Installation

4 308613E

Installation

Accessories are available from Graco. Be sure all

accessories are properly sized to withstand the pres-

sures in the system.

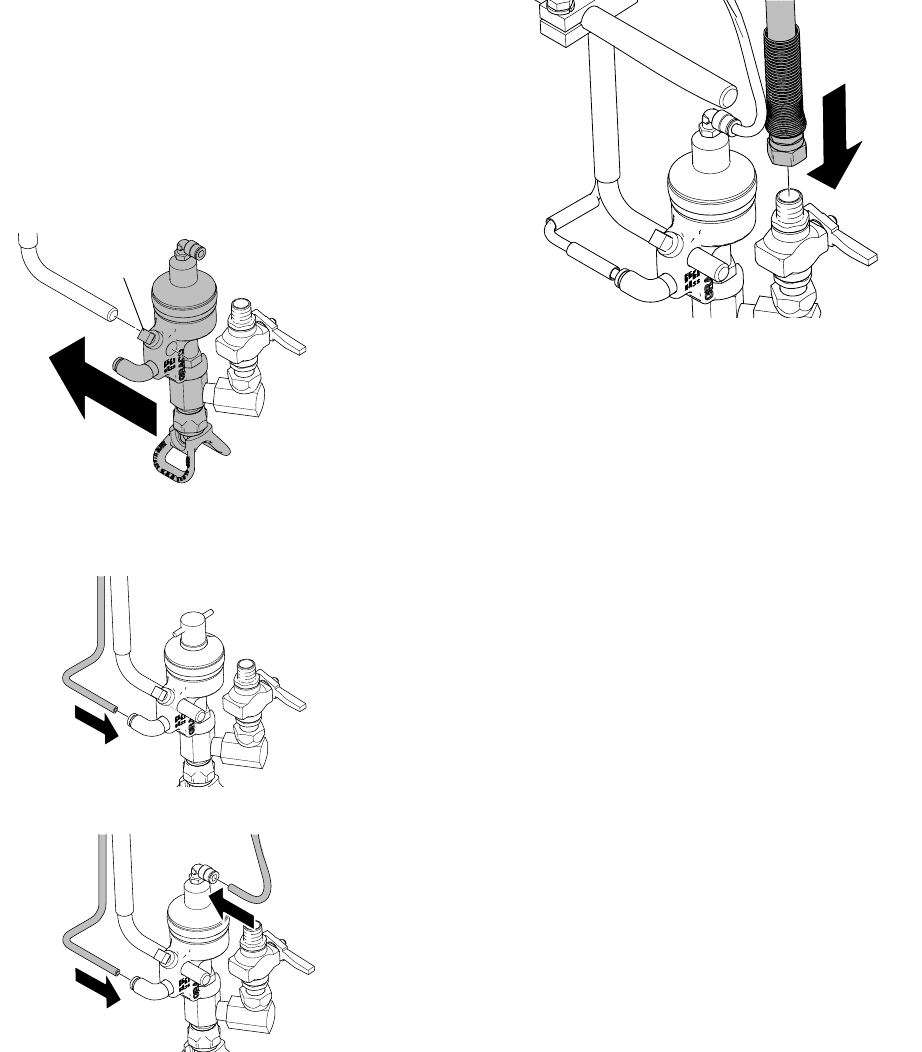

Mount Valve

Mount the valve on a 0.50 in. (12.7 mm) diameter rod on

a mounting fixture or a dispensing machine. The paint

gun has a clamping set screw (6) for mounting.

Connect the Air Lines

Clean all lines and connections of dirt, burrs, etc. and

blow them out with clean air before connecting them to

the system. Install an air filter in the air supply line to

remove harmful dirt and moisture from the compressed

air.

Connect Fluid Lines

Connect a grounded fluid line from the pump to the fluid

adapter of the paint spray gun. You should install a fluid

pressure regulator to control fluid pressure to the paint

spray gun. The regulator enables you to control fluid

pressure more accurately than by regulating hydraulic

pressure to the pump.

Install a fluid filter to remove particles and sediment

which may clog the tip.

Install a manual ball valve to shut off fluid flow to spray

gun.

Grounding

Proper grounding is essential to maintaining a safe sys-

tem.

To reduce the risk of static sparking, ground the pump,

paint spray gun, and all other system equipment.

1. Pump: Use a ground wire and clamp.

2. Air compressors and hydraulic power supplies:

Follow manufacturer’s recommendations.

3. Air and fluid hoses connected to the pump: Use

only grounded hoses with a maximum of 500 feet

(150 m) combined hose length to ensure grounding

continuity.

4. Dispensing valve: Obtain grounding through con-

nection to a properly grounded fluid hose and pump.

5. Fluid supply container: According to local code.

6. All solvent pails used when flushing: Ground

according to local code. Use only metal pails, which

are conductive. Do not place the pail on a non con-

ductive surface, such as paper or cardboard, which

interrupts the grounding continuity.

ti16341a

6

ti16342a

Double-Acting Gun

Single-Acting Gun

ti16776a

ti16343a