8 309411

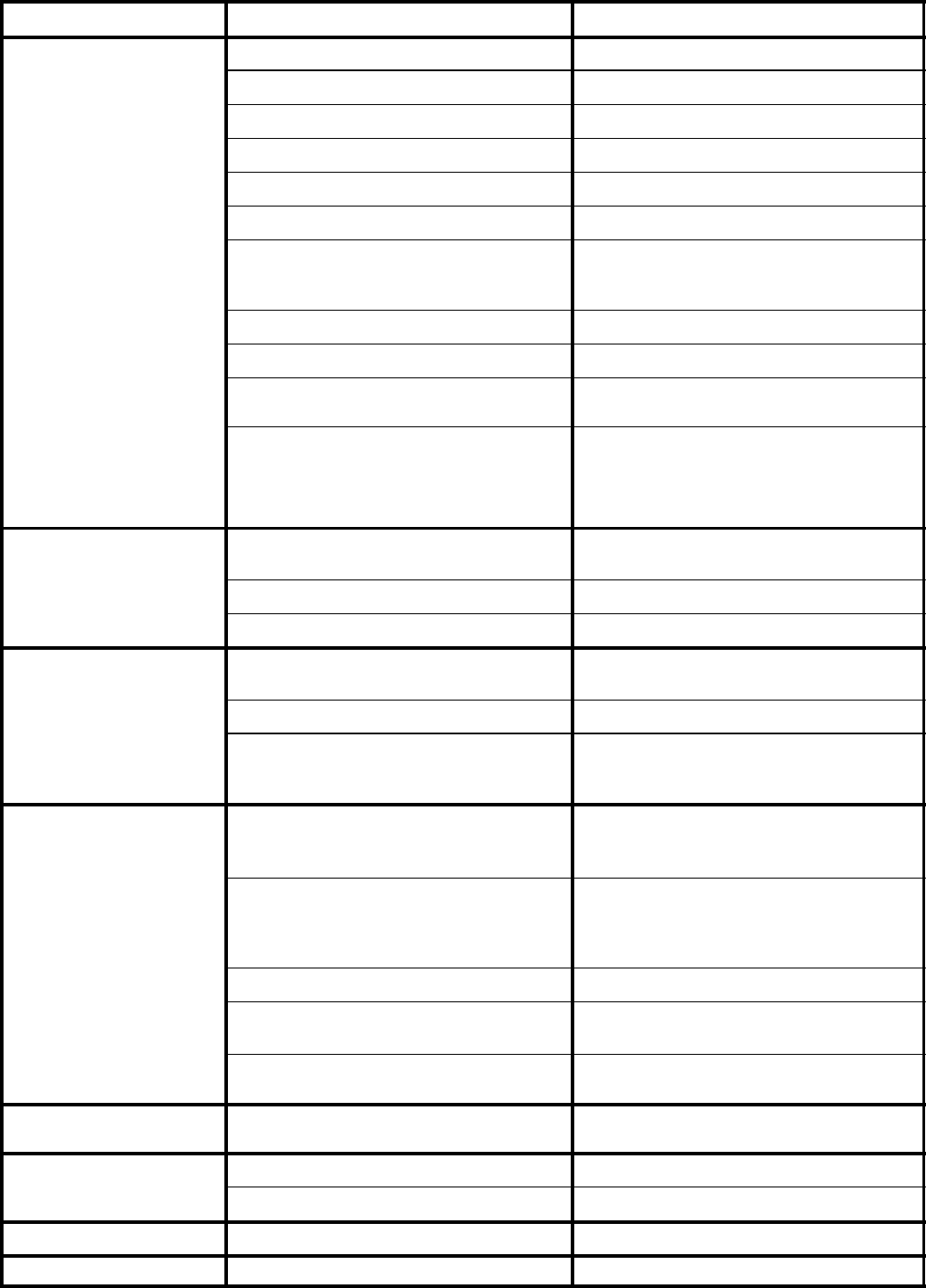

PROBLEM CAUSE SOLUTION

Pump output low

Strainer (31) clogged Clean.

Piston ball (25) not seating Service piston ball check. Manual 309277.

Piston packings worn or damaged Replace packings. Manual 309277.

Displacement pump o-ring (227) is damaged Replace o-ring. Manual 309277.

Intake valve ball not seating properly Clean and service. Manual 309277.

Engine speed is too low Increase throttle setting. See Manual 309410.

V–belt slipping Tighten V–belt with tension bar (101). Adjust

bracket until it takes 15 lb of force to lock

tension bar down.

Clutch worn or damaged Replace. See page 11.

Pressure setting is too low Increase pressure. Manual 309410.

Fluid filter (318), tip filter or tip is clogged or

dirty

Clean filter. Manual 309410 or 309091.

Large pressure drop in hose with heavy

materials

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum perfor-

mance (50 ft minimum).

Excessive paint leakage into

throat packing nut

Throat packing nut is loose Remove throat packing nut spacer. Tighten

throat packing nut just enough to stop leakage.

Throat packings worn or damaged Replace packings. Manual 309277.

Displacement rod worn or damaged Replace rod. Manual 309277.

Spitting from gun Air in fluid pump or hose Check and tighten all fluid connections.

Reprime pump. Manual 309410.

Tip partially clogged Clear tip. Manual 309091.

Fluid supply is low or empty Refill and prime pump. See Startup, Manual

309410. Check fluid supply often to prevent

running pump dry.

Pump is difficult to prime Air leak Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

Intake valve is leaking Shut off pump and relieve pressure. Disas-

semble and clean intake valve. Be sure ball

seat is not nicked or worn and that ball seats

well. Reassemble.

Worn packings Repack pump. Manual 309277.

Fluid is too thick Thin fluid according to supplier’s recommenda-

tions.

Engine speed is too high Decrease throttle setting before priming pump.

Manual 309410.

Clutch squeaks each time

clutch engages

Clutch surfaces are not matched to each other

when new and may cause noise

Clutch surfaces need to wear into each other.

Noise will dissipate after a day of run time

High engine speed at no

load

Misadjusted throttle setting Reset throttle to 3700 engine rpm at no load

l

oa

d

Worn engine governor Replace or service engine governor

Gallon counter not working Bad sensor, broken or disconnected wire Check connections. Replace sensor or wire.

No display, sprayer operates Display damaged or has bad connection Check connections. Replace display.