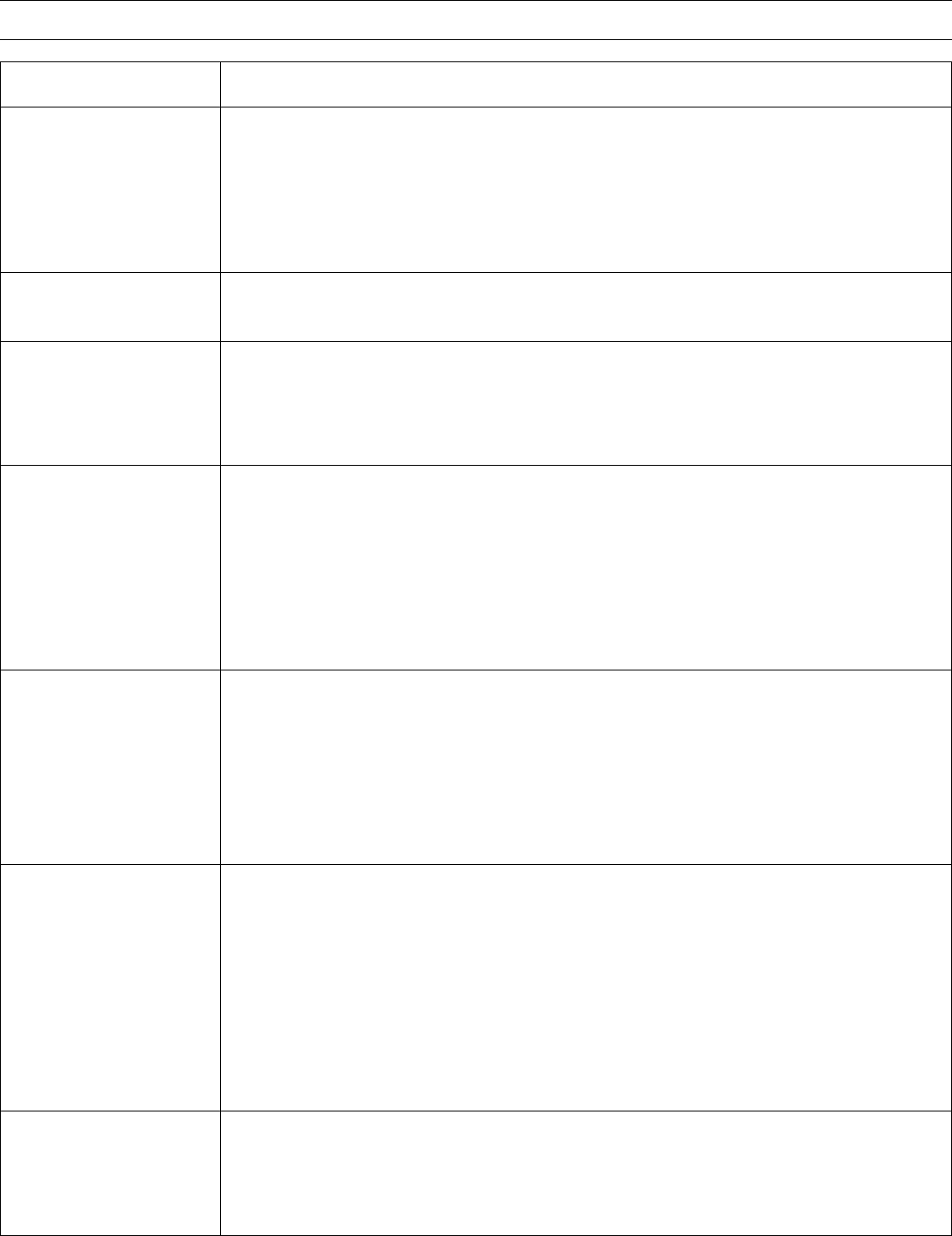

Supplemental Owner’s Manual 19

Troubleshooting

Symptom Possible Causes

Motor does not start

(corded models)

► Check that the cord is properly plugged into an outlet.

► Make sure the Plug-it connector is properly inserted and fully tightened.

► Make sure the outlet has power. Check the circuit breaker or try another outlet.

► If used with a Festool dust extractor, make sure the selector switch is pointing to “Auto”.

The auxiliary outlet on the dust extractor has power only when the selector is at Auto.

► Inspect the power cord (including extension cords) for damage or missing prongs.

Motor does not start

(cordless models)

► Make sure the battery is properly charged and correctly installed on the saw. If possible,

try a different battery to determine if the problem persists.

LED work lights not

functioning properly

► Verify that the LED light function is correctly programmed as described on page 18.

The LEDs have 3 programmable options for “steady-on”, “stroboscopic”, and “off”.

► The LEDs will turn off if the saw is inverted or tilted slightly past the vertical position. This

is to prevent the lights from shining into the operator’s eyes. The LEDs will resume nor-

mal operation the next time the saw is turned on while in the normal horizontal position.

The saw blade will not

eject

► Make sure you have removed the splinter guard before attempting to eject the blade. The

blade cannot rotate with the splinter guard in place.

► Make sure to use the correct sawblade identied for use with a Carvex jigsaw. Some

blades may be too thick or have too much paint on the shank to easily slide out. If a thick

blade rotates to the eject position but does not come out, try to gently pull it out with

pliers.

► Inspect the blade holder to make sure it is in the Park position (fully retracted). If the

blade holder is not in the Park position, unplug the saw and press the tip of the blade

against a work surface to retract it.

Saw blade burns on the

rear of the blade shank

(away from the teeth)

Additional symptoms may include: bluish discoloration of the metal, sparks emanating from

the blade guide area, the blade bends backward even under a light cutting speed.

► The blade guides are set too close for the thickness of the saw blade. Readjust the blade

guides.

► The guides should barely contact the blade without restricting the movement of the

blade.

► Note that for thinner workpieces, the blade guides can be set fairly wide without

adversely affecting the cut quality.

Poor cut quality

► Make sure to use the correct blade for the desired cut:

► Saw blades with a wide set to the teeth will cut more aggressively (faster), but will

leave more scratches in the side of the cut.

► Saw blades with fewer teeth will cut more aggressively, but may be more prone to

chipping in some woods.

► Saw blades with a wider shank (front-to-rear) cut better in a straight line, but are more

difcult for cutting tight curves.

► Don’t force the saw through the cut. Let the blade work at the speed it was intended.

► Use the correct blade speed. Too slow of a speed may result in rough cuts. Too fast can

burn the workpiece.

Dust extractor will not

auto-start when the saw

starts

► If the speed of the saw is set to 1 and the saw is not yet cutting, it may not draw enough

power from the dust extractor to activate the auto-start function. The extractor should

start once the saw begins drawing more power during a cut.

► The saw’s power cord must be plugged into the extractor’s auxiliary outlet. The auto-start

feature will not function with battery powered jigsaws.