13

8. When all slots have been cut, clean the edge and slots of

any remaining sawdust.

9. Place the biscuits into position and fit the matching timber

pieces together.

10. Clamp the boards and wipe clean any excess glue and

leave to set as per the glues specifications.

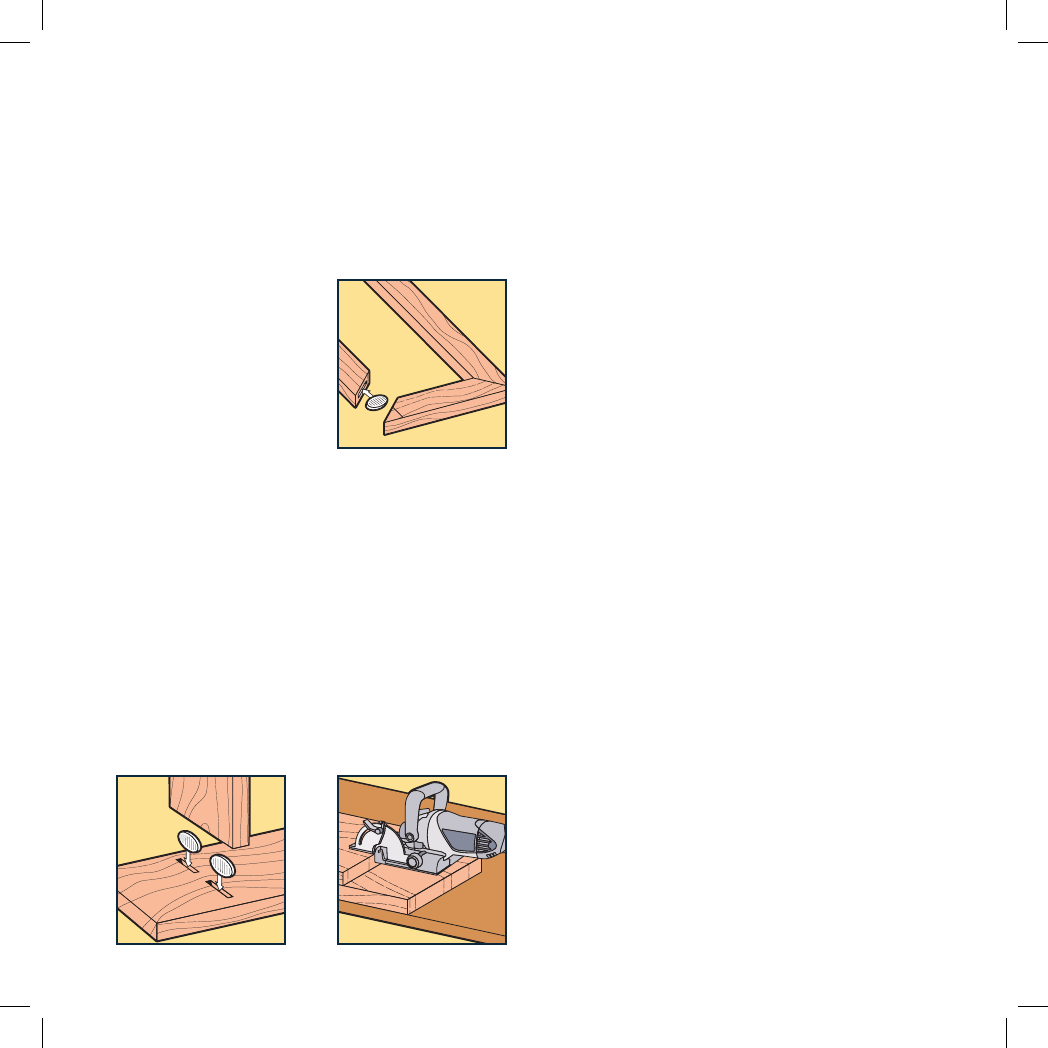

Making a corner joint

1. Set the 2 pieces together and

draw the joint centres on the

outside face and end.

2. Cut the slots into the end

piece.

3. Cut the slots in the face piece.

4. Once all the slots are cut

insert a biscuit into each joint

and dry assemble the workpieces to ensure everything

lines up and fits.

5. Insert a water-based glue into the slots.

6. When all slots have been cut, clean the edge and slots of

any remaining sawdust.

7. Place the biscuits into position and fit the matching timber

pieces together.

8. Clamp the boards and wipe clean any excess glue and

leave to set as per the glues specifications.

Making a T-joint

1. Place the 2 pieces to be joined on a level bench.

2. Mark the centreline for each biscuit.

Horizontal BoardHorizontal Board

Clamp.

To cut end slots in

horizontal boards

3. Cut the slots into the workpiece that will become the

vertical board.

4. Cut the slots into the workpiece that will become the

horizontal board

5. Once all the slots are cut insert a biscuit into each joint

and dry assemble the workpieces to ensure everything

lines up and fits.

6. Insert a water-based glue into the slots.

7. When all slots have been cut, clean the edge and slots of

any remaining sawdust.

8. Place the biscuits into position and fit the matching timber

pieces together.

9. Clamp the boards and wipe clean any excess glue and

leave to set as per the glues specifications.

Maintenance

All the bearings are sealed ball bearings, lubricated for life,

and require no maintenance.

Regularly check that all the fixing screws are tight.

They may vibrate loose over time.

Power cord maintenance

If the supply cord needs replacing, the task must be carried

out by the manufacturer, the manufacturer’s agent, or an

authorised service centre in order to avoid a safety hazard.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all times.

2. Remove dust and dirt regularly. Cleaning is best done

with a rag. Wear safety goggles or an eye shield and

gloves whist cleaning.

3. Keep all moving parts free of built up sawdust and other

foreign matter.

4. Never use caustic agents to clean plastic parts.

CAUTION. Do not use cleaning agents to clean the plastic

parts of the tool. A mild detergent on a damp cloth is

recommended. Water must never come into contact with

the tool.

Centreline

mark(s)

Biscuit slot