8

Planer heads and spi-

ral cutters

Use only cutters which are sharp

and undamaged. Blunt cutters increase the

danger of kick-back and reduce the planing

quality obtained.

The planer is equipped with planer head HK

82 SD as standard series. The planer head

has inclined, fi tted cutters, which is why the

cutters cannot be reground.

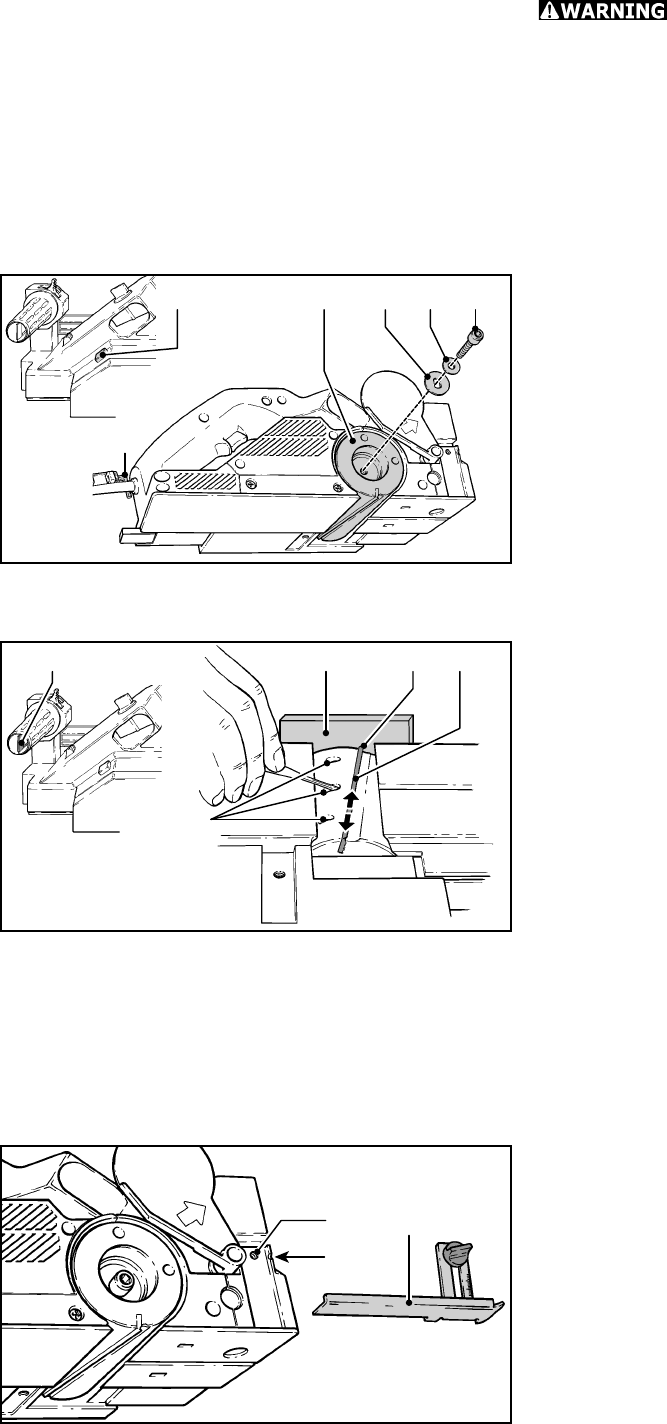

a) Changing the planer head

Use the spindle stop (3.5) to lock the planer

shaft and unscrew the allen bolt (3.1) from

the planer head (3.4) using the allen key

(3.6). Remove the planer head from the

planer shaft.

Before fi tting the new planer head clean the

planer shaft to remove any dust residues.

The planer head can be fi tted to the planer

shaft in reverse order using the clamping

fl ange (3.3), washer (3.2) and allen bolt

(3.6).

b) Changing the planer blade

Use the allen key (4.1) to loosen the three

allen bolts (4.5) in the planer head until the

planer blade can be removed.

Before the new blade is fi tted the cutter slot

must be cleaned. This ensures that the cut-

ter is automatically correctly adjusted after

fi tting.

Push the new planer blade (4.4) into the

groove in the tool carrier with the labelled

side facing towards the rear planer platen.

Before you retighten the clamping screws use

a ruler (4.2) to align the blade in such a way

that its face lies fl ush with the front and rear

planer platen (4.3). Finally tighten fi rst the

centre clamping screw and then two outer

clamping screws.

Fitting the guides

The scope of delivery of the planer includes a

rebating depth guide and a parallel guide.

a) Rebating depth guide

The rebating depth guide (5.1) is mounted

in the threaded hole (5.2) on the front right

of the machine. The stop can be infi nitely

adjusted to between 0 mm and 30 mm in ac-

cordance with the scale. The rebating depth

3.1

3.6

3.33.43.5 3.2

4.5

4.2 4.3 4.44.1

5.3

5.1

5.2