. ..

This

equipment

has

been carefully manufac-

AIR

REQUIREMENTS

ranted against defective

materials

and/or uork- from

x)

to

1oo.s.i.

CAUTION:

Do

not

use

more

tured to exacting

GRACO

standards.

It

is

WW-

Air

pressures required to owrate

PmP

range

manship

as

set

forth

in

the

GRACO

WARRANTT.

than

100

lb. of air Dressure to ODerate

PWP.

Excessive

wear

due to passage of abrasive

or

not be construed

as

indication of defective parts ing pressures and operating speeds.

this

dt

corrosive

materials

through

this

equipment

shall

h-ing

continuous operation,

at

nod

m-k-

within the limitations of

this

warranty. require actual

air

delivery of approxhatew

h

IMPORTANT

NOTES

c.f.m.

per

gun

plus

3

c.f.m.

for

continuous

use

of

agitator.

"

materkl

hose

is

expensive.

HANDLE

To provide reserve capacity for

peak

load

WPPH

CARE.

GRACO

WARRANTI

does not cover abuse conditions compressor should delivery 25% me

air

such

as

sharp

khking,

crimping

or

crushing.

ment which

it

is

to

serve.

than

required

for

normal

operation

Of

all

equip-

hire to effectively ground the

unit.

If

addi-

Air

supply hose 205-216 Includes

a

static

tional

air

supply hose

is

required,

it

should

be

of

the sane type.

since

in

this Hvdra-Sorap process air

is

not need-

ed to atomize the

paint.

N&:

Consumtion of compressed

air

is

lm,

PREPARATION FOR OPERATION

1.

Remove contents arton

and

cokzct before reaching unit.

NOTE:

A

Graco

air

line

the hire-braided hpont " lined

material

strainer

2OL-999 (accessory) may be purchased

hose 205-349 (15')

or

204-938 (25'

)

to nipple separately for removing foreign

matter

from

air

164-672 protruding

from

material outlet manifold entering

the

unit. Attaches to

air

manifold

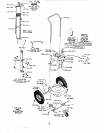

205-485. Connect the end, without swivel 2QL-9LO 162-376 as shorn

in

Fig.

2.

attached, to nipple 164-672. See

Fig.

1.

DO

NOT

connect swivel 204-940, attached to other end

of

205-216--

I

e'

NBT

this hose, to spray

gun

at

this

time.

DO

NOT

USE

THREAD

SEM

AT

ANY

WIVF,L

CONNECTION.

*THESE

ARC

bCCtSSCUIU

2

NOTE:

Check

dump

valve of

manifold

205-485

...

it

should be closed. When closed,

its

knob

is

in

a

horizontil position. Refer to

Fig.

1.

NOTE:

Models 226-163. 226-165

&

226-167 are

vith foot

on

rod protruding from bracket attached

equipped with

a

brake-to set brakes push

down

2. For operation

of

a

second sprav

mn

to back of truck base and guide rod into notch at

purchase these accessories separately...two

(2)

bottom of bracket.

high

pressure

material

shutoff valves 205-583.

a second hose 205-349 (15')

or

2OL-938 (25'),

a

L.

If

Model 226-161

or

226-163 with hand-

second swivel 2OL-940,

a

second spray

ep

205-162 merated elevator,

lift

up

on

elevator hanger and

and

a

second spray tip of

customers

choice.

Re-

hook over handle.

NOTE:

If

elevator

is

difficult

move nipple 16L-672 and plug from manFfold to raise, apply a little grease to exterior

sur-

M5-485, and qonnect valves and hoses

as

shorn faces of handle ends.

~. .

.~

in

Fig.

2.

..

3. Attaah one end

of

15

foot air supply hose elevator, disconnect

air

line coupler 202-417,

205-216

to

smce of air Supply and screw other attached to end of air hose 160-023,

from

ab line

end

Of

hose

into

air manifold swivel adapter fitting

in

agitator 205-307 and connect to

air

162-376.' Refer to Fig.

1.

Kale hose studs are line fitting

157-367.atop

elevator as shown

in

Fix.

threaded

NET.

Install a

master

air valve

(drain

or

bleed typelin the air supply

line

in

1.

With air admitted to unit, elevator will raise

unit and hold

it

there until air hose

160621

is

Snch location

that

air

can be turned

on

and off

disconnected.

If

Model 226-165

or

226-167 with air-operated

4

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE