6

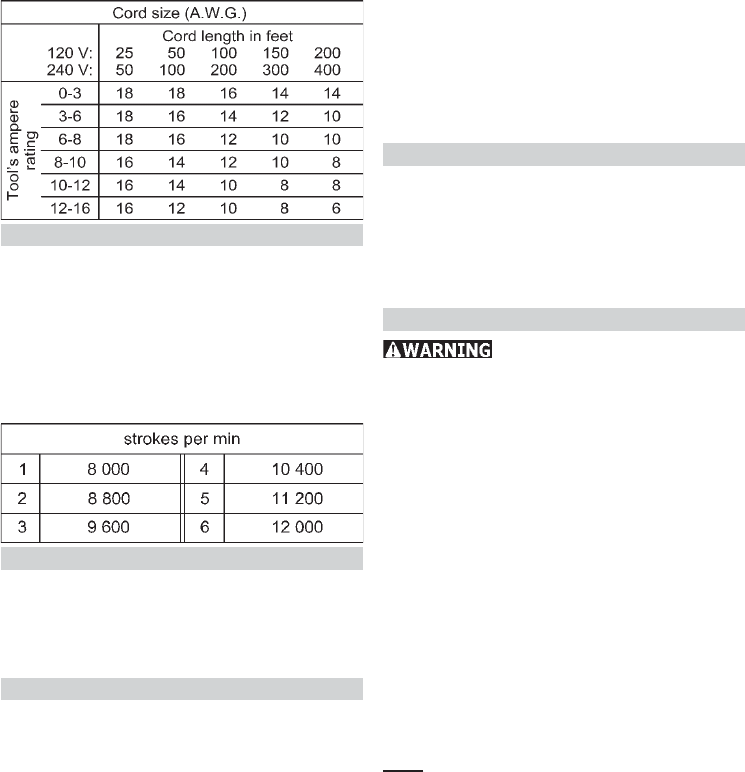

cord length and tool's ampere rating. Use only

U.L. and CSA listed extension cables. Never use

two extension cables together. Instead, use one

long one.

Note: The lower the A.W.G. number, the

stronger the cable.

Electronic control

The LS 130 EQ has an electronic control with

which the rotational speed can be varied step-

free. This allows the sanding speed to be

adapted to the optimum level according to the

material concerned.

The speed is set using the rotary control button

(1.3). The numbers on the rotary control button

represent approximately the following strokes

per min:

Dust extraction

Dust extractors prevent large accumulations of

dust in the air in the working environment and

dirt collecting in the workplace. In this case,

the extraction pipe (Ø 27 mm) of the extraction

unit is connected to the suction nozzle (1.4).

Sanding pad

In order to be able to sand various profiles,

Festool offers shaped sanding pads (see Festool

catalogue or on the Internet under

www.festool-usa.com).

These sanding pads can be changed quickly

and easily without tools.

Removing the sanding pad (Fig. 3):

- Push the sanding pad forwards (e.g. by

pressing the rear edge of the sanding pad

against a flat surface),

- keep the sanding pad pressed forwards and

swivel the front edge of the sanding pad away

from the tool,

- release the pressure slightly, remove the

sanding pad from the rear.

The new sanding pad is fitted in the reverse

order.

Make sure that the four lugs (3.1) of the sanding

base catch in the four recesses (3.2) in the

sanding pad.

To ensure a better grip of the sanding pad on

the sanding base of the LS 130 EQ you can

fasten the sanding pad in the four holes in the

corners (1.7) using the enclosed screws. The-

se screws have to be removed before

exchanging sanding pads.

Attaching sanding material

The appropriate Stickfix sanding paper and

Stickfix sanding felt can be fastened quickly

and easily onto the Stickfix sanding base.

The self-adhesive sanding material (1.5) is

simply pressed onto the sanding base (1.6) and

held safely in place by the Stickfix sanding base

velcro surface.

Working with the machine

Never overload the tool by using

too much pressure!

The best sanding results are achieved when

applying moderate pressure. The sanding

performance and quality depend mainly on the

choice of the right sanding material. Festool

offers the appropriate sanding material for all

applications (see Festool catalogue or on the

Internet under www.festool-usa.com).

Metalworking

The following precautions are to be taken when

processing metals for safety reasons:

- connect a residual current operated device in

series before the tool,

- connect tool to a suitable dust extractor,

- clean tool regularly of dust accumulations in

the motor housing.

Speed adjustment

We recommend the following settings of the

rotary control (1.3) for electronic machines:

3 - 6

- sanding old paint

- sanding wood and veneer prior to painting

- interim sanding of paint on surfaces

- Sanding profiled workpieces of natural wood.

- sanding of thinly applied primer

- smoothing primed wooden surfaces.

- sanding full wooden and veneer edges

- sanding in the grooves/rebates of windows

and doors