11

Press the contact slide down until it latches f

into position.

Insert the handle section [1-6] at the same f

way.

If you wish to use the L

PLANEX

for sanding

walls in cramped spaces, for example, reduce

the length of the machine by fi tting the sanding

head [1-1] directly to the handle section [1-6].

When disassembling the machine, do not forget f

to press the button [4-1] to release the contact

slide before opening clamping levers [3-1] and

[3-2].

Electronics

The machine features full-wave electronics with

the following properties:

Smooth start-up

The electronically controlled smooth start-up

function ensures that the machine starts up

smoothly.

Speed control

You can regulate the rotational speed steplessly

between 310 and 920 rpm using the adjusting

wheel [1-3]. This enables you to optimise the cut-

ting speed to suit the respective material.

Constant speed

The preselected motor speed remains constant

through electronic control. This ensures a uniform

cutting speed even when under strain.

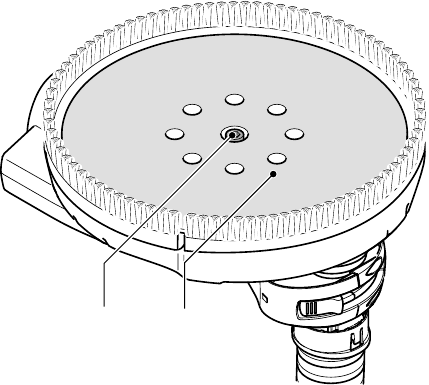

Changing sanding pads

Insert an Allen key (size 5) into the Allen screw f

[5-1] on the sanding pad.

Hold the sanding pad securely and turn the f

Allen key to release.

In order to further ensure optimum axial run- L

out, you must fi rst clean the bearing surface

for the grinding disk on the driveshaft.

Attach the new sanding pad. f

Tighten the screw f [5-1].

Only attach specifi ed sanding pads to the ma- L

chine.

In order to guarantee optimum suction output, L

the sealing face between the machine and

the grinding disk is ground in during the fi rst

few minutes after the disk has been changed.

During this time, the r.p.m. of the machine is

slightly lower and white foam particles form

during the grinding process. However, they do

not damage the machine.

5

5-1 5-2