

system container, called "Systainer". This provides

protection and storage for the tool and acces-

sories. The Systainers are stackable and can be

interlocked together. They also can be interlocked

atop Festool CT dust extractors.

7.1

7.2

7.3

- Place one systainer on top of the other.

- Release all four latches on the lower systainer

by pulling back at their top edges (7.1).

- Slide all four latches upward (7.2).

- Snap all four latches back to their fl at position

(7.3) so they engage the stacking tabs of the

upper systainer.