9

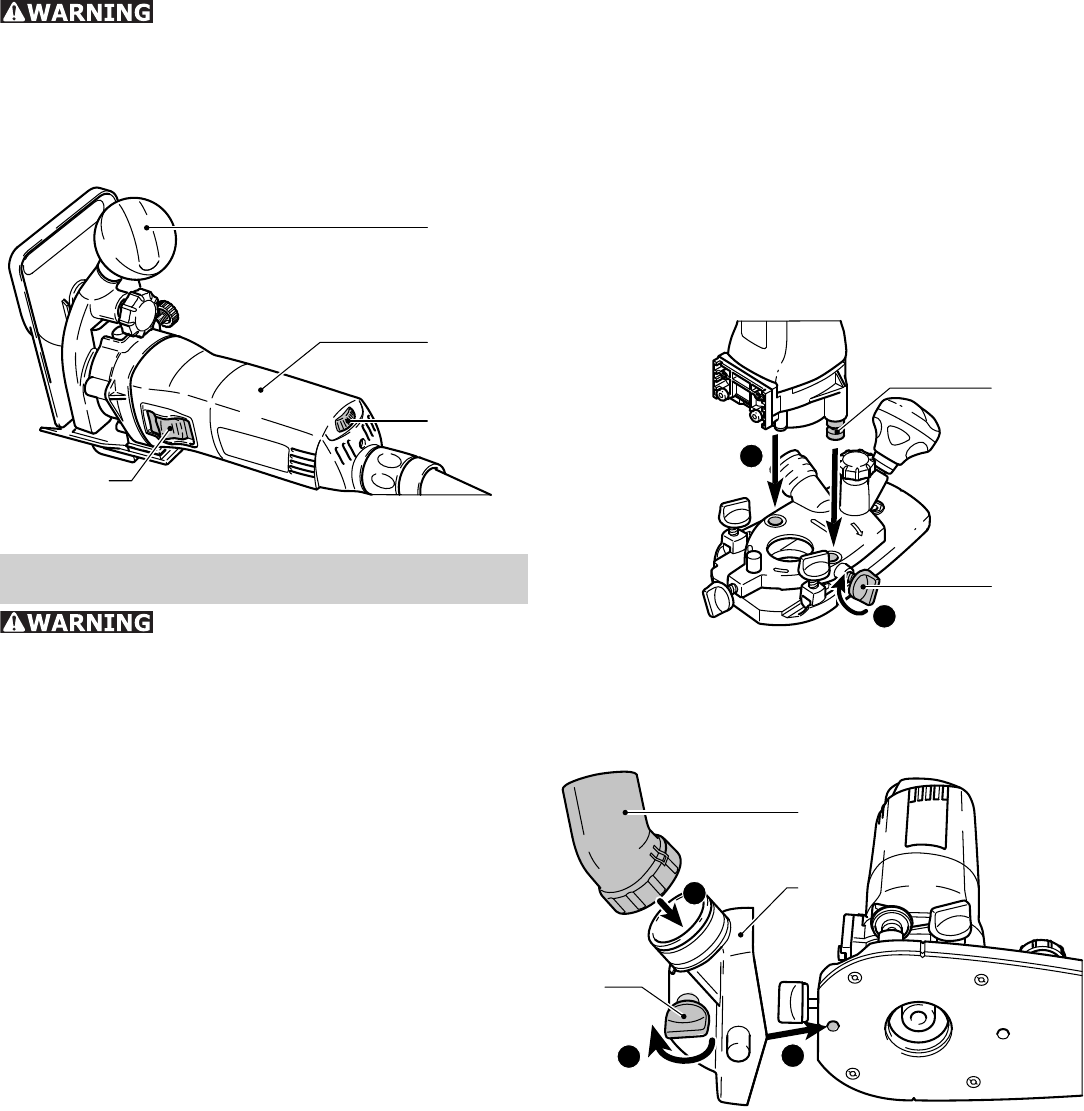

Switching the ma-

chine on and off

Keep the machine steady

during switching and during use by hold-

ing the handles [3-1] [3-2] with both

hands.

The switch [3-4] is an on/off switch (I = ON,

0 = OFF).

3-1

3-3

3-2

3-4

Tool settings

Disconnect the plug from the

power source before making any adjust-

ments, changing accessories, or storing

power tools.

Electronic control

The machine features full-wave electronics

with the following properties:

Smooth start-up

The electronically controlled smooth start-up

function ensures that the machine starts up

smoothly.

Speed control

You can regulate the rotational speed

steplessly between 10000 and 26000 rpm

using the adjusting wheel [3-3]. This enables

you to optimise the cutting speed to suit the

respective material.

Constant speed

The preselected motor speed remains con-

stant through electronic control. This ensures

a uniform cutting speed even when under

strain.

Temperature control

To prevent overheating, the safety electronics

switches the machine off when it reaches a

critical motor temperature. Let the machine

cool down for approx. 3-5 minutes before us-

ing it again. The machine requires less time

to cool down if it is running, i.e. in neutral

position.

Changing the router table

The “large surface router table” is already fi t-

ted as standard. The large contact surface and

precision adjustment features of this router

table enable a high degree of accuracy. Other

router tables are included in the accessories

programme.

a) Large surface router table

4-2

4-1

2

1

Slide the router table onto the retaining pin –

[4-1] on the machine.

Tighten the screw [4-2] to clamp the router –

table in position.

4-5

4-4

4-3

5

4

3

Place the extraction hood [4-4] in posi- –

tion.

Tighten the screw [4-3] to clamp the ex- –

traction hood in position.

Place the extractor connector [4-5] on the –

extraction hood.

Removal is performed in reverse sequence to

installation.